A3

A2

A2

A1

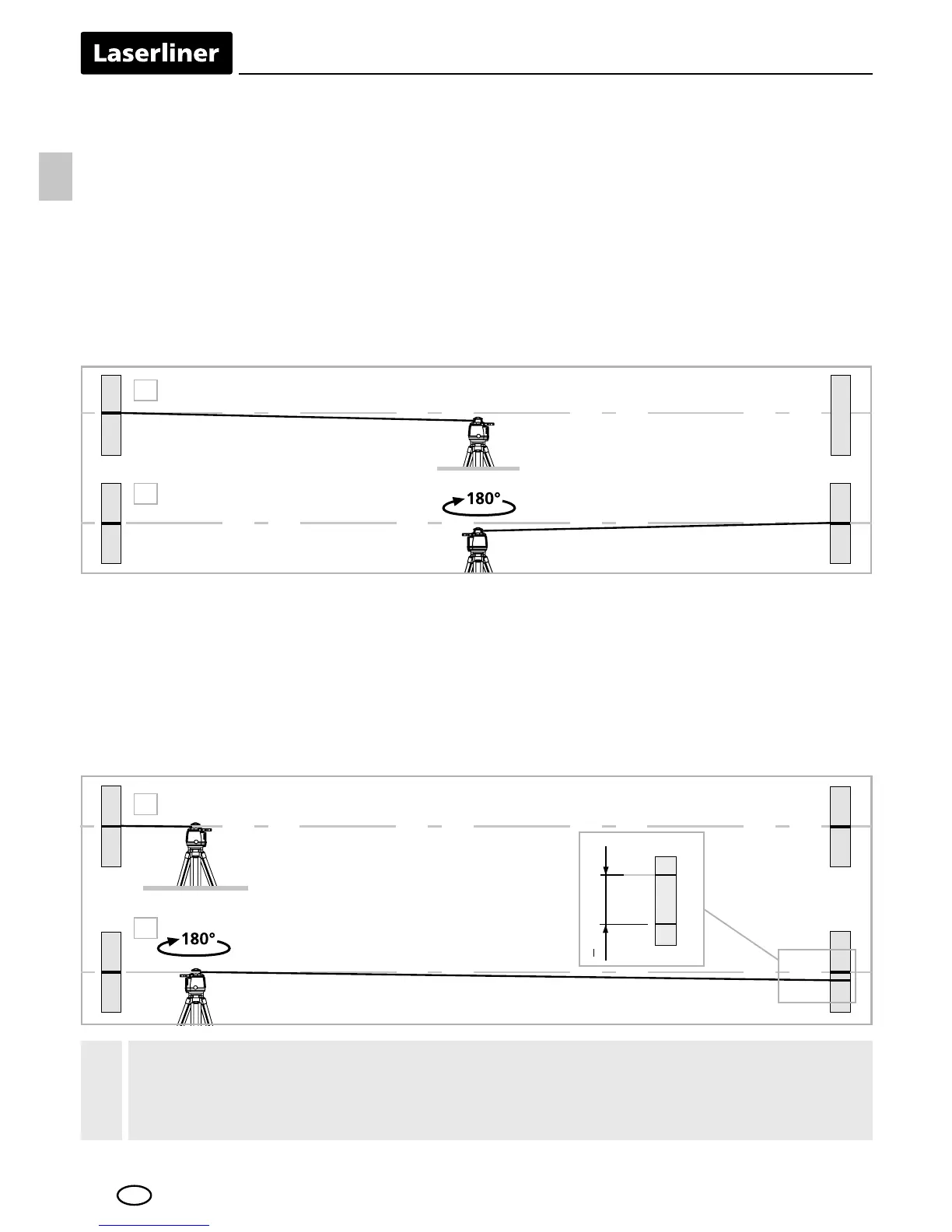

4.

3.

A3

A2

<

0,15 mm / m = OK

EN

If points A2 and A3 are more than 0.15 mm / m apart on either

the X or Y axis, the device is in need of adjustment. Contact your

authorised dealer or else the UMAREX-LASERLINER Service Department.

!

Performing the calibration check

3. Position the device as near as possible to the wall at the height of point

A1. Now adjust the device in the X axis.

4. Turn the device through 180° and mark point A3. The difference between

points A2 and A3 is the tolerance for the X axis.

5. To check the Y and Z axis, repeat steps 3 and 4.

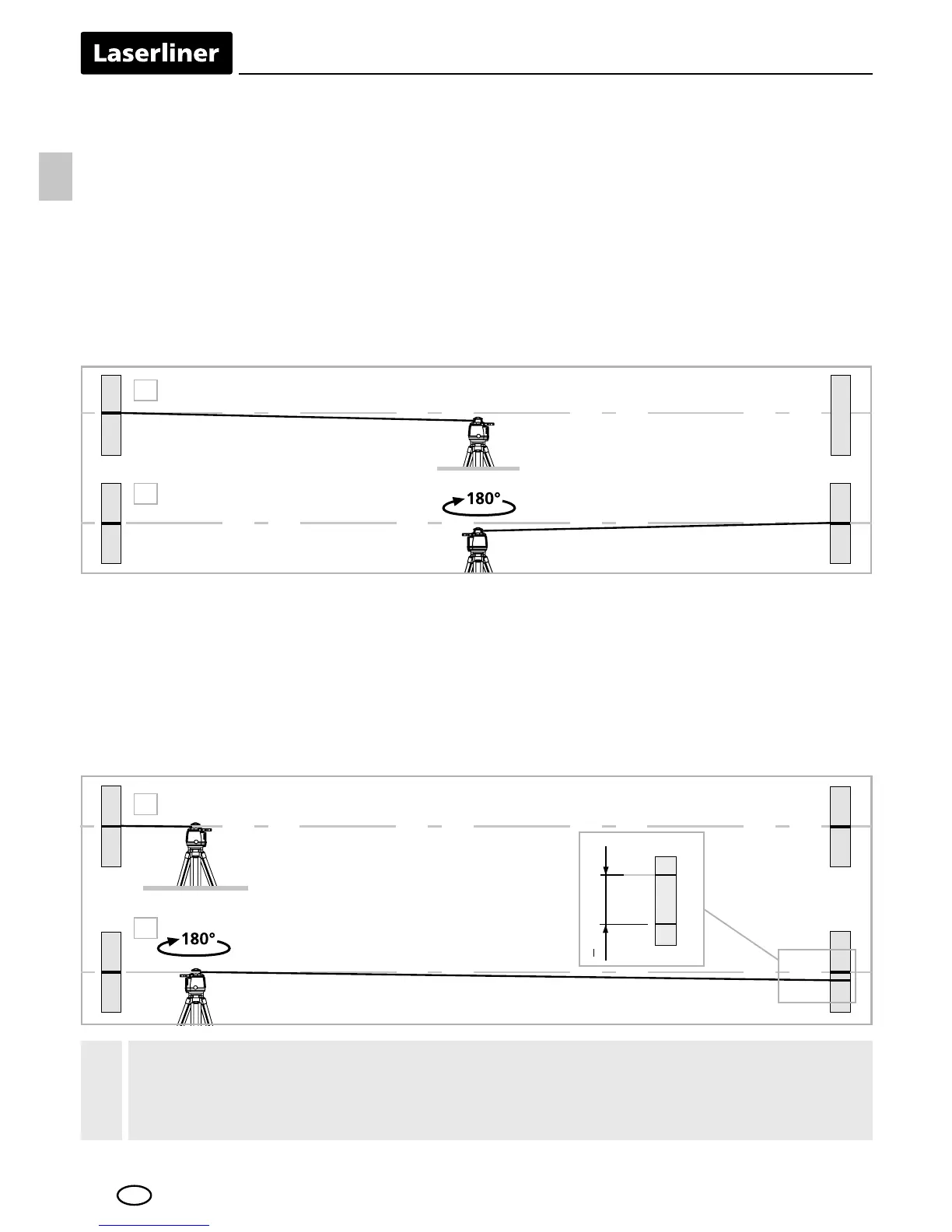

Preparing the calibration check

It is possible for you to check the calibration of the laser. To do this, position

the device midway between 2 walls, which must be at least 5 metres apart.

Switch the device on. The best calibration results are achieved if the device

is mounted on a tripod. IMPORTANT: The automatic sensor must be active

(auto/slope LED is off).

1. Mark point A1 on the wall.

2. Turn the device through 180° and mark point A2. You now have a

horizontal reference between points A1 and A2.

Loading...

Loading...