40 | MSD Legend Series Operation & Maintenance Manual

• When grinding or sanding, wear an approved respirator.

• Remove solvent, paint strippers and other ammable material from the area before hardsurfacing.

• Have a re extinguisher nearby.

• Do all work in a well ventilated area.

• Disconnect the excavator battery before welding.

Hardsurface Instructions

Build-up

1. Disconnect InSite power cable before welding.

2. Using AWS E7018 welding rod, make side by side underlayment beads.

3. Relieve stress and remove slag after each pass by peening vigorously with an air operated slag peener.

Note: Check the temperature often. Maintain 300° - 400° F (149° - 205° C) during build-up.

Hardsurface

4. Apply a bead of Amalloy 814H rod directly on top of each underlayment bead.

Note: Do not apply more than two layers of hard surfacing.

5. Relieve stress and remove slag after each pass by peening vigorously with an air operated slag peener.

6. Taper the ends of each bead by grinding. Do not undercut the weld.

7. When grinding is complete, peen the area until it is shiny or until the peener cannot dent the weld, about 5-10

minutes.

8. If the temperature has dropped below 400°F (205° C) within 6 inches of the welded area, heat the area up to 400° F

(205° C).

9. Wrap the welded area with a heat blanket and allow to cool slowly.

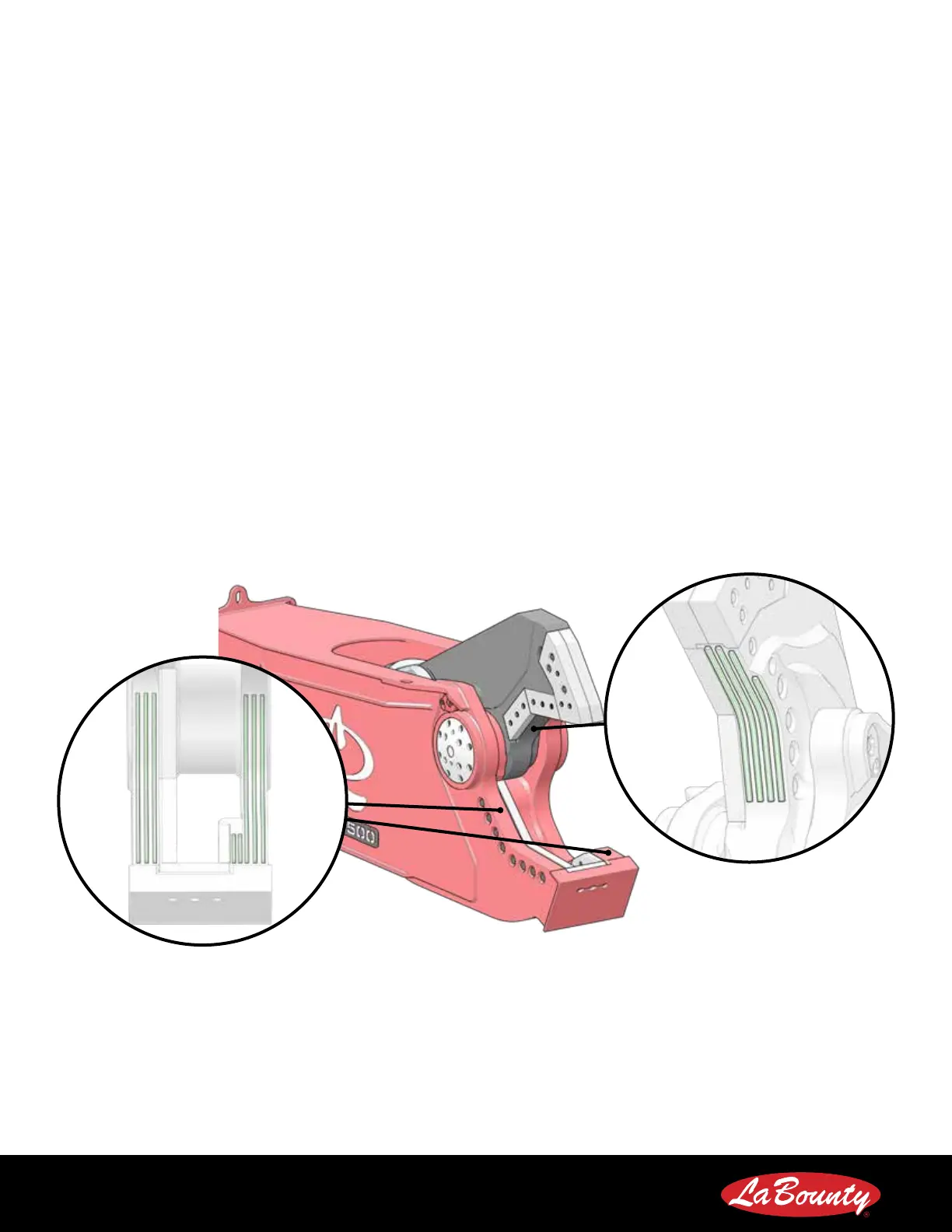

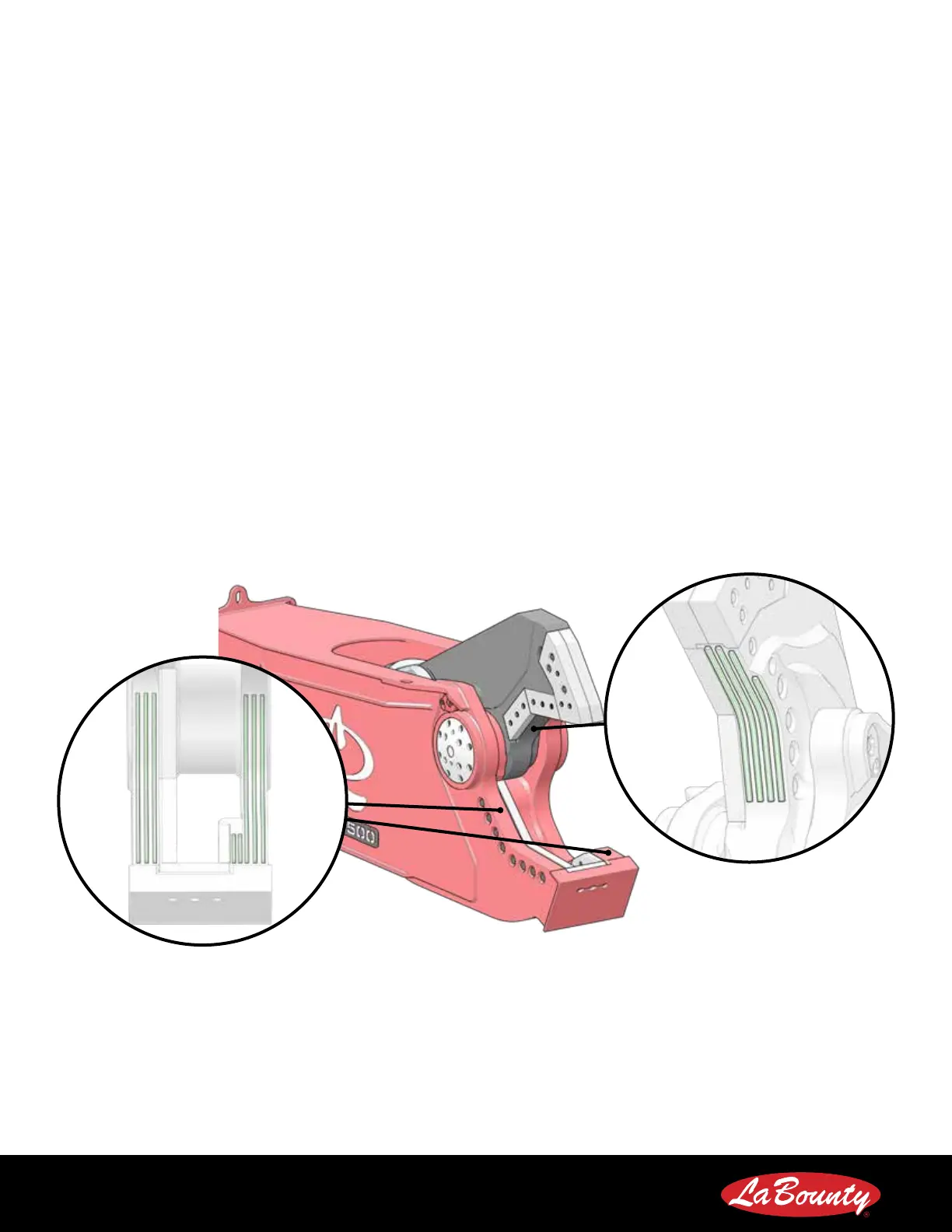

Build Up & Grain Direction

FIGURE 33

Loading...

Loading...