Voltage vector sinusoidal PWM control

(V/F control)

Switching frequency : 800~16kHz

Analogue Command: 0.06Hz / 60Hz

150% of rated output current for 1

minute

Start/Stop Braking Time:

0

Saving mode (automatic

adjusting V/F pattern according to the

load condition)

Square of 1.5, 1/7 and 2 curves.

V/F pattern (2 V/F points)

Output voltage adjustment of V/F

pattern

(Variable voltage adjustment of V/F

pattern for acceleration and

deceleration).

Automatic operation for energy

Automatic torque compensation

Automatic adjustment for output voltage

stability

Automatic adjustment of switching

frequency

Slip compensation / Counter function

Restart after instantaneous power

-torque detection • Jump frequency

-preset speeds • S-curve acceleration &

Frequency

Setting

Signal:

Operation panel (including KP

Analogue Signal: (DC 0 ~ 10V) /

0~100%

Digital Signal: Jog speed, 8

preset speeds

Modbus (RS485) Communication

Operation panel (including KP

Digital Signal: FWD (forward) /

REV (reverse) rotation control

3 programmable input terminal: X1~X3

Response time (1~255, unit 1ms)

Refer to the F5.19~F5.21 functions setting

description.

1 set of analogue input: VI (DC 0 ~ 10V) •

Analogue filter (0~255, unit 5ms), the

dead band of analogue frequency, gain

and bias are adjustable

GENERAL SPECIFICATIONS / CONTROL CHARACTERISTICS

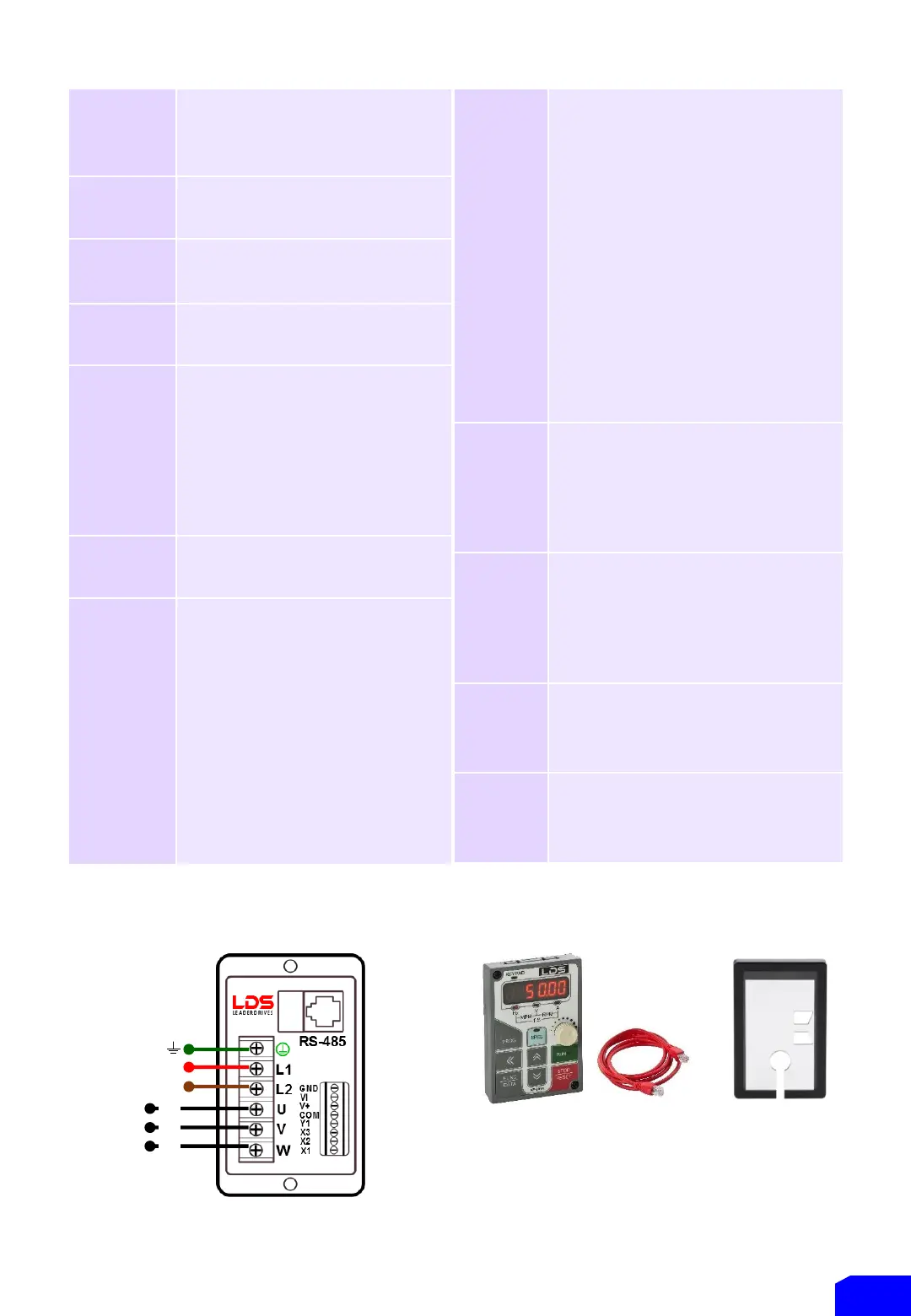

The keypad

Enable remote control of

the inverter via Modbus

(RS485) Communication.

Duplication of parameter

from Inverter to Inverter.

PORTABLE KEYPAD

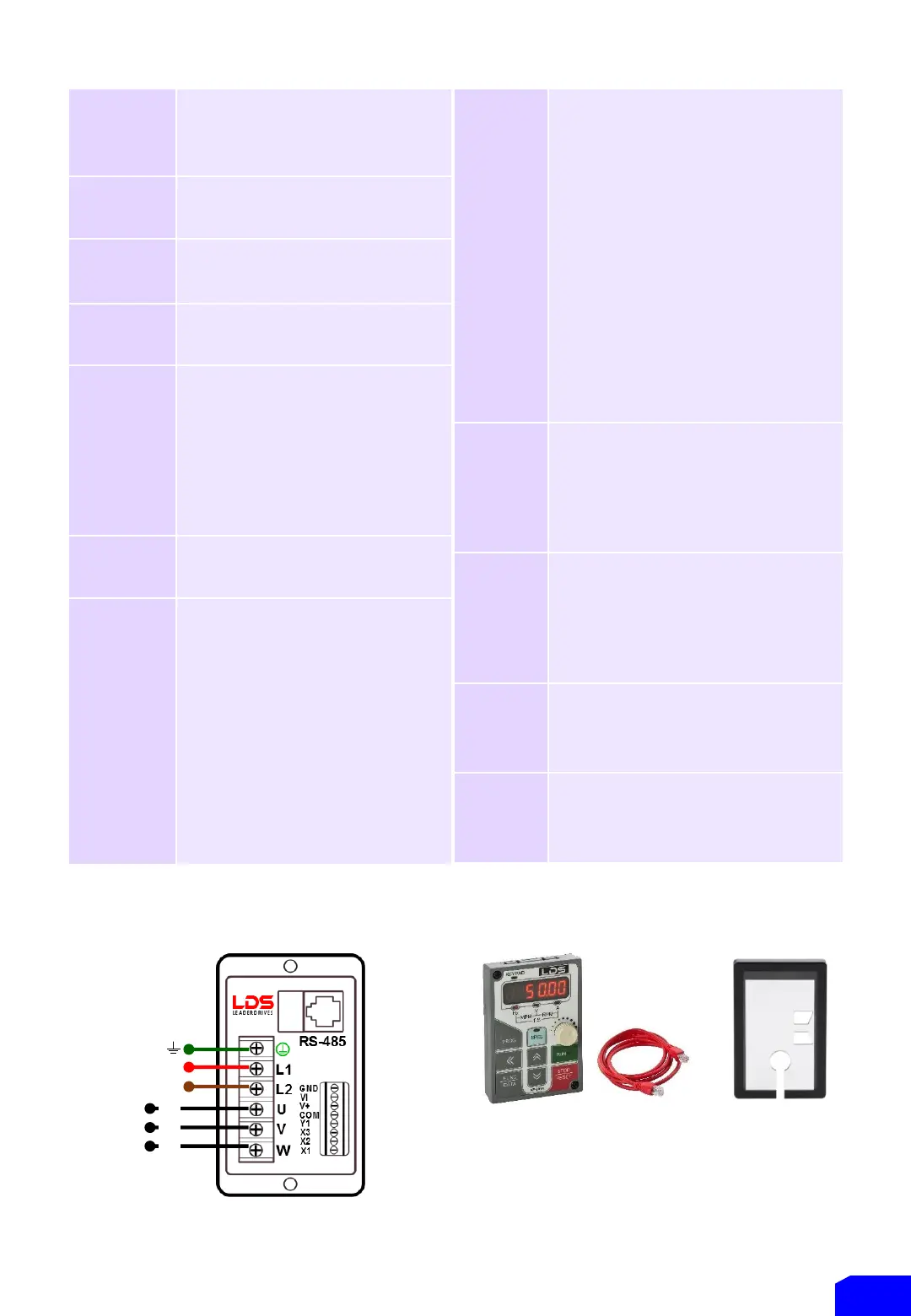

FG

AC Power Source

1Φ200V~240V

Motor

3Φ220VAC

L1

L2

U

V

W

MAIN CONTROL CIRCUIT

TERMINALS

Acrylic Protective

Cover

P 2

Loading...

Loading...