(T9) ENTER key: Pressing this key when a LED corresponding to an operation is lit but not

flashing will permit modifying the times and the fluid quantities. Upon completion of

modification, press the key again to confirm the datum

(T10) START key: Pressing this key will start the operation indicated by the lighted LED

(T11) STOP key: Pressing this key will stop the operation indicated by the flashing LED.

(T12) TEMPERATURE key: Pressing this key the display will show the bottle temperature in

Celsius degree and Fahrenheit degree.

(T13) Display: According to the operation selected, displays the time or refrigerant quantity

values.

STATUS AND ALARM PANEL

See fig 10:

(C1) HEATER ON: Lights to indicate that the electrical resistance of the machine is heating

the bottle to maintain fluid pressure between 5.5 and 8,5 bar. The resistance does not operate

during the RECOVERY phase of operation

(C2) HIGH PRESSURE: Lights and emits an acoustic signal when the pressure of the fluid in

the circuit catch up 17.5 bar. The RECOVERY operation is automatically interrupted.

(C3) FULL BOTTLE: Lights and emits an acoustic signal when the bottle is full to more than

80% capacity (that is, 10 kg). The Recovery operation is automatically interrupted.

(C4) EMPTY BOTTLE: Lights and emits an acoustic signal when the quantity of refrigerant

fluid contained in the bottle is low (2 kg). in order to avoid the emission of non-condensable

gases. Fill the bottle according to the procedure described in the ROUTINE MAINTENANCE

section.

PRELIMINARY OPERATIONS

Check that switch (j) is set to position 0. Check that all the machine taps are closed. Connect the

machine to the electrical supply and switch on. Check that the vacuum pump oil level indicator shows at

least one-half full. If the level is lower, add oil as explained in the MAINTENANCE section. Check that in

the top-up oil container (e) there are at least 100 cc of the oil recommended by the manufacturer of the

vehicle A/C system. Check the level of the oil in container (m) (< 200 cc). Check on the machine display

that there are at least 3 kg of refrigerant in the bottle. Should this not be the case, fill the machine bottle

from an external bottle of appropriate refrigerant following the procedure described in the ROUTINE

MAINTENANCE section.

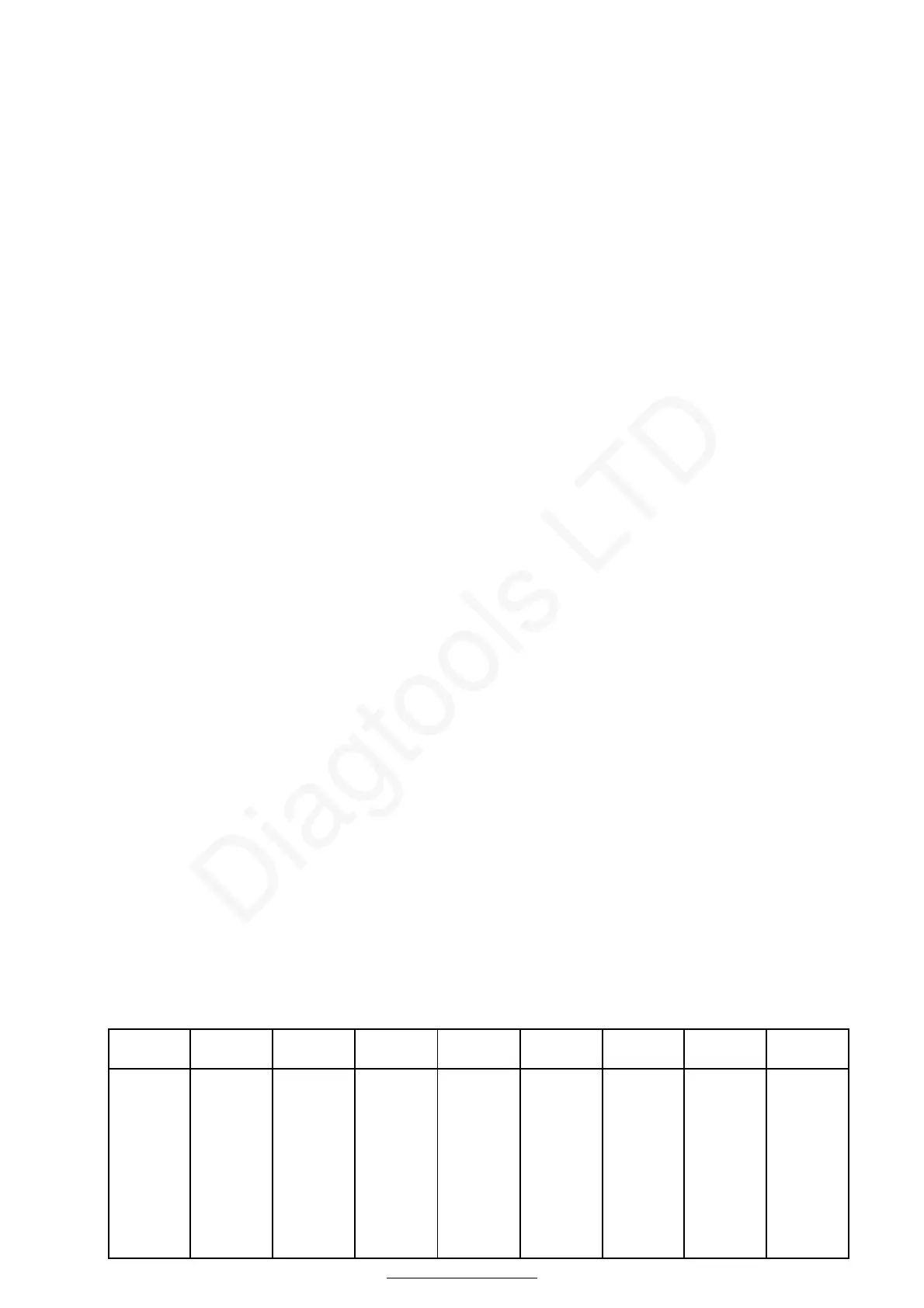

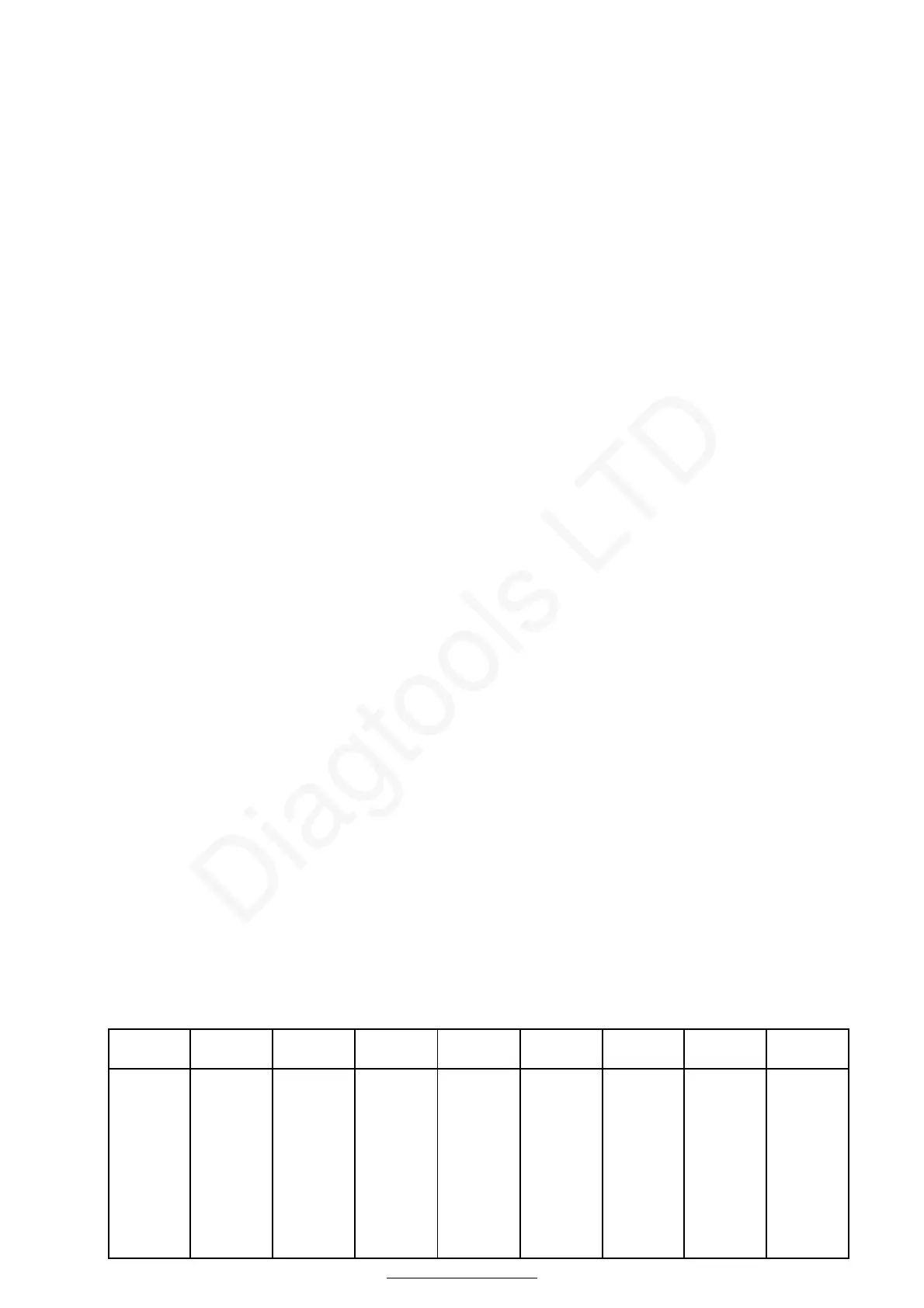

PURGE NON CONDENSABLE GAS

Before every service, check if there is air into the bottle; press the temperature bottle key (ref

.12 fig.9) and read the temperature of the bottle. Compare the bottle pressure with the one into

the table; if the bottle pressure if higher of the pressure read on the table, pull the ring of the

security valve and bring back the bottle pressure to the table values. Example: Bottle

temperature = 20 °C, the bottle pressure must bring back at 5,2 bar.

T

(°C)

P

(bar)

T

(°C)

P

(bar)

T

(°C)

P

(bar)

T

(°C)

P

(bar)

T

(°C)

P

(bar)

T

(°C)

P

(bar)

T

(°C)

P

(bar)

T

(°C)

P

(bar)

T

(°C)

P

(bar)

10 3,6 15 4,4 20 5,2 25 6,1 30 7,2 35 8,3 40 9,6 45 11 50 12,6

10,5

3,7 15,5

4,4 20,5

5,3 25,5

6,2 30,5

7,3 35,5

8,4 40,5

9,7 45,5

11,2

50,5

12,8

11 3,8 16 4,5 21 5,4 26 6,3 31 7,4 36 8,6 41 9,9 46 11,3

51 12,9

11,5

3,8 16,5

4,6 21,5

5,5 26,5

6,4 31,5

7,5 36,5

8,7 41,5

10 46,5

11,5

51,5

13,1

12 3,9 17 4,7 22 5,6 27 6,5 32 7,6 37 8,8 42 10,2

47 11,6

52 13,3

12,5

4 17,5

4,8 22,5

5,6 27,5

6,6 32,5

7,7 37,5

8,9 42,5

10,3

47,5

11,8

52,5

13,4

13 4,1 18 4,9 23 5,7 28 6,7 33 7,8 38 9,1 43 10,4

48 12 53 13,6

13,5

4,1 18,5

4,9 23,5

5,8 28,5

6,8 33,5

8 38,5

9,2 43,5

10,6

48,5

12,1

53,5

13,8

14 4,2 19 5 24 5,9 29 6,9 34 8,1 39 9,3 44 10,7

49 12,3

54 14

14,5

4,3 19,5

5,1 24,5

6 29,5

7,1 34,5

8,2 39,5

9,5 44,5

10,9

49,5

12,4

54,5

14,2

www.diagtoools.lv

Diagtools LTD

Loading...

Loading...