18

Suction of detergents

with detergent supply from the suction side:

Detergent injection on the pressur side, as you probably know it from other HP cleaners,

consume approx. 30 % of the cleaning energy, no matter if they are used or not. Due to the

water tank fitted to the Kränzle therm cleaners it is now possible to directly suck the

detergent into the pump thus reducing output loss and increasing the efficency considerably

.

The detergents are applied without having to reduce the working pressure

.

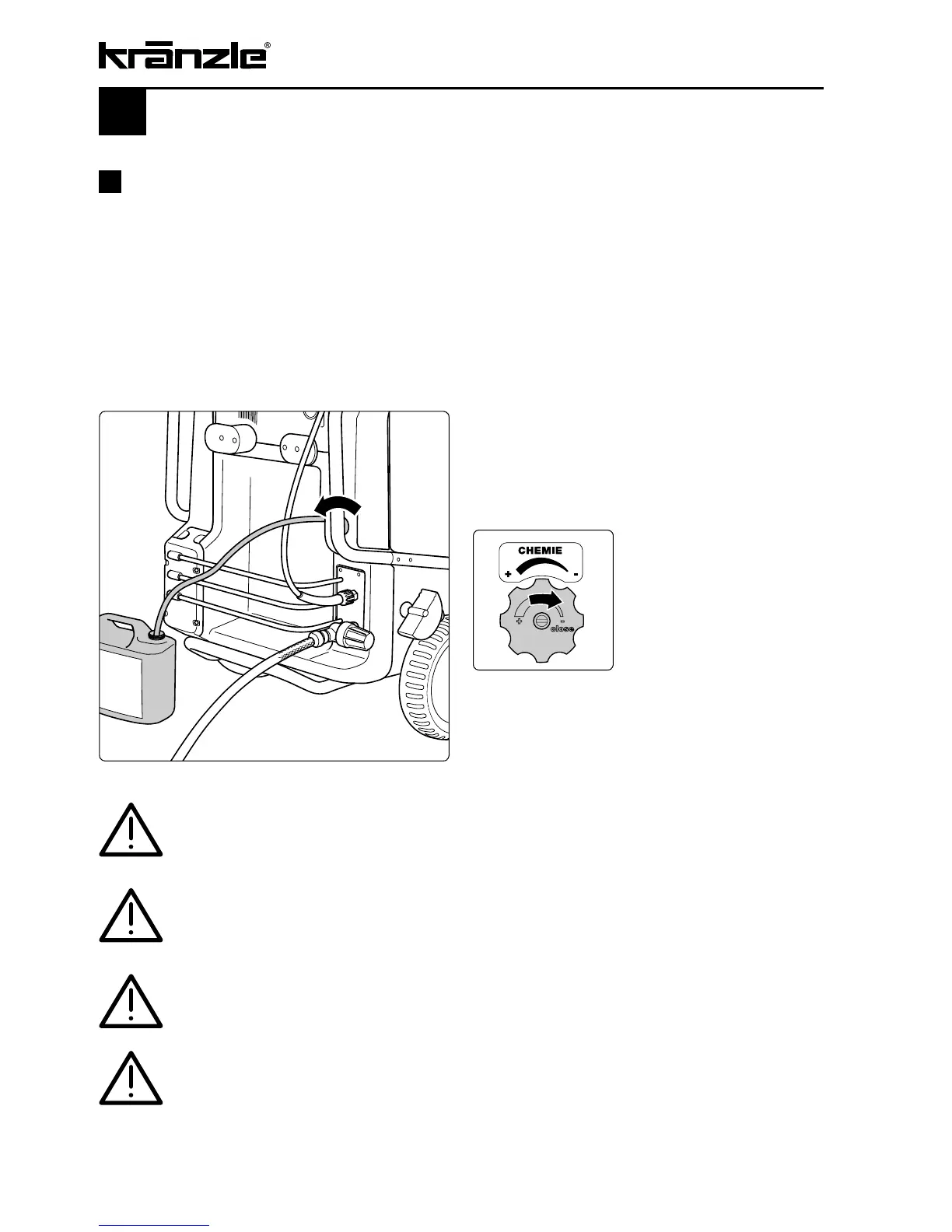

1.

Place detergent filter into detergent

container

.

2.

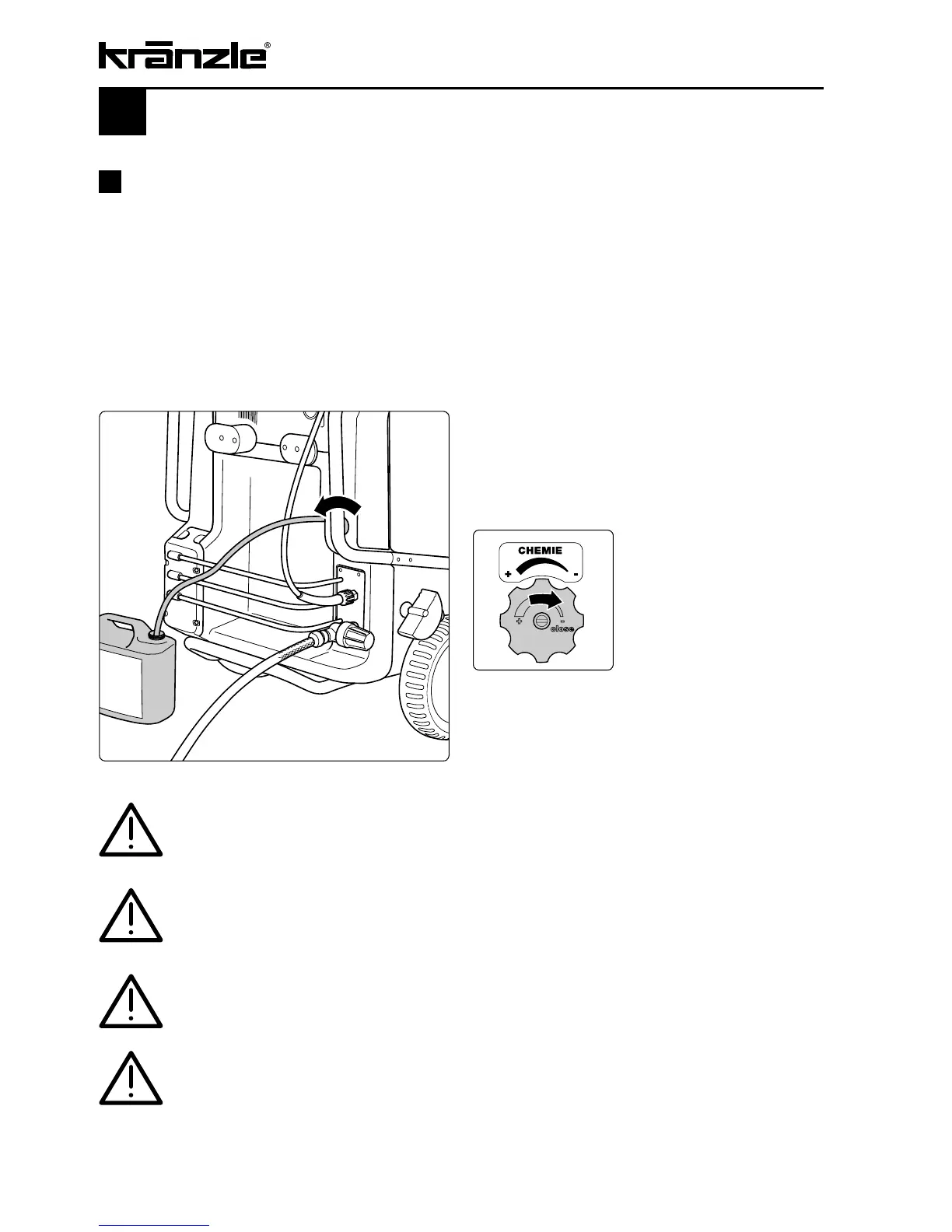

Dosing of detergent is done by turning

the detergent valve

.

3.

By closing the deter-

gent valve the supply of

detergent is stopped

.

4.

After having used detergents rinse the

appliance with open spray gun and clear

water for at least 2 minutes.

Only open the dosing valve, if the detergent sieve is placed in a liquid.

Sucked air leads to destruction of the pump seals! No guarantee!

Keep detergent-ph-value neutral 7 - 9!

Observe specifications of detergent manufacturer!

e.g.: protective equipment, rules for waste water treatment etc.

Never suck in liquids containing solvents like varnish solvents, petrol,

oil or similar liquid! Observe specifications of detergent manufacturers

!

Seals inside the appliance are no resistant against solvents! The spray

mist of solvents is highly inflammable, explosive and poisonous.

Loading...

Loading...