ENGINE

SM-E4B SERIES, WSM

1-S52

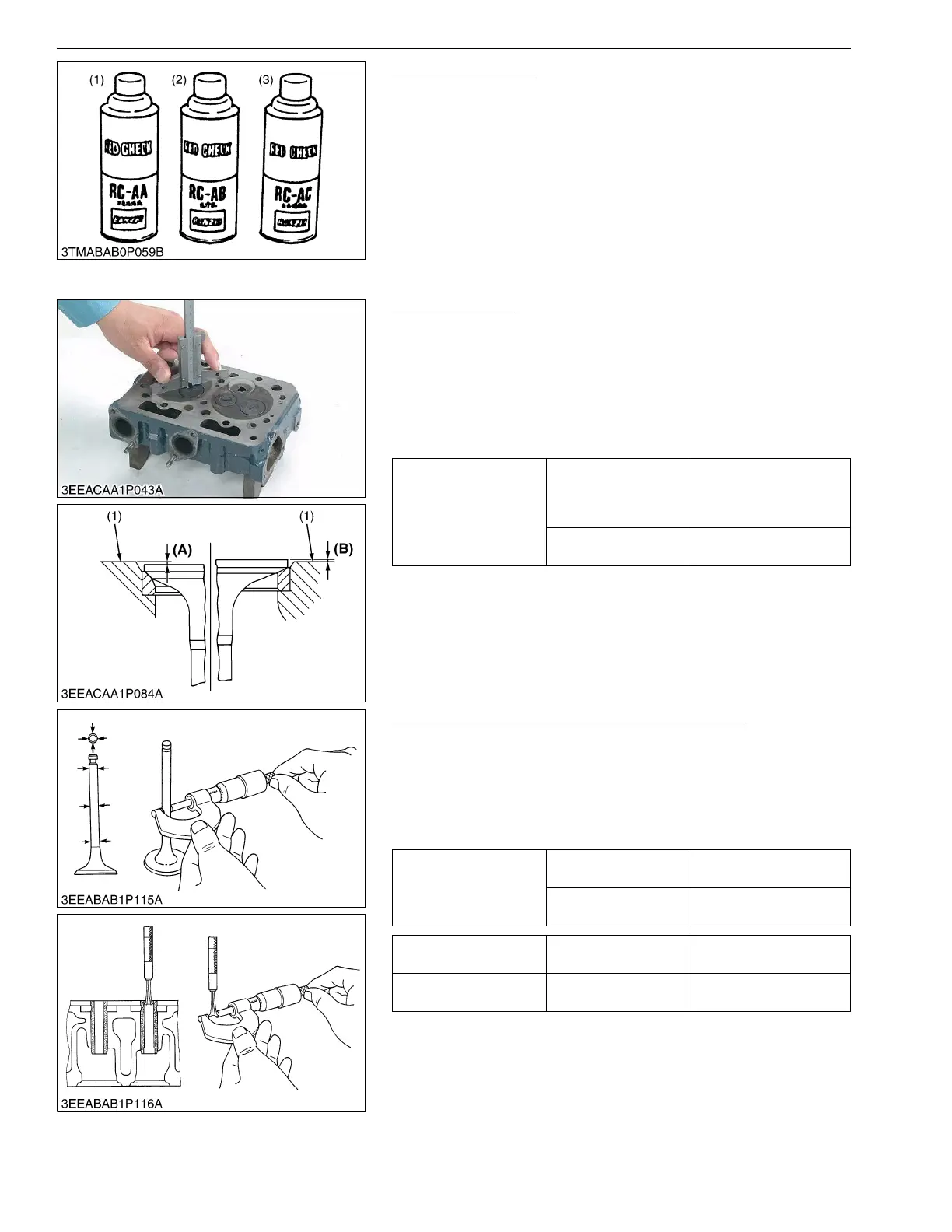

Cylinder Head Flaw

1. Prepare an air spray red check.

2. Clean the surface of the cylinder head with detergent (2).

3. Spray the cylinder head surface with the red permeative liquid

(1). Leave it five to ten minutes after spraying.

4. Wash away the read permeative liquid on the cylinder head

surface with the detergent (2).

5. Spray the cylinder head surface with white developer (3).

6. If flawed, it can be identified as red marks.

9Y1210785ENS0063US0

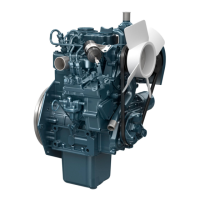

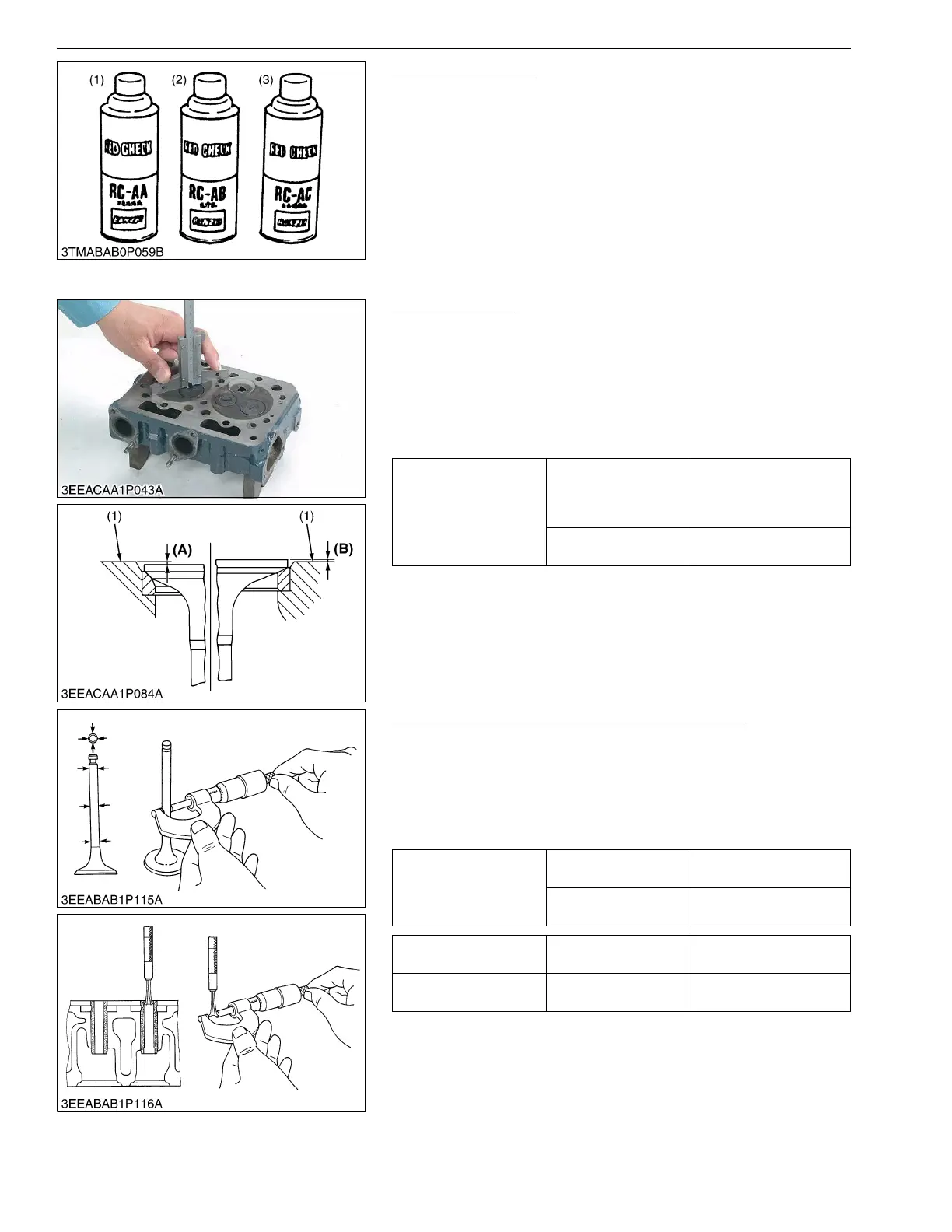

Valve Recessing

1. Clean the cylinder head surface, valve face and valve seat.

2. Insert the valve into the valve guide.

3. Measure the valve recessing with a depth gauge.

4. If the measurement exceeds the allowable limit, replace the

valve.

5. If it still exceeds the allowable limit after replacing the valve,

replace the cylinder head.

9Y1210785ENS0064US0

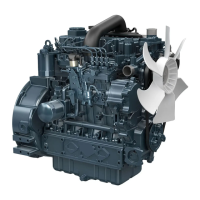

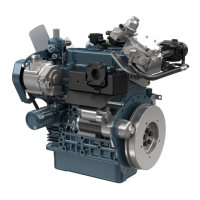

Clearance between Valve Stem and Valve Guide

1. Remove carbon from the valve guide section.

2. Measure the valve stem O.D. with an outside micrometer.

3. Measure the valve guide I.D. with a small hole gauge, and

calculate the clearance.

4. If the clearance exceeds the allowable limit, replace the valves.

If it still exceeds the allowable limit, replace the valve guide.

9Y1210785ENS0065US0

(1) Red Permeative Liquid

(2) Detergent

(3) White Developer

Valve recessing

(Intake and exhaust)

Factory specification

−0.10 (protrusion) to 0.10

(recessing) mm

−0.0039 (protrusion) to

0.0039 (recessing) in.

Allowable limit

0.30 (recessing) mm

0.012 (recessing) in.

(1) Cylinder Head Surface (A) Recessing

(B) Protrusion

Clearance between

valve stem and valve

guide

Factory specification

0.030 to 0.057 mm

0.0012 to 0.0022 in.

Allowable limit

0.10 mm

0.0039 in.

Valve stem O.D. Factory specification

5.968 to 5.980 mm

0.2350 to 0.2354 in.

Valve guide I.D. Factory specification

6.010 to 6.025 mm

0.2367 to 0.2372 in.

Loading...

Loading...