2000 Hour Intervals

Change tandem oil

Grease tandem pivots

Grease circle gearbox

Change differential oil

Change planetary hubs oil

Change hydraulic oil

SCHEDULED MAINTENANCE

PROCEDURES

AS REQUIRED MAINTENANCE PROCEDURES

Clean and Tighten Battery Terminals

WARNING: Battery gas can explode. Keep

sparks and flames away from bat-

teries. Always remove grounded (-)

battery clamp first and replace last.

The batteries are located in a compartment on the

left side of the machine.

1. Disconnect battery clamps, grounded clamp first.

2. Clean terminal and clamp with a stiff brush.

3. Install and tighten clamps, grounded clamp last.

Check Tire Pressure

WARNING: Explosive separation of a tire and

rim parts can cause serious injury

or death.

• DO NOT operate with low pressure, cuts,

bubbles, damaged rims, or missing wheel studs

and nuts.

• Always maintain correct tire pressure. DO NOT

inflate tires above the recommended level.

• When inflating tires, use a clip-on chuck and

extension hose long enough to allow you to stand

to one side and NOT in front of or over the tire

assembly.

Check tire pressure with an accurate gauge having

1 PSI (6.9 kPa) (0.07 bar) graduations.

1. Shut off air supply to hose.

2. Move gauge hand to correct pressure.

3. Lock air chuck on tire valve.

4. Turn on air supply. Stand to front or rear of

tire when air is added. Inflate tires to 35 PSI

(241 kPa) (2.41 bar).

NOTE: Tire pressure may need to be changed

for specific working conditions. Refer

to manufacturers information.

5. After tire is at correct pressure, shut off air

supply. Release chuck.

6. Inspect tire for damage.

Belt Inspection and Adjustment

1. Check belt regularly for wear. Replace if

defective.

2. Check tension of belt closest to fan midway

between pulleys. Apply a force of 20 lb. (90 N)

and check for a deflection of ¾ in. (19 mm).

3. If deflection is not within specifications, loosen

alternator mounting cap screw.

4. Tighten capscrews to 20 ft. lb. (27.12 N•m).

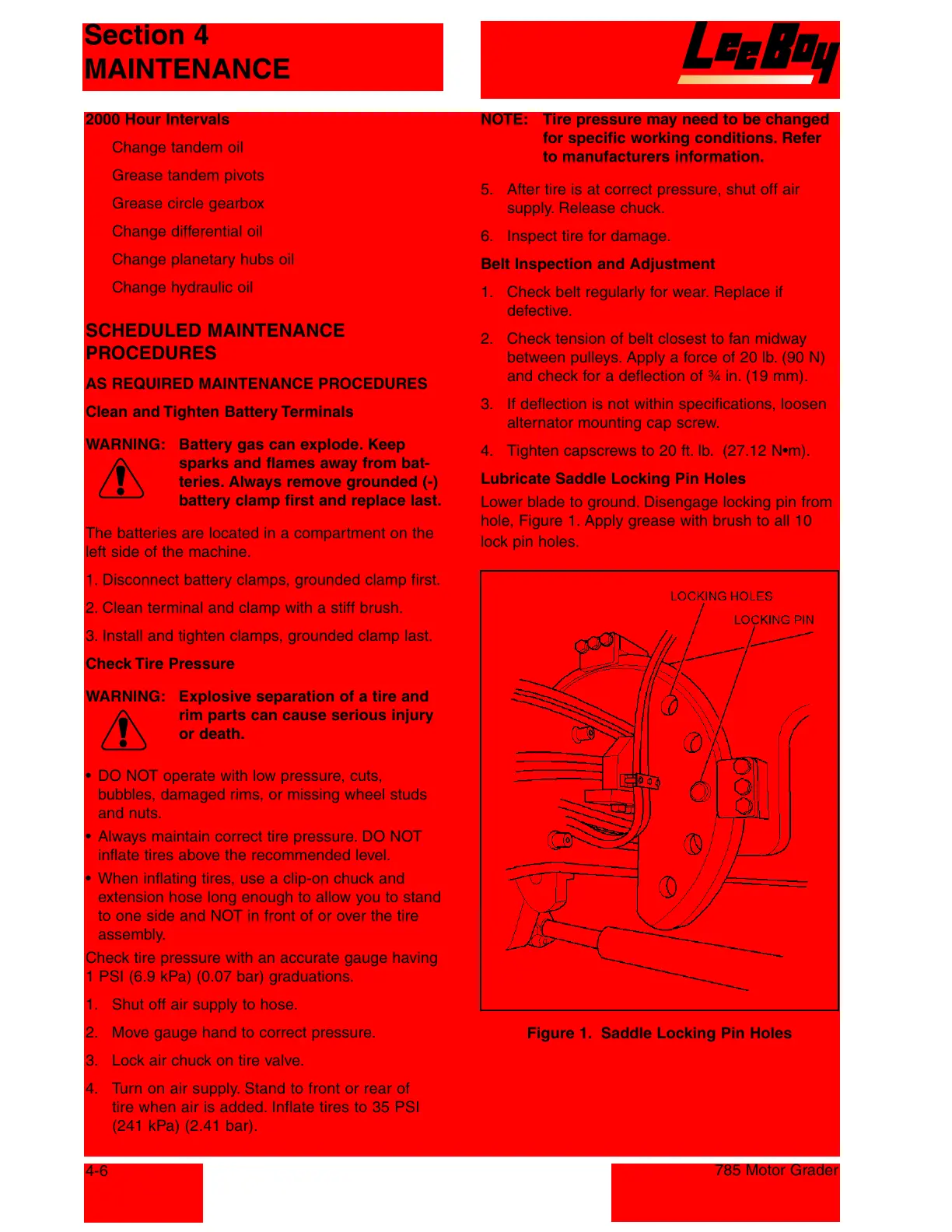

Lubricate Saddle Locking Pin Holes

Lower blade to ground. Disengage locking pin from

hole, Figure 1. Apply grease with brush to all 10

lock pin holes.

Figure 1. Saddle Locking Pin Holes

Section 4

MAINTENANCE

4-6

785 Motor Grader

Courtesy of Machine.Market

Loading...

Loading...