Installation/Operating Manual

2017.01

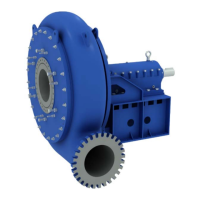

MDX [en-US]

Pump Ty

pe:

Pump Serial Number:

Date:

Purchaser:

Purchaser’s Order Num

ber:

GIW / KSB

W

ork Order Number:

Shipped To:

Include the pump’s serial number when

ordering replacement parts

This is a standard maintenance manual provided for your convenience

This manual may include additional documentation not applicable to your specific pump

GIW INDUSTRIES, INC.

5000 Wrightsboro Road

Grovetown, GA 30813 USA

+1 (888) 832-4449

FAX +1 (706) 855-5151

www.giwindustries.com

KSB AG

Johann-Klein-Str. 9

D-67227 Frankenthal, Germany

+49 6233 86-0 .

FAX +49 6233 86-3289

www.ksb.com