Form #: SIDOM.4 Page | 17 Revised: 03/19

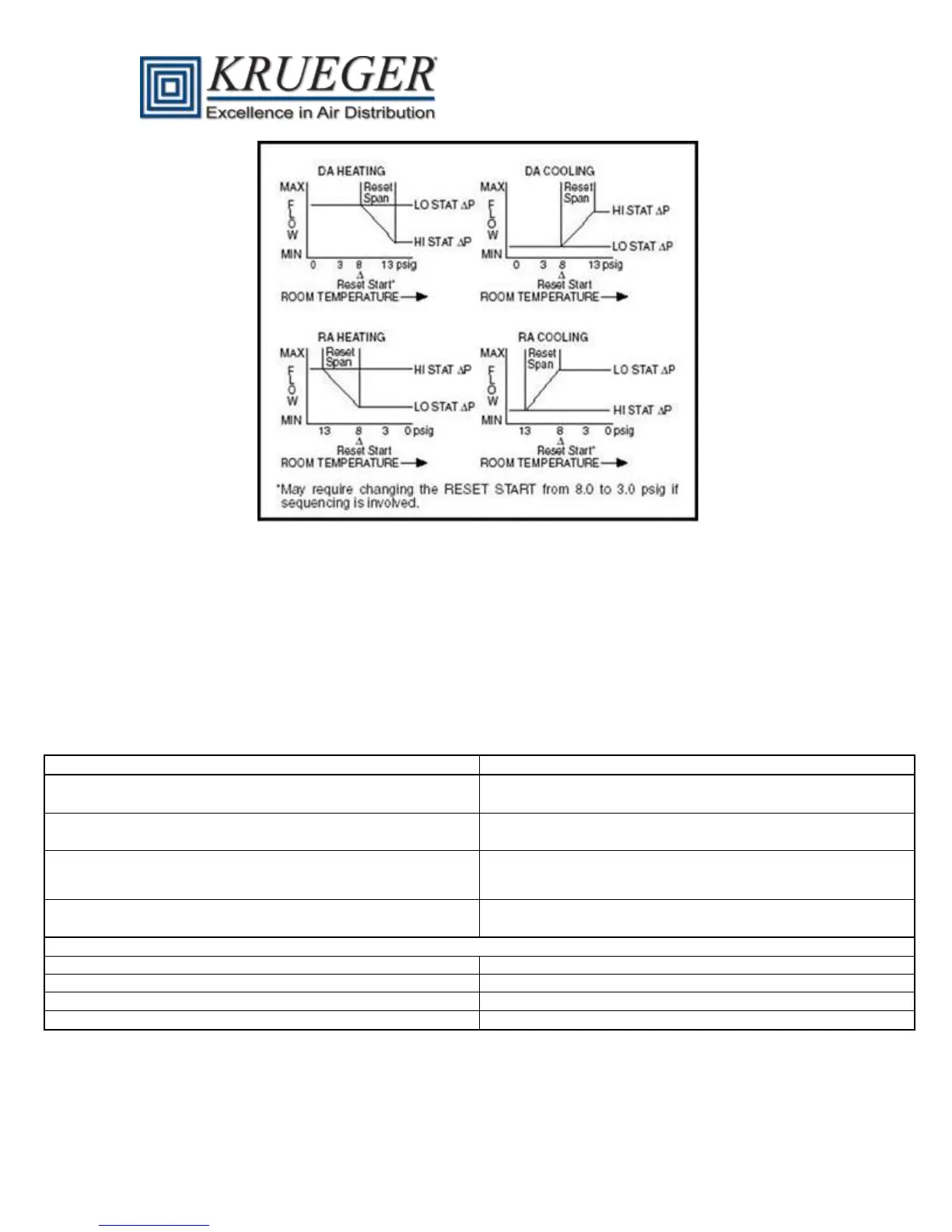

Figure 9 – Reset Cycle for CSC 3011 Control

Preventative Maintenance

1. Inspect pneumatic tubing for loose connections or leaks.

2. Clean out pneumatic line filters regularly according to manufacturer’s recommendations.

Pneumatic Control Troubleshooting

Table 3 – Pneumatic Control Troubleshooting

Controller does not reset to maximum or minimum set point during

balance procedure.

Balancer is using the thermostat for control signal. An artificial

signal must be provided in place of the thermostat.

Controller does not reset to maximum or minimum set point during

operation.

Thermostat is not demanding maximum or minimum air volume.

Main air pressure at the controller is less than 15 psi.

Pneumatic actuator does not stroke fully.

Leak in pneumatic line between the controller and the actuator.

Main air pressure at the controller is less than 15 psi. Leak in the

diaphragm.

Air valve stays in wide open position.

Inlet airflow sensor is blocked by an obstruction (plastic bag, etc.).

Insufficient supply air in the inlet duct.

● Main air pressure (15 psi to 25 psi) at the controller.

● Proper thermostat signal and logic (Direct/Reverse Acting).

● Disconnected or kinked pneumatic lines to the controller

● Blocked inlet airflow sensor or insufficient primary supply air.

● Quality of compressed air (oil or water in lines).

● Leaks in the actuator diaphragm.

● Mechanical linkage of the actuator/air valve.

Loading...

Loading...