MDX [en-US]

49

11 Tooling

11.1 Torque Requirements

Torque requirements listed below and in previous sections are for lubricated bolting. All bolts must be lubricated to ease in pump

assembly and disassembly. Anti seize compound is preferred, but well oiled is also acceptable.

Special Torque Requirements

Fastener torque must be accurately measured to achieve the proper clamping force as defined either on the assembly

drawing or previous sections listed below. The use of a Hydraulic Torque Wrench is recommended as these tools can

be calibrated to produce the necessary accuracy.

For bearing housing hold down bolt torque refer to Section 8.4 "Bearing Assembly Mounting".

If the pump is equipped with an impeller release ring refer to 10.3 "Wet End Assembly" for torque requirements.

If the pump is equipped with a mechanical seal is used refer to the Mechanical Seal Manual for torque requirements.

Non-Critical Torque Requirements

No special torque requirements exist for the remaining nuts and bolts unless specifically called for on the assembly drawing.

Bolts and nuts for which torque is not specified should be tightened enough to ensure a firm mating between parts in accordance

with good maintenance practice. Where possible, the use of an air driven impact wrench is recommended for bolts over one

inch (25 mm) in diameter.

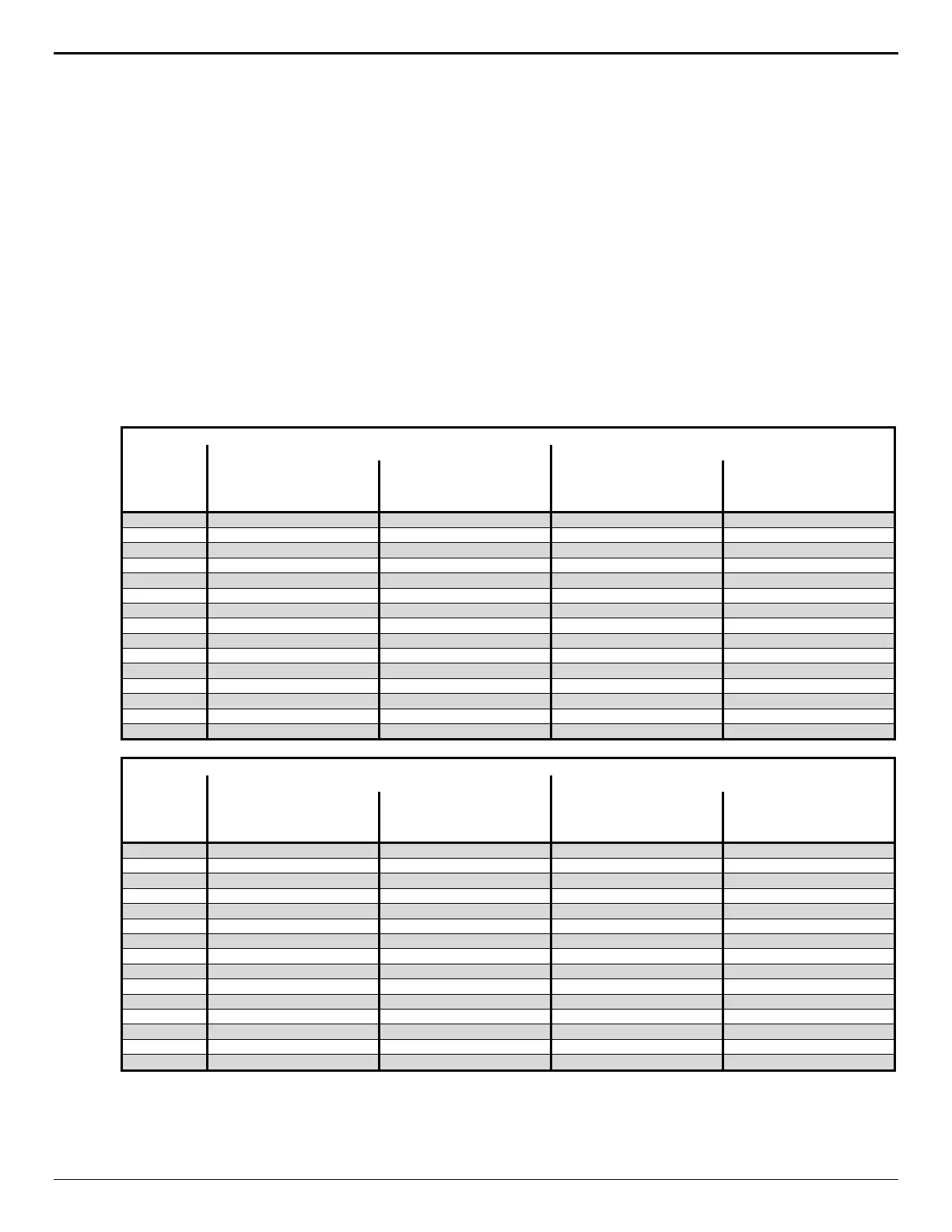

ENGLISH FASTENERS

Size

Anti-Sieze Lubricated / Oiled

Pump Assembly

Fasteners

Mounting Equipment

to Sub Base

Pump Assembly

Fasteners

Mounting Equipment

to Sub Base

ft-lbs N-m ft-lbs N-m ft-lbs N-m ft-lbs N-m

1/4" 3 5 5 6 5 6 7 9

3/8" 12 17 17 23 19 25 25 35

1/2" 30 40 40 55 45 60 60 85

5/8" 60 80 85 115 90 120 125 170

3/4" 105 145 150 200 160 215 220 300

7/8" 175 230 240 325 250 350 360 485

1" 260 350 360 490 385 520 540 730

1 1/8" 320 430 445 600 470 645 660 900

1 1/4" 450 610 620 850 670 910 940 1,275

1 3/8" 590 800 825 1,115 880 1,195 1,225 1,670

1 1/2" 780 1,060 1,090 1,480 1,170 1,585 1,635 2,220

1 3/4" 915 1,240 1,280 1,735 1,370 1,850 1,920 2,600

2" 1,375 1,864 1,925 2,610 2,060 2,795 2,885 3,910

2 1/4" 2,010 2,726 2,815 3,815 3,015 4,085 4,220 5,725

2 1/2" 2,750 3,729 3,850 5,220 4,125 5,590 5,775 7,825

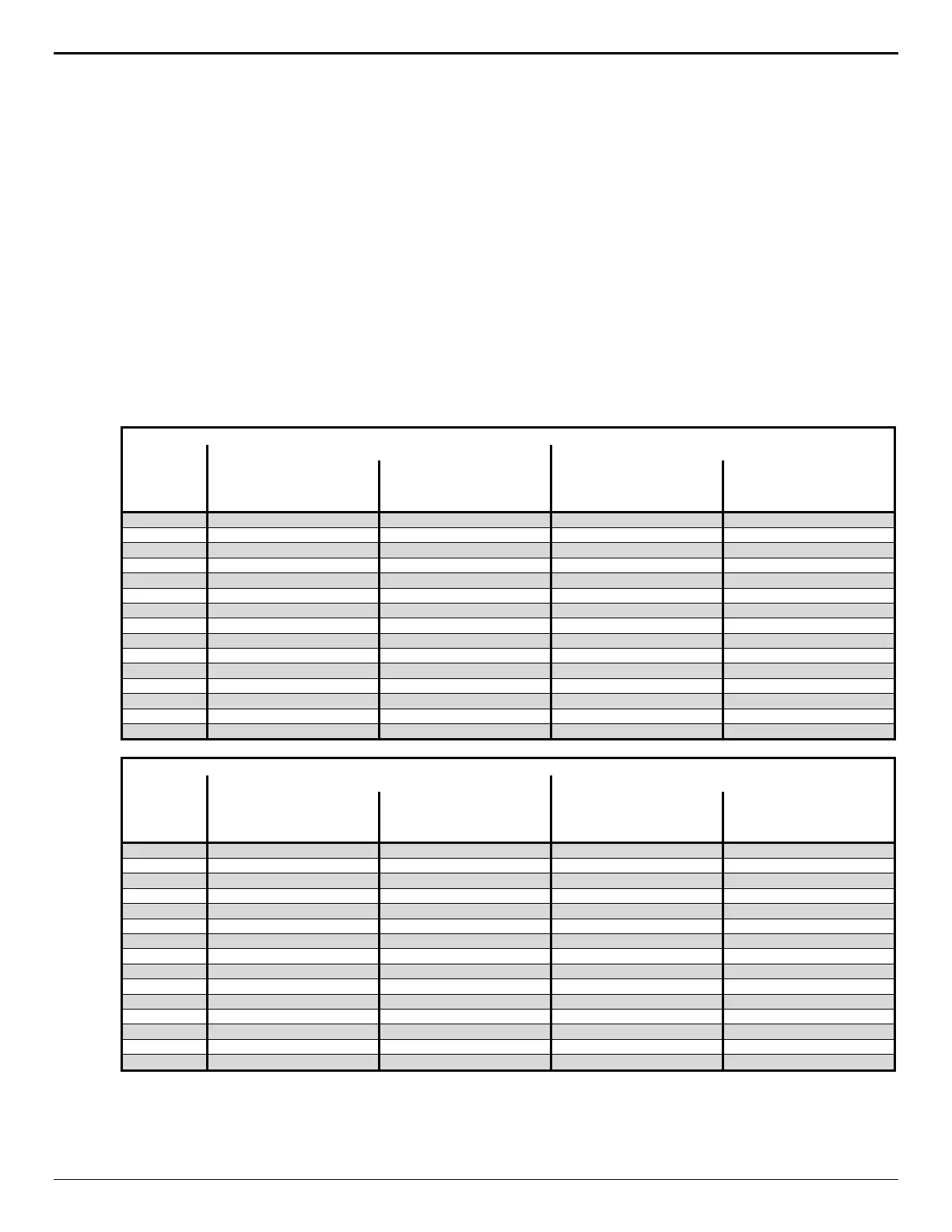

METRIC FASTENERS

Size

Anti-Sieze Lubricated / Oiled

Pump Assembly

Fasteners

Mounting Equipment

to Sub Base

Pump Assembly

Fasteners

Mounting Equipment

to Sub Base

ft-lbs N-m ft-lbs N-m ft-lbs N-m ft-lbs N-m

M8 8 11 10 14 10 15 16 20

M10 15 21 20 28 20 30 30 40

M12 25 35 35 50 40 50 55 75

M16 65 90 90 125 100 130 135 180

M20 130 180 180 250 195 265 270 370

M22 175 250 240 335 260 360 370 500

M24 225 315 305 425 335 450 470 640

M27 325 455 440 615 490 660 680 925

M30 450 625 605 850 670 910 940 1,270

M36 780 1,090 1,060 1,480 1,170 1,600 1,640 2,220

M38 920 1,285 1,250 1,740 1,375 1,865 1,930 2,615

M39 995 1,390 1,350 1,885 1,490 2,020 2,090 2,830

M42 1,245 1,740 1,685 2,360 1,865 2,530 2,610 3,540

M48 1,860 2,610 2,525 3,540 2,795 3,790 3,910 5,300

M64 4,445 6,220 6,025 8,440 6,670 9,040 9,335 12,650

Values based on Grade 5 fasteners

Torque Values taken at 50% Proof Strength for Pump Assembly Fasteners

70% Proof Strength for Mounting Equipment to Sub Base

K-Factors = 0.120 for Anti Sieze

0.180 for Lubricated / Oiled

Loading...

Loading...