.

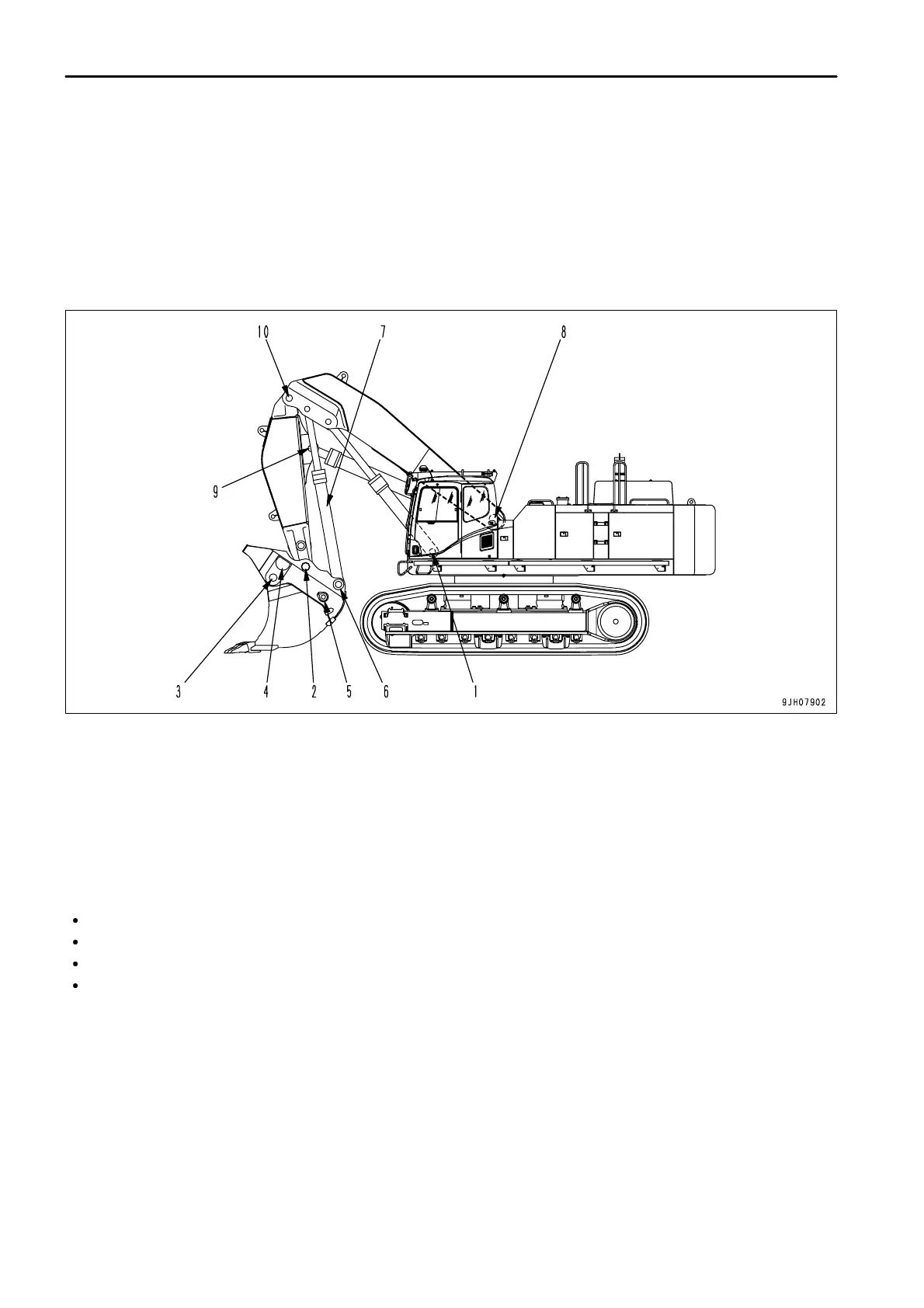

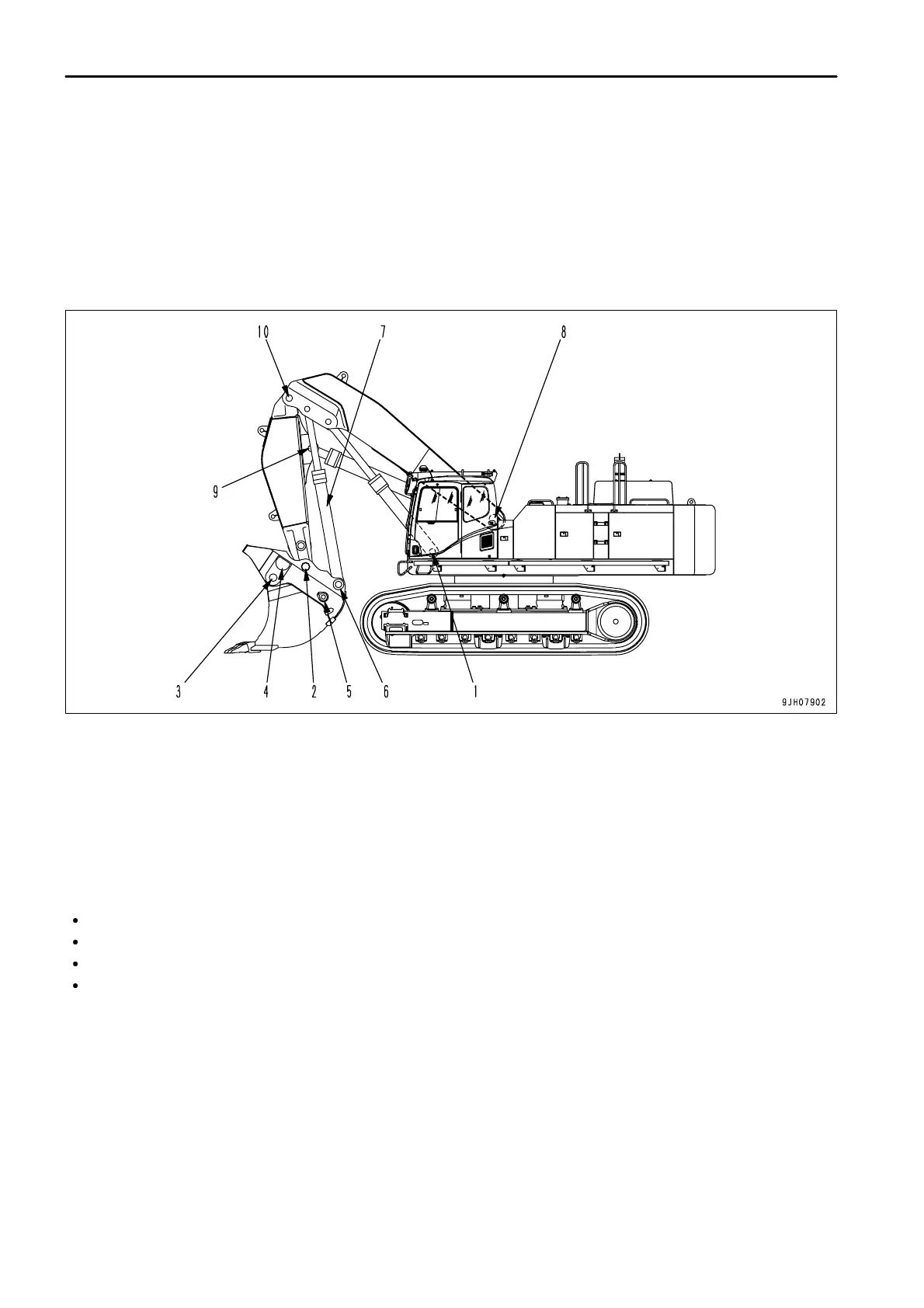

LOADING SHOVEL

MAINTENANCE

EVERY 10 HOURS MAINTENANCE

LUBRICATTING

1. Set the work equipment in the greasing posture below, then lower the work equipment to the ground and stop

the engine.

2.

Using a grease pump, pump in grease through the grease fittings shown by arrows.

3. After greasing, wipe off any old grease that was pushed out.

(1) Boom cylinder foot pin (2 places)

(2) Arm-Bucket coupling pin (2 places)

(3) Bucket hinge pin (2 places)

(4) Bottom dump cylinder rod end pin (2 places)

(5) Bottom dump cylinder foot pin (2 places)

(6) Bucket cylinder foot pin (2 places)

(7) Bucket cylinder rod end, link connection pin (4 places)

(8) Boom centralized greasing block (7 places)

Boom foot pin

Arm cylinder foot pin

Boom cylinder rod end

Bucket cylinder rod end

(9) Arm cylinder rod end (1 place)

(10) Boom-Arm coupling pin (2 places)

7 - 18

Loading...

Loading...