ENGINE

SM-E4B SERIES, WSM

1-S60

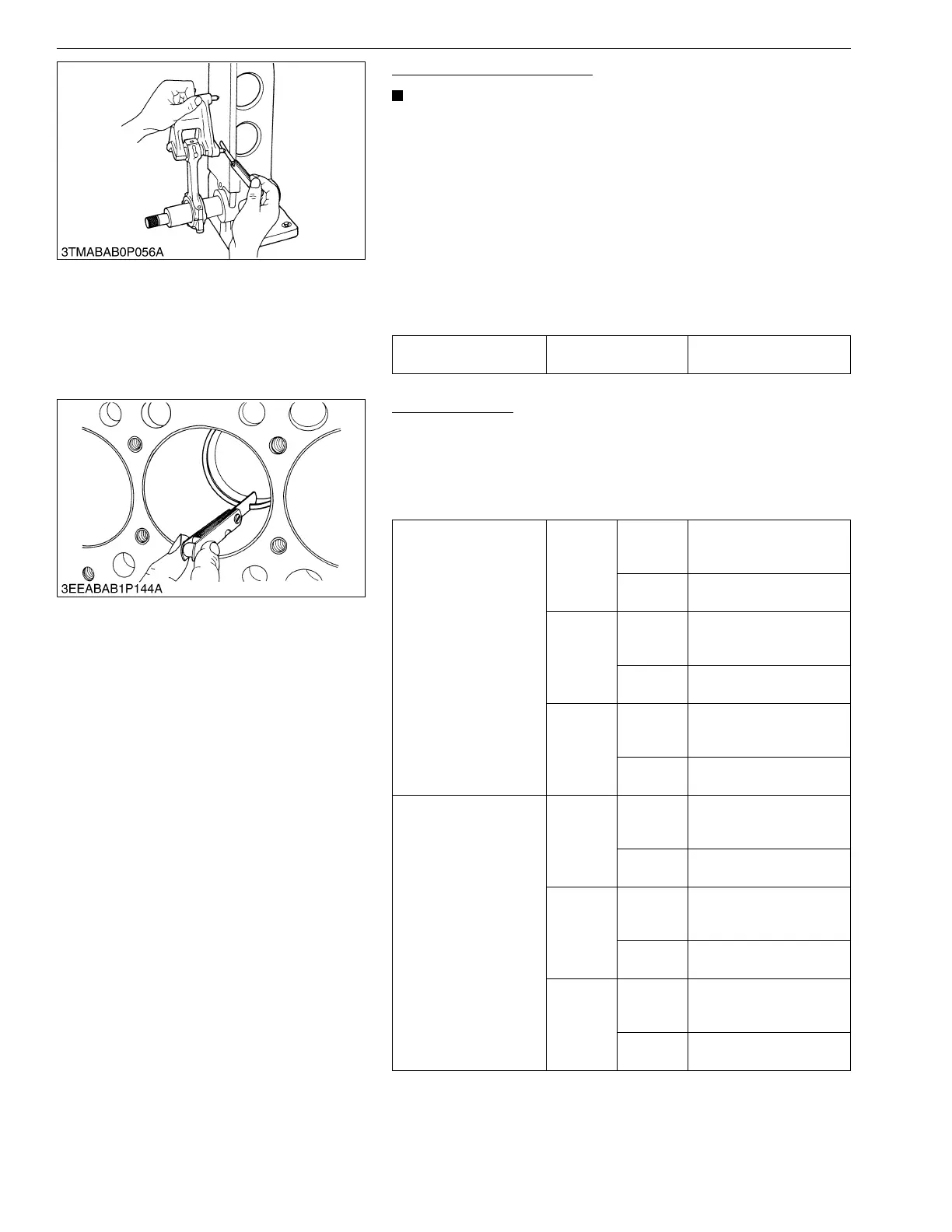

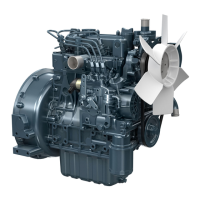

Connecting Rod Alignment

• Since the I.D. of the connecting rod small end bushing is

the basis of this check, check bushing for wear

beforehand.

1. Install the piston pin into the connecting rod.

2. Install the connecting rod on the connecting rod alignment tool.

3. Put a gauge over the piston pin, and move it against the face

plate.

4. If the gauge does not fit squarely against the face plate,

measure the space between the pin of the gauge and the face

plate.

5. If the measurement exceeds the allowable limit, replace the

connecting rod.

9Y1210785ENS0086US0

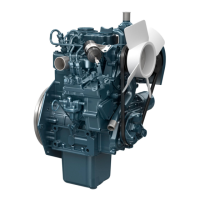

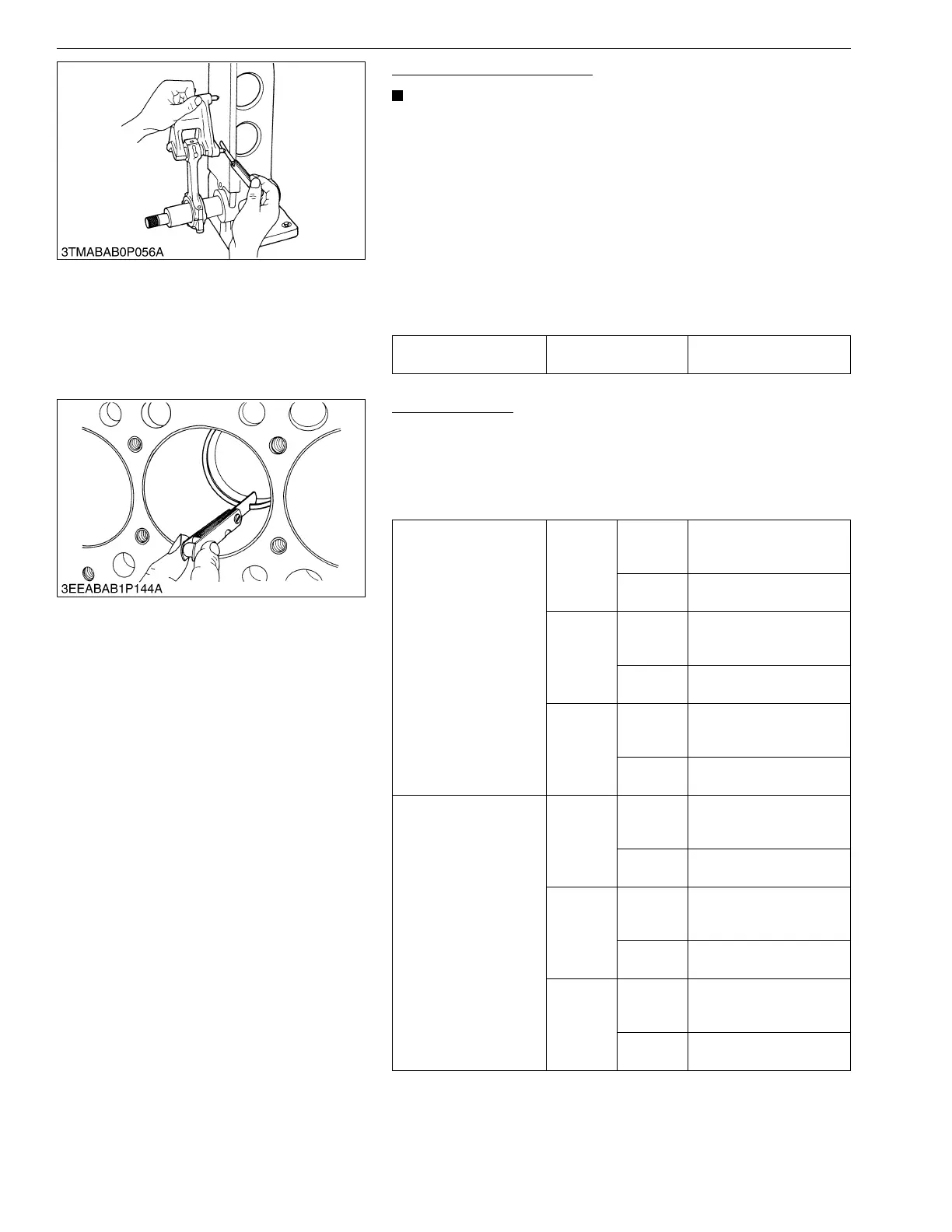

Piston Ring Gap

1. Insert the piston ring into the lower part of the cylinder (the least

worn out part) with a piston ring compressor and piston.

2. Measure the ring gap with a feeler gauge.

3. If the measurement exceeds the allowable limit, replace the

piston ring.

9Y1210785ENS0087US0

Connecting rod

alignment

Allowable limit

0.05 mm

0.002 in.

Piston ring gap

[Z482-E4B]

[D722-E4B]

[D782-E4B]

Top ring

Factory

specifica-

tion

0.12 to 0.27 mm

0.0047 to 0.010 in.

Allowable

limit

1.15 mm

0.0453 in.

Second

ring

Factory

specifica-

tion

0.30 to 0.45 mm

0.012 to 0.017 in.

Allowable

limit

1.20 mm

0.0472 in.

Oil ring

Factory

specifica-

tion

0.15 to 0.35 mm

0.0059 to 0.013 in.

Allowable

limit

1.20 mm

0.0472 in.

Piston ring gap

[Z602-E4B]

[D902-E4B]

Top ring

Factory

specifica-

tion

0.15 to 0.30 mm

0.0059 to 0.011 in.

Allowable

limit

1.25 mm

0.0472 in.

Second

ring

Factory

specifica-

tion

0.35 to 0.50 mm

0.014 to 0.019 in.

Allowable

limit

1.25 mm

0.0492 in.

Oil ring

Factory

specifica-

tion

0.15 to 0.35 mm

0.0059 to 0.013 in.

Allowable

limit

1.20 mm

0.0472 in.

Loading...

Loading...