Lubricate Circle Gear

Clean circle, if necessary.

Lubricate all contact areas on top and bottom of

circle. Rotate circle in both directions.

Check Precleaner

Empty pre-cleaner if accumulations of dirt, dust, or

snow is up to the mark in the bowl.

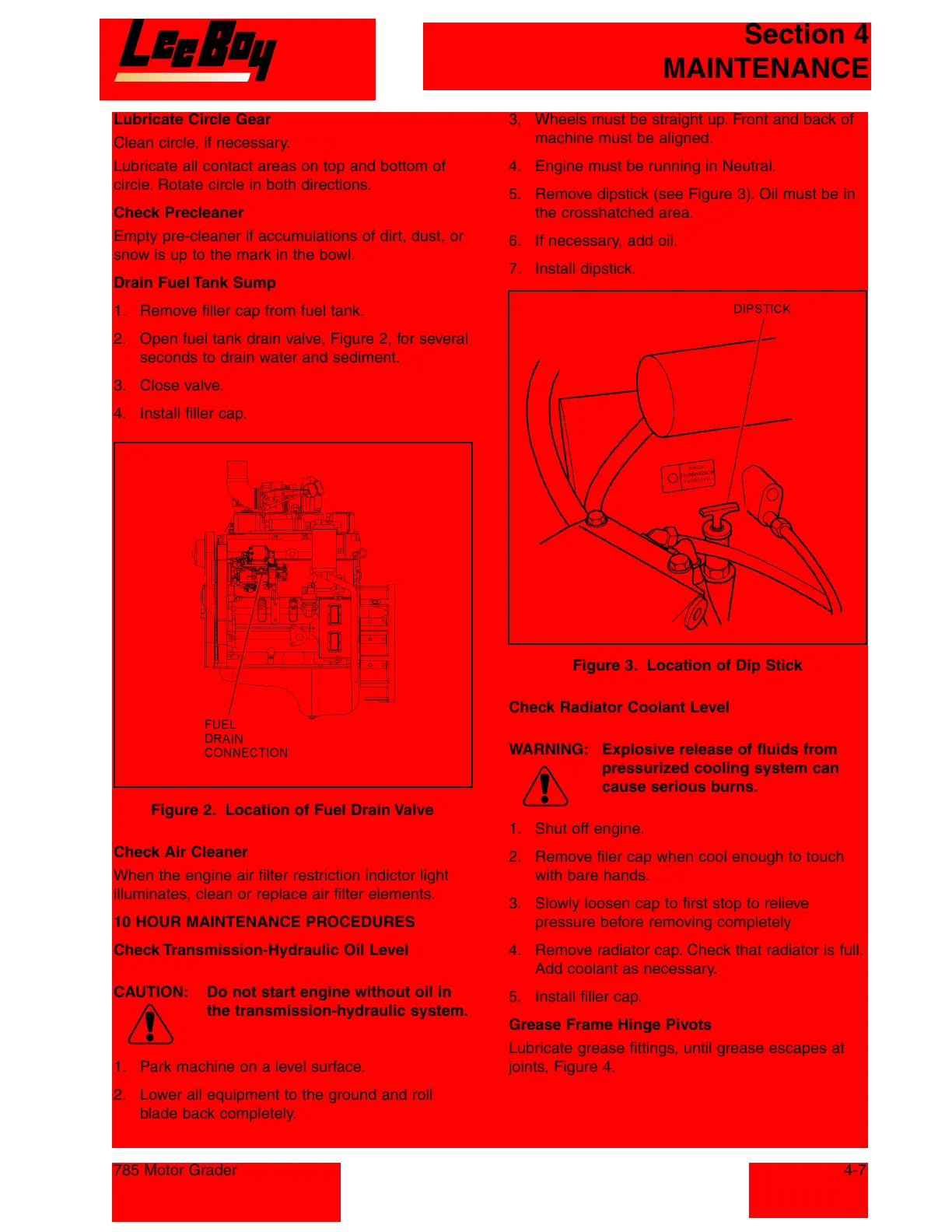

Drain Fuel Tank Sump

1. Remove filler cap from fuel tank.

2. Open fuel tank drain valve, Figure 2, for several

seconds to drain water and sediment.

3. Close valve.

4. Install filler cap.

Figure 2. Location of Fuel Drain Valve

Check Air Cleaner

When the engine air filter restriction indictor light

illuminates, clean or replace air filter elements.

10 HOUR MAINTENANCE PROCEDURES

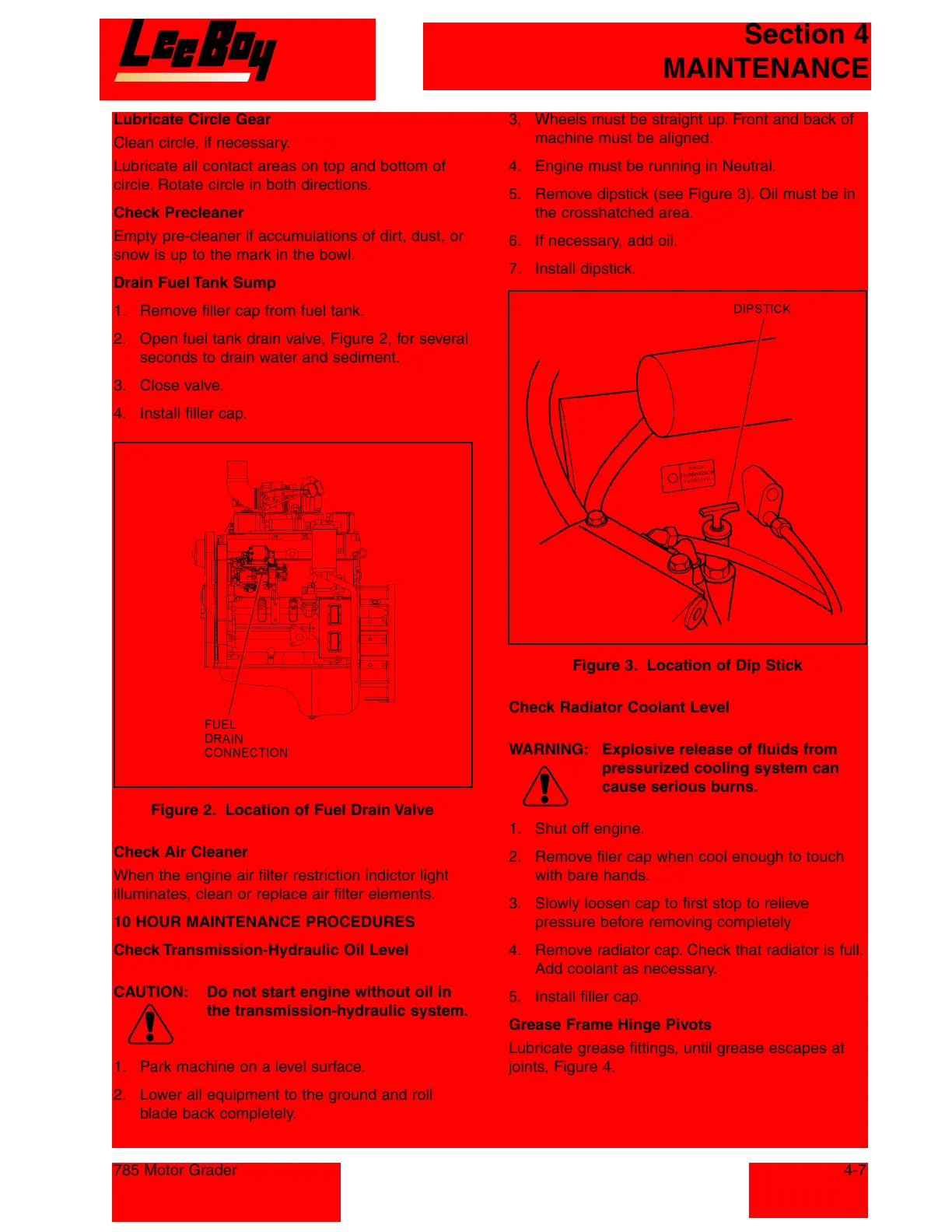

Check Transmission-Hydraulic Oil Level

CAUTION: Do not start engine without oil in

the transmission-hydraulic system.

1. Park machine on a level surface.

2. Lower all equipment to the ground and roll

blade back completely.

3, Wheels must be straight up. Front and back of

machine must be aligned.

4. Engine must be running in Neutral.

5. Remove dipstick (see Figure 3). Oil must be in

the crosshatched area.

6. If necessary, add oil.

7. Install dipstick.

Figure 3. Location of Dip Stick

Check Radiator Coolant Level

WARNING: Explosive release of fluids from

pressurized cooling system can

cause serious burns.

1. Shut off engine.

2. Remove filer cap when cool enough to touch

with bare hands.

3. Slowly loosen cap to first stop to relieve

pressure before removing completely

4. Remove radiator cap. Check that radiator is full.

Add coolant as necessary.

5. Install filler cap.

Grease Frame Hinge Pivots

Lubricate grease fittings, until grease escapes at

joints, Figure 4.

Section 4

MAINTENANCE

4-7

785 Motor Grader

Courtesy of Machine.Market

Loading...

Loading...