MSD Legend Series Operation & Maintenance Manual | 23

HYDRAULIC INSPECTION

1.

Wear personal protection equipment at all times. This

includes eye protection, hard hat, steel toe shoes,

leather gloves and hearing protection.

Trapped hydraulic pressure may be present after the

taken when removing hydraulic hoses or lines. Injury or

death could result.

Locate at, hard ground and place the attachment on the ground.

2. Check the hydraulic oil reservoir and ensure it is lled.

3. Visually inspect all hydraulic hoses and lines for leaks or damage.

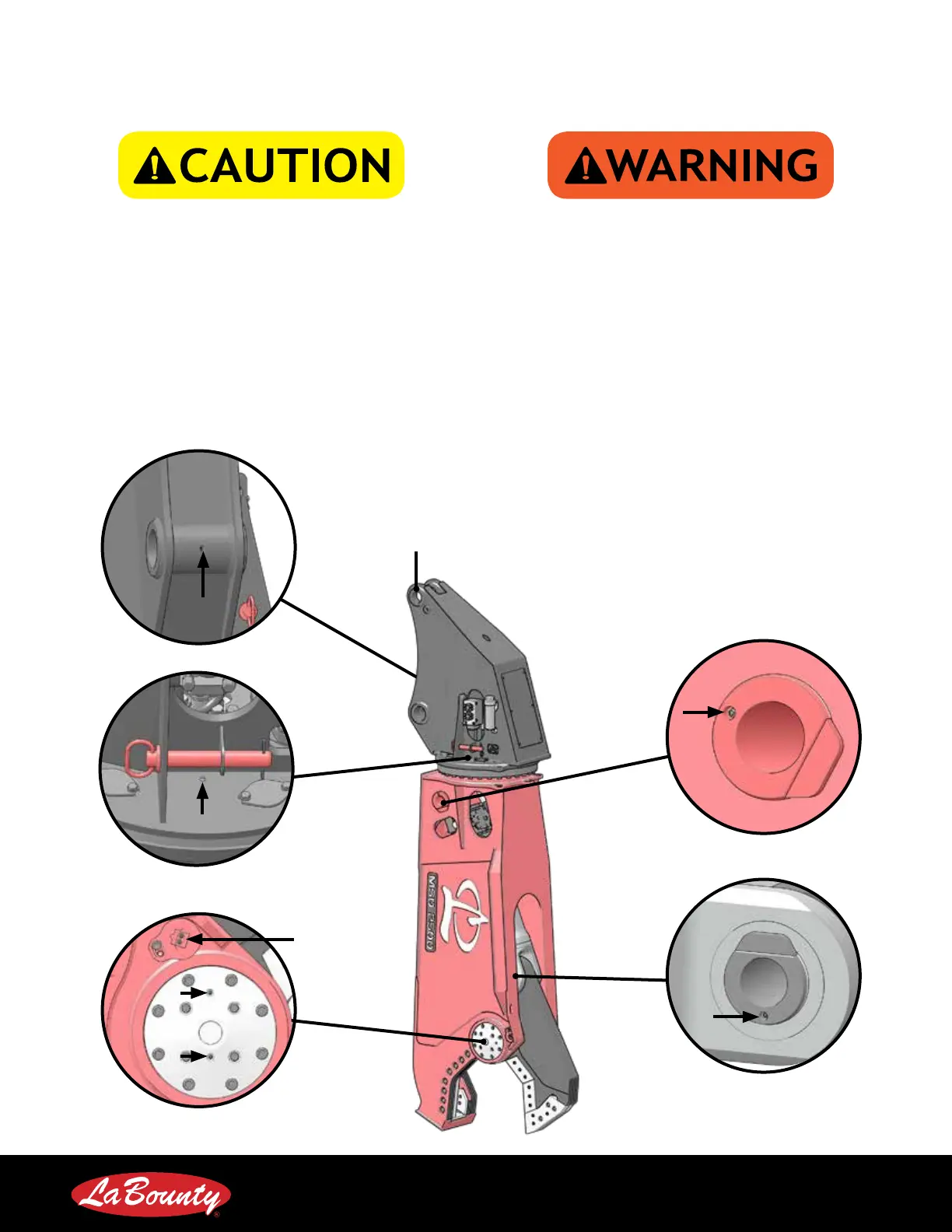

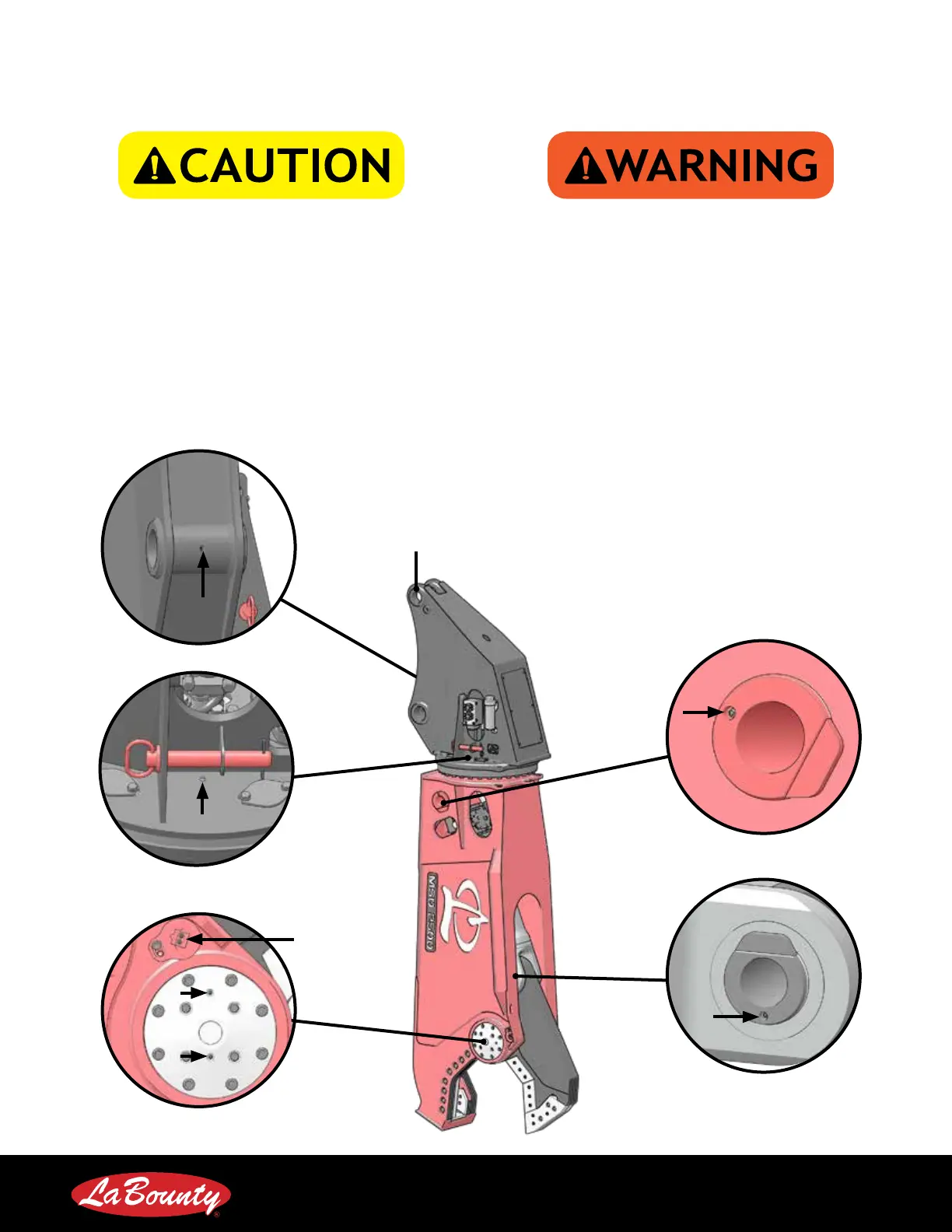

SHEAR LUBRICATION

Use premium grease, No. 2EP. Grease ttings are shown with yellow “GREASE” decals. Each grease tting

requires .3 oz (8 g) of grease every 8 hours. This is about 6 shots of grease from an average grease gun.

Note: Follow all OEM lubrication instructions as it pertains to the cylinder and stick / boom connections.

CONNECTION

Lubrication Locations

FIGURE 17

TURNTABLE BEARING

MAIN PIVOT GROUP AND SLIDE SCREW

SLIDE SCREW

Loading...

Loading...