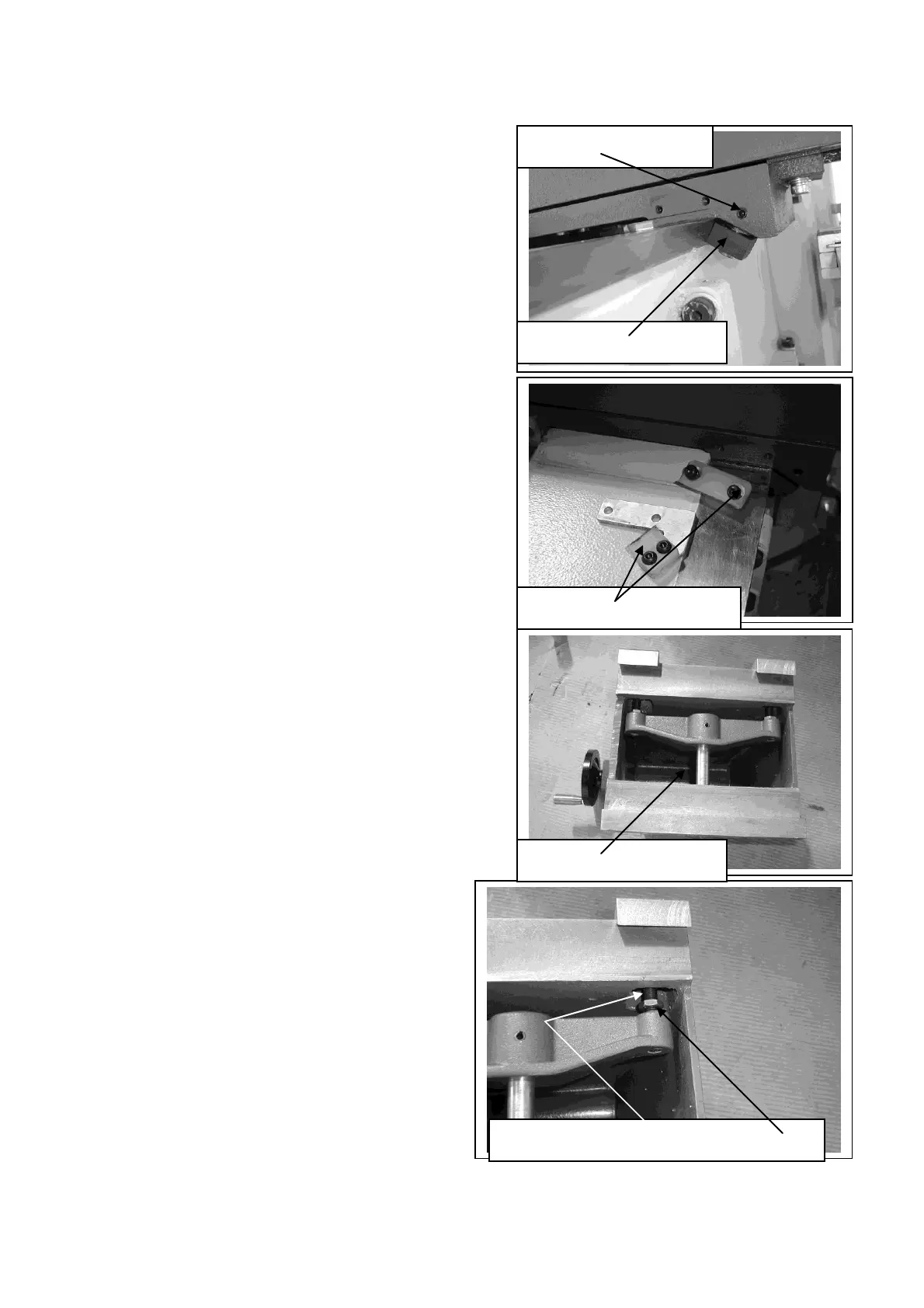

Copy saddle “V” guide adjustment.

Blocks that are on eccentric cams control the

clearance between the bed and the copy saddle.

By loosening the shaft clamping screw and

rotating the eccentric the clearance is adjusted.

It is not recommended that the adjustment be

changed unless excessive ware has taken place.

If adjustment is required loosen the clamp screw

and rotate the shaft with an allen key until there

is a snug fit between the bed and the copy

saddle. The copy saddle should move smoothly

with out excessive side ways movement.

Copy saddle bed wipers.

The copy saddle is provided with nylon wipers

that assist in removing any dirt that is on the bed

of the lathe when the copy saddle moves along

the bed. The pads will need to be removed,

cleaned and readjusted periodically. When

refitting the wipers ensure a snug fit between the

wiper and the bed. They should not be too tight

on the bed, as this will cause excessive ware to

the wipers.

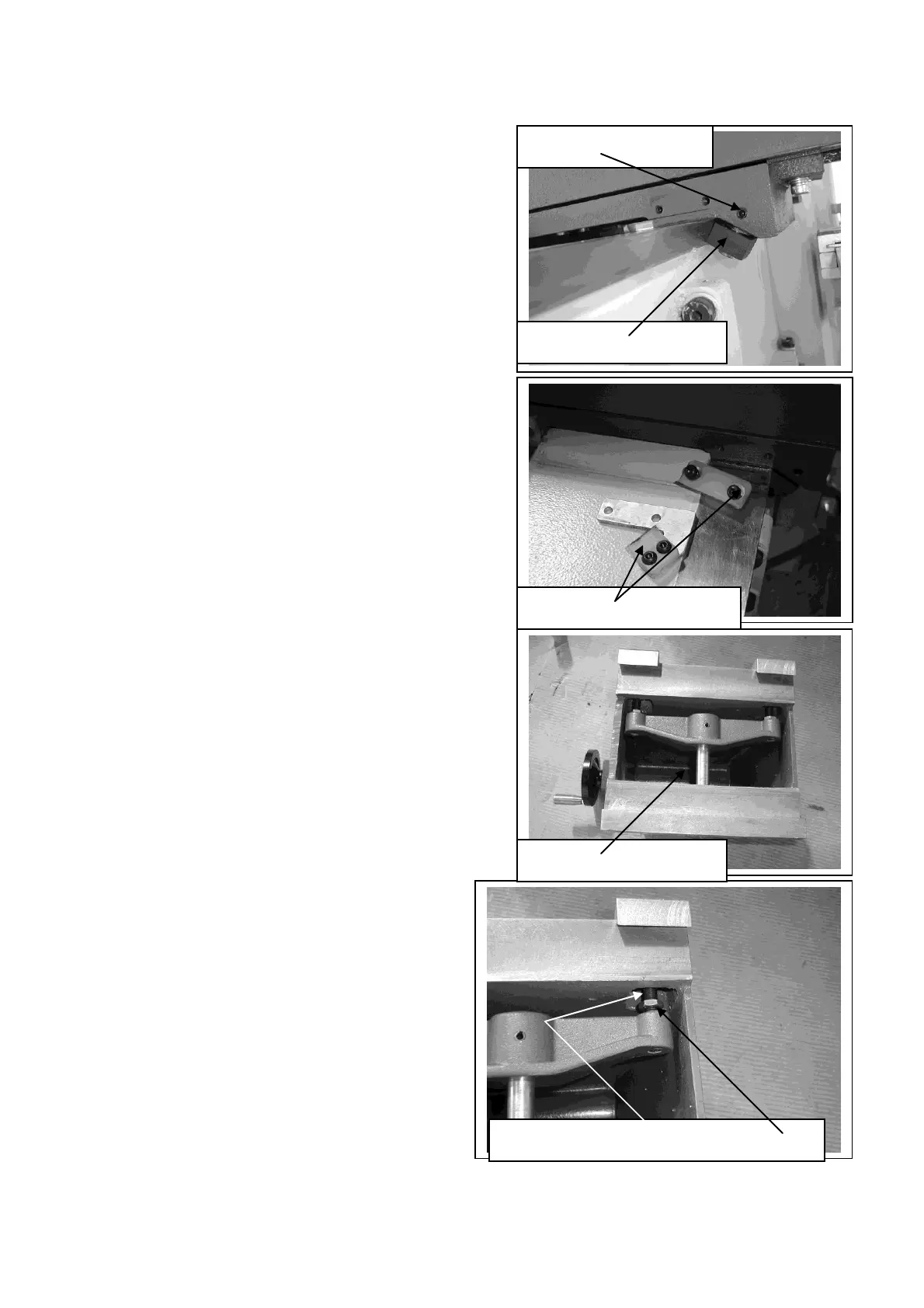

Tailstock “V” guide adjustment.

“V” blocks that are on screw threads can be

adjusted to change the position that the

clamping handle rests in when in the clamped

position. To adjust the tailstock to bed

loosen the locknut, rotate the screw and re

clamp the locknut. Note It is important

that both screws are rotated the same

amount. If the screws are moved different

amounts the adjustable “V” blocks will

not function correctly.

Tailstock adjusting screw and lock nut

Loading...

Loading...