ENGINE

SM-E4B SERIES, WSM

1-S61

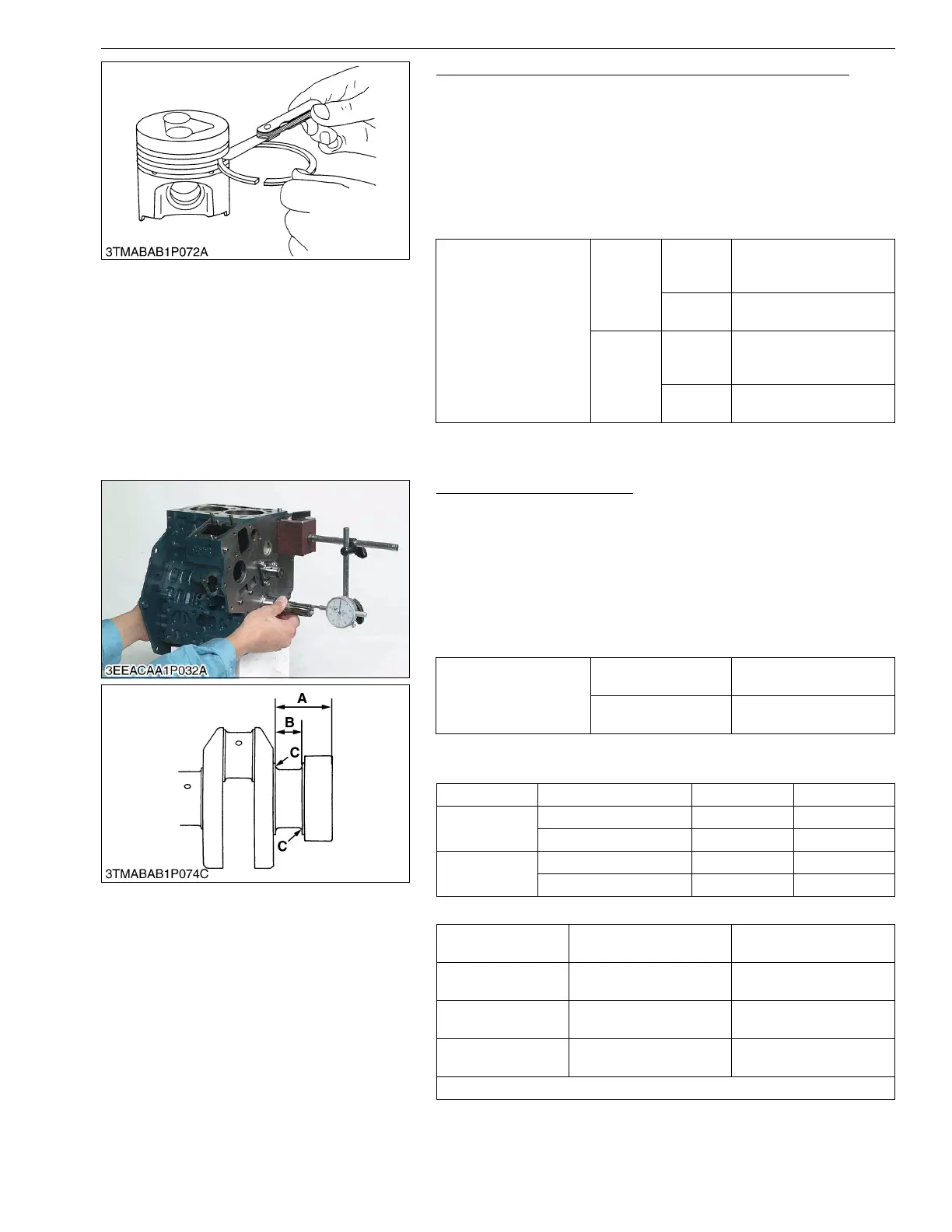

Clearance between Piston Ring and Piston Ring Groove

1. Clean the rings and the ring grooves, and install each ring in its

groove.

2. Measure the clearance between the ring and the groove with a

feeler gauge.

3. If the clearance exceeds the allowable limit, replace the piston

ring.

4. If the clearance still exceeds the allowable limit after replacing

the ring, replace the piston.

9Y1210785ENS0088US0

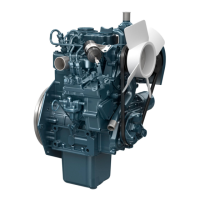

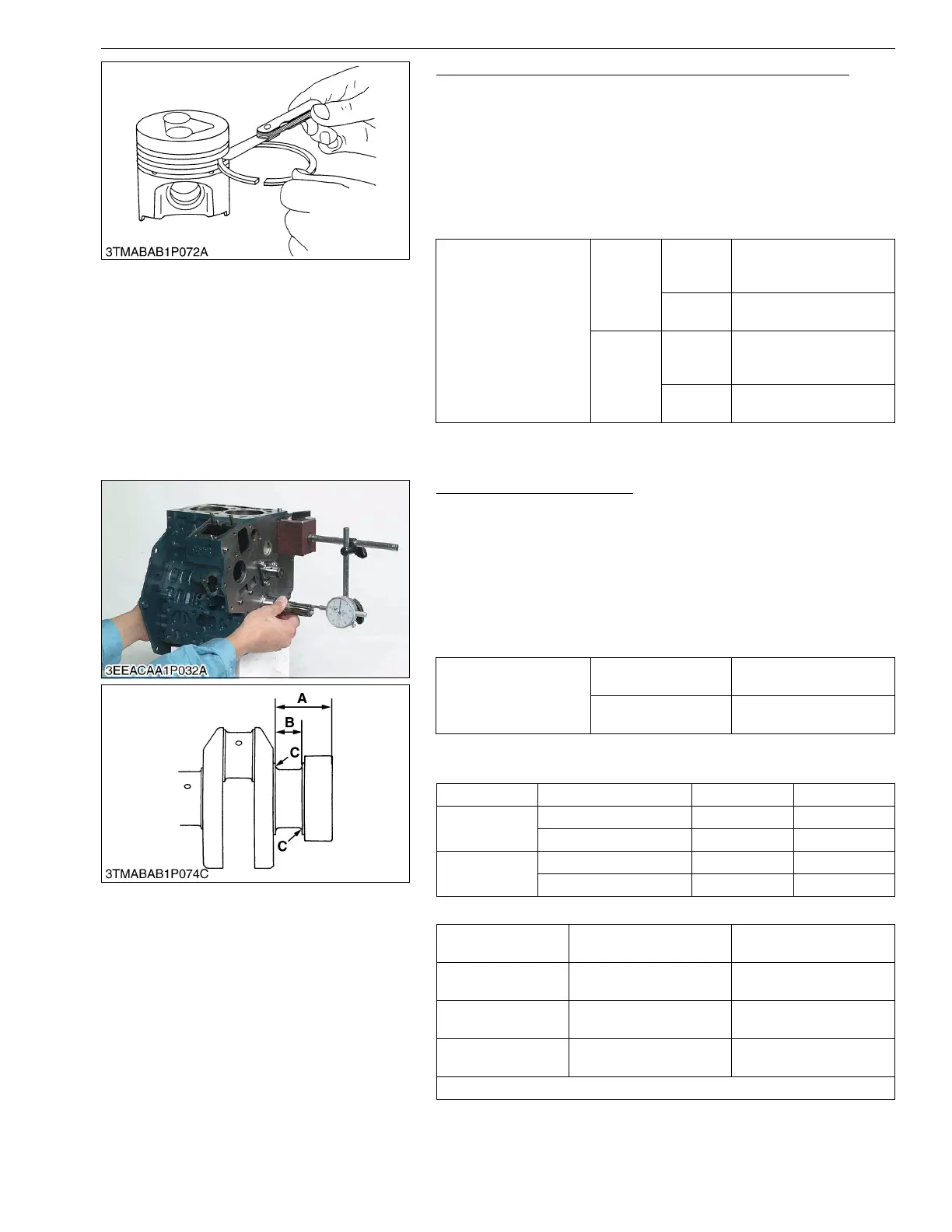

(4) Crankshaft

Crankshaft Side Clearance

1. Set a dial indicator with its tip on the end of the crankshaft.

2. Measure the side clearance by moving the crankshaft to the

front and rear.

3. If the measurement exceeds the allowable limit, replace the

thrust bearings.

4. If the same size bearing is useless because of the crankshaft

journal wear, replace it with an oversize one referring to the

table and figure.

(Reference)

• Oversize thrust bearing

• Oversize dimensions of crankshaft journal

9Y1210785ENS0089US0

Clearance between

piston ring and piston

ring groove

Second

ring

Factory

specifica-

tion

0.0900 to 0.120 mm

0.00355 to 0.00472 in.

Allowable

limit

0.15 mm

0.0059 in.

Oil ring

Factory

specifica-

tion

0.040 to 0.080 mm

0.0016 to 0.0031 in.

Allowable

limit

0.15 mm

0.0059 in.

Crankshaft side

clearance

Factory specification

0.15 to 0.31 mm

0.0059 to 0.012 in.

Allowable limit

0.50 mm

0.020 in.

Oversize Bearing Code Number Marking

0.20 mm

0.0079 in.

Thrust bearing 1 02 15261-23950 020 OS

Thrust bearing 2 02 15261-23970 020 OS

0.40 mm

0.016 in.

Thrust bearing 1 04 15261-23960 040 OS

Thrust bearing 2 04 15261-23980 040 OS

Oversize

0.20 mm

0.0079 in.

0.40 mm

0.016 in.

Dimension A

46.10 to 46.30 mm

1.815 to 1.822 in.

46.30 to 46.50 mm

1.823 to 1.830 in.

Dimension B

23.40 to 23.45 mm

0.9213 to 0.9232 in.

23.80 to 23.85 mm

0.9370 to 0.9389 in.

Dimension C

1.8 to 2.2 mm radius

0.071 to 0.086 in. radius

1.8 to 2.2 mm radius

0.071 to 0.086 in. radius

The crankshaft journal must be fine-finished to higher than Rmax. = 0.8S

Loading...

Loading...