REMARK

Operate the lever only with the arm IN direction to release the remaining pressure.

3.

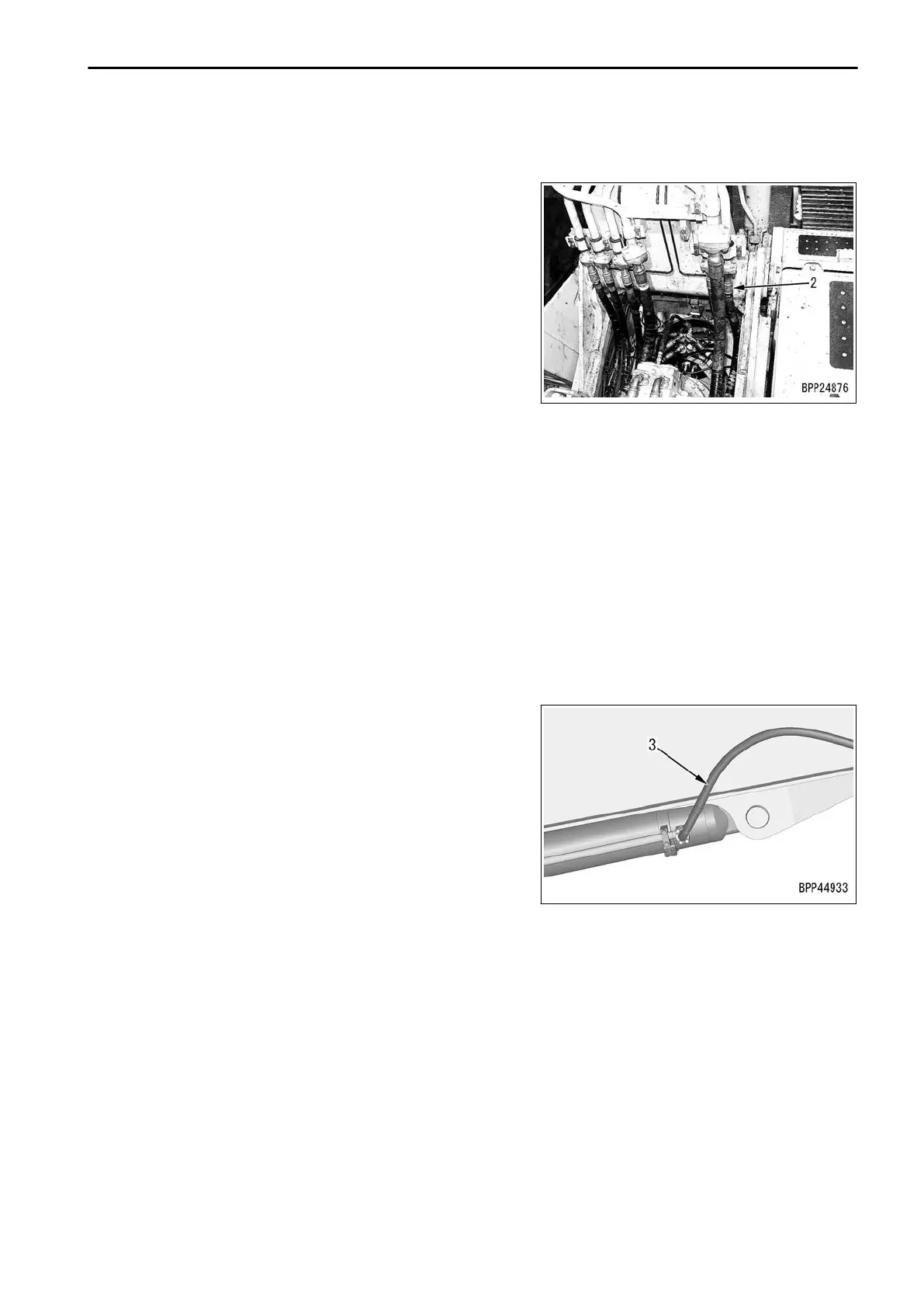

Disconnect the hose (2) on the cylinder head side. Block

the hose side with the flange B.

Be careful not to disconnect the hose on the cylin-

der bottom side.

4.

Start the engine.

5.

Select and display “Pre-defined Monitoring” (01/11) by re-

ferring to “SET AND OPERATE MACHINE MONITOR”.

6.

Adjust the hydraulic oil temperature so that it is within the

specified range.

7.

Turn the fuel control dial to MAX (High idle) position.

8.

Operate the work equipment control lever to relieve the oil

pressure in the arm IN circuit.

Be careful not to operate the lever to “Arm OUT” side.

9.

Measure the oil leakage for 1 minute 30 seconds after the oil pressure is relieved.

See ST

ANDARD VALUE TABLE, “STANDARD VALUE TABLE FOR MACHINE” for standard values.

Restore the machine after finishing the test.

METHOD FOR TESTING OIL LEAKAGE FROM BUCKET CYLINDER

1.

Set the bucket cylinder at CURL stroke end, and stop the engine.

2.

Release the remaining pressure from the piping on the bucket cylinder head side by referring to “RELEASE

REMAINING PRESSURE FROM HYDRAULIC SYSTEM”.

REMARK

Operate the lever only with the bucket CURL direction to release the remaining pressure.

3.

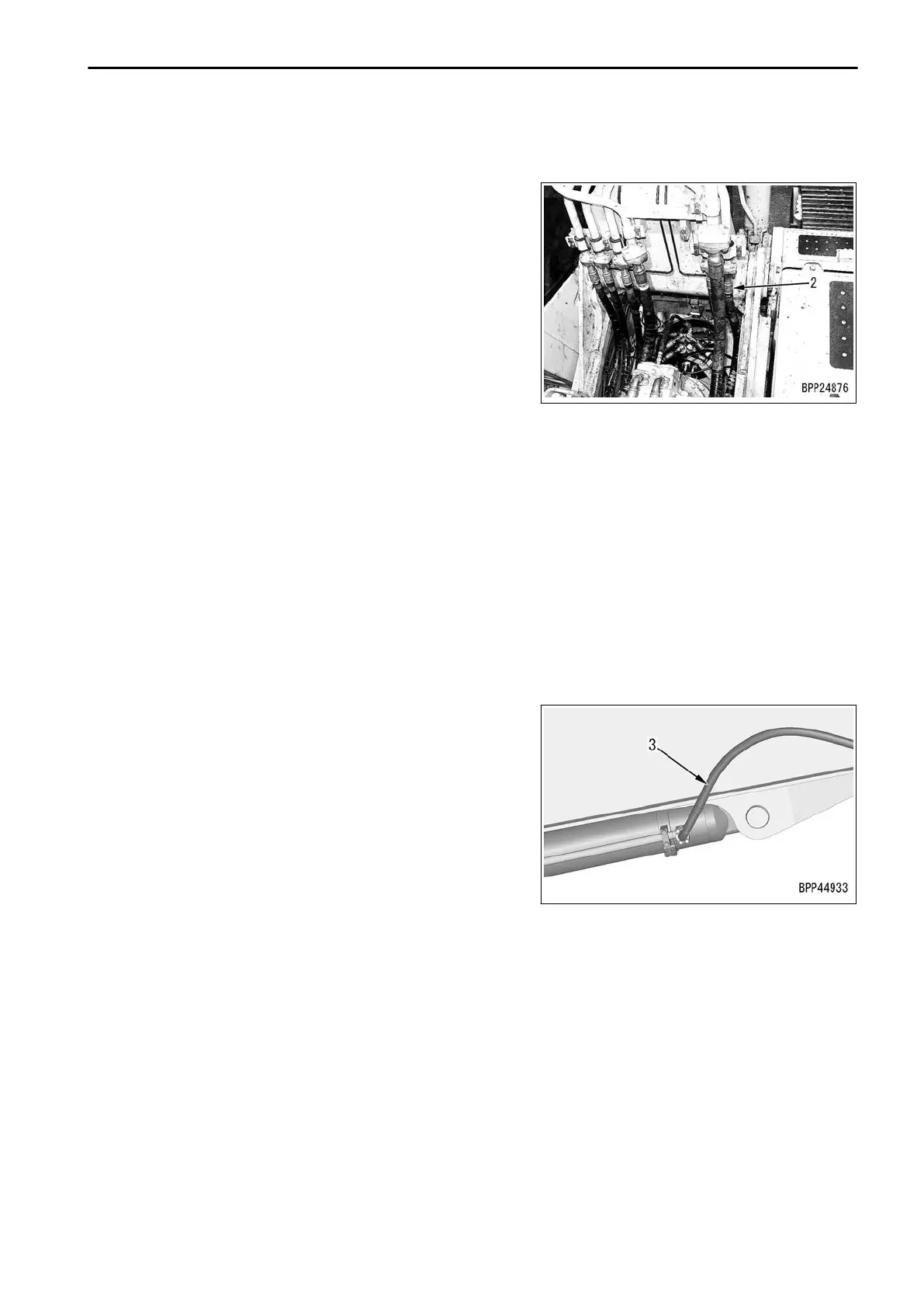

Disconnect the hose (3) on the cylinder head side. Block

the hose side with flange B.

Be

careful not to disconnect the hose on the cylin-

der bottom side.

4.

Start the engine.

5.

Select and display “Pre-defined Monitoring” (01/11) by re-

ferring to “SET AND OPERATE MACHINE MONITOR”.

6.

Adjust the hydraulic oil temperature so that it is within the

specified range.

7.

Turn the fuel control dial to MAX (High idle) position.

8.

Operate the work equipment control lever to relieve the oil pressure in the bucket CURL circuit.

Be careful not to operate the lever to “Bucket DUMP” side.

9.

Measure the oil leakage for 1 minute 30 seconds after the oil pressure is relieved.

See STANDARD VALUE TABLE, “STANDARD VALUE TABLE FOR MACHINE” for standard values.

Restore the machine after finishing the test.

METHOD FOR TESTING OIL LEAKAGE FROM SWING MOTOR

1.

Release the remaining pressure in the circuit by referring to “RELEASE REMAINING PRESSURE FROM

HYDRAULIC SYSTEM”.

30 TESTING AND ADJUSTING TEST OIL LEAKAGE

PC500LC-10R 30-97

Loading...

Loading...