INSTRUCTIONS

Video instruction available:

http://koslow.com/metal_test_kits/ThermoElectric_Alloy_Sorter?cPath=1

1. Remove protective plastic boot from the metallic hot probe tip.

2. Plug the TEAS into 110 Volt AC line power.

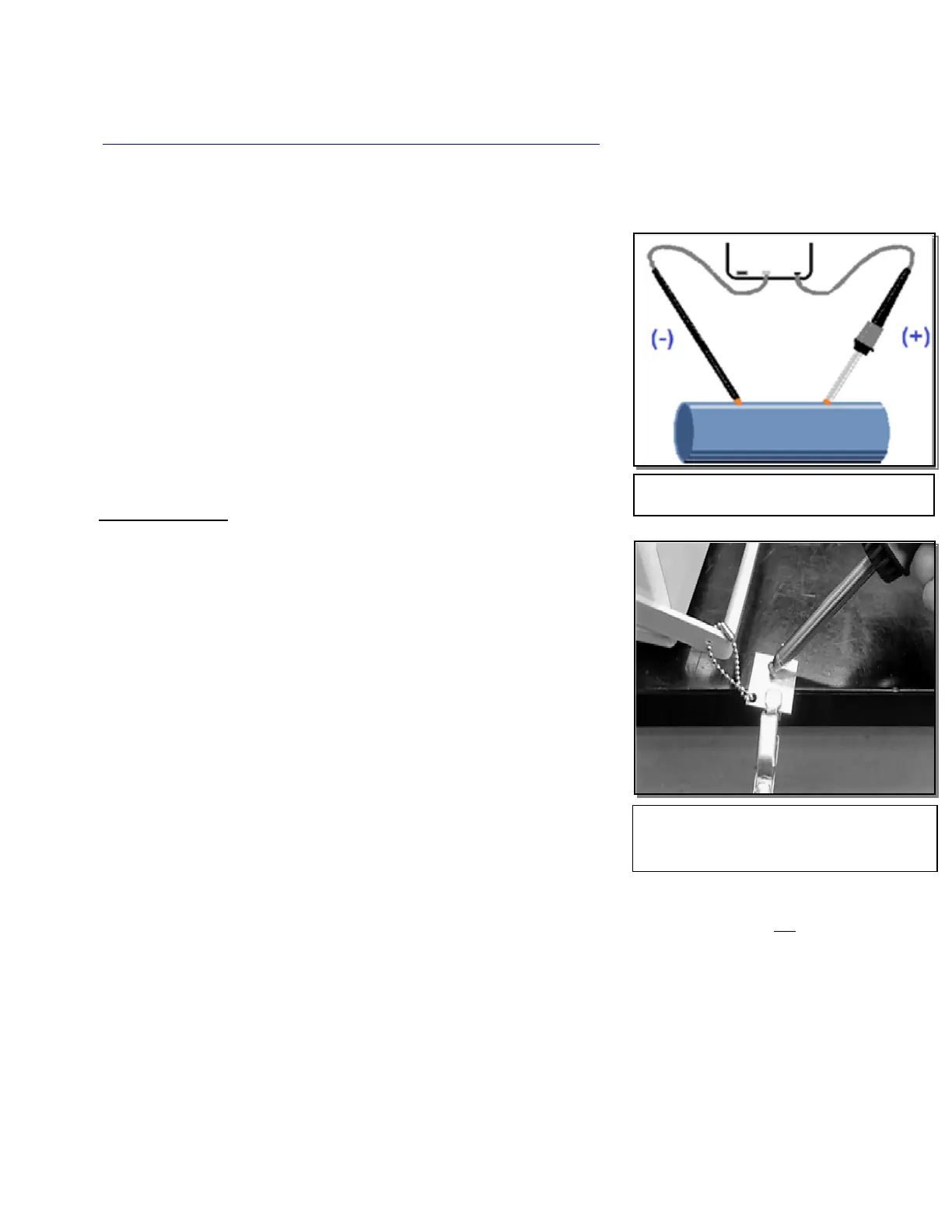

3. Connect the Cold Circuit. Either the Alligator Clip, The Wand or Block to

the BNC connector on the bottom side of the instrument. The BNC fitting

requires pushing and twisting.

4. Turn on the power switch. Caution: the probe will get hot. Do not touch

the metal shaft or tip. The amber light will remain constant for about one

minute. The side holster is helpful for safely securing the thermal probe

when not in use. Keep tip away from kit foam or other damageable

materials.

5. Wait about five (5) minutes for the Hot Probe temperature to stabilize

fully. At this time, the amber light will blink regularly, signaling the probe is

at the correct operating temperature. The display LCD should read 0000 +/-

2.

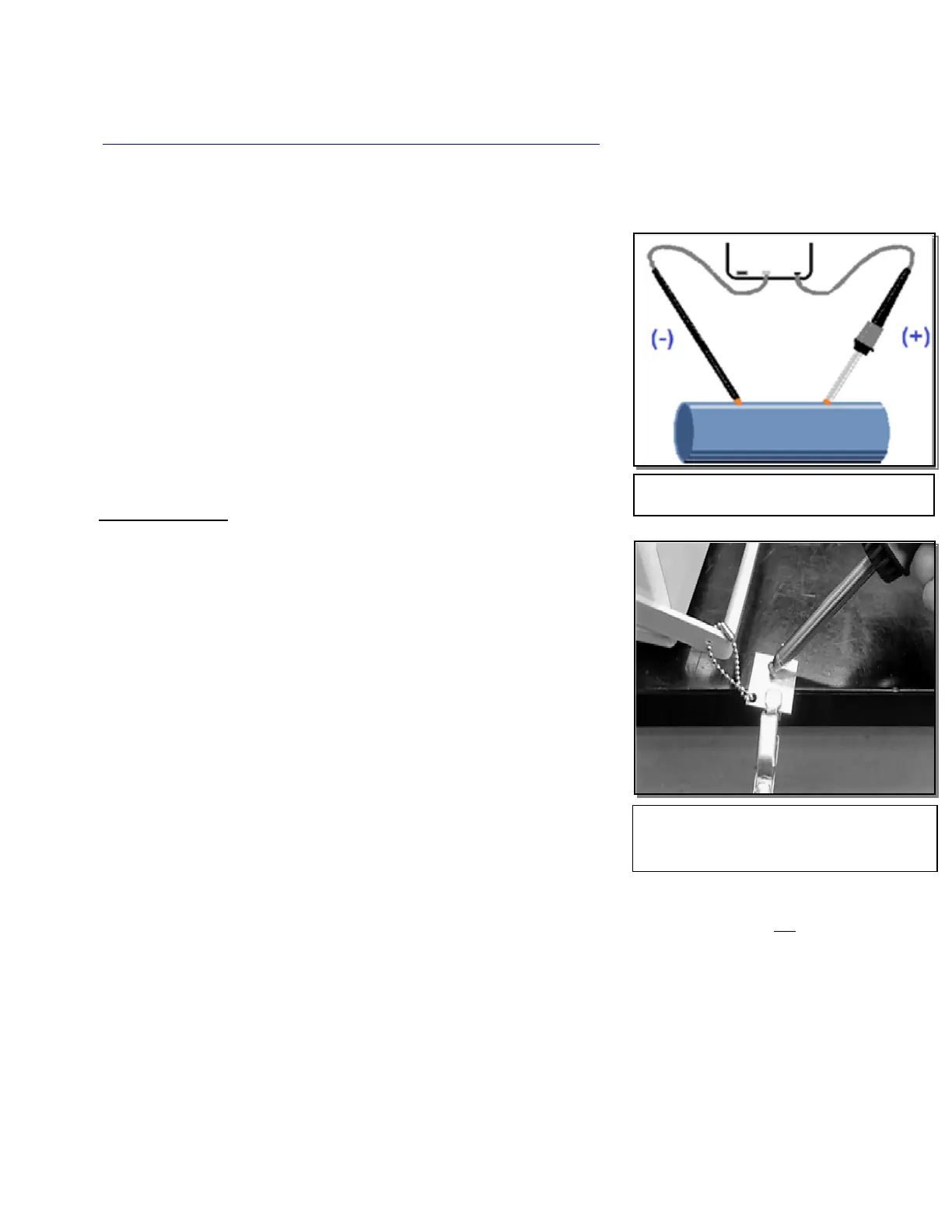

6. Operation Check: Place the provided Daily Qualification Standard (DQS)

into the jaw of the alligator clip. The standard is on a ball-chain attached to

the instrument handle. Fig. B.

7. Contact the Hot Probe tip to the test metal for only two seconds. Apply

just a little more pressure than when using a ballpoint pen, around (70 psi).

The display should read 60 +/- 10. This re-standardization step shall be

performed at the start and finish of each run and at least once during every

hour of continuous operation. This concludes the Operation Check.

8. Next, prepare your actual test metal. Test metal and probe tips must be

clean and free of scale. Wipe metal surface with a cloth or abrade with an

abrasive.

9. Select best Cold Circuit lead for your application (page 8 for details)

Either:

A) Alligator Clip

B) The Wand

C) The Heavy Block

10. Contact the Hot Probe tip against the test metal for one second and read the displayed numeral. It might be

necessary to press down on the sample one or two times for a precise reading. It is important not to keep the

probe in contact with the metal for more than two seconds. After two seconds, the readings become erroneous

because the values can drift due to heat dissipation. Wait two seconds between tests to allow the probe

temperature to stabilize.

11. Compare the displayed TE numeric readings to acceptable metal standards, or the supplied chart. The chart

provided is suggested values and is useful as a guide. The TE-3000 is a capable instrument as long as the

variations of one metal have a 10 point ‘buffer’ from the fluctuations of a second metal. It is also possible that

different alloys give the same TE reading. Some materials might provide slight variations in TE readings due to

heat treatment during alloy formation. Ambient conditions can change, influencing test results.

12. When the instrument is not in use, turn off the power. The Hot Probe takes a few minutes to cool down.

Fig B. Maintain better contact with the

DQS if Alligator Clip over-hangs the

Fig A. The Thermo-Electric Circuit

Loading...

Loading...