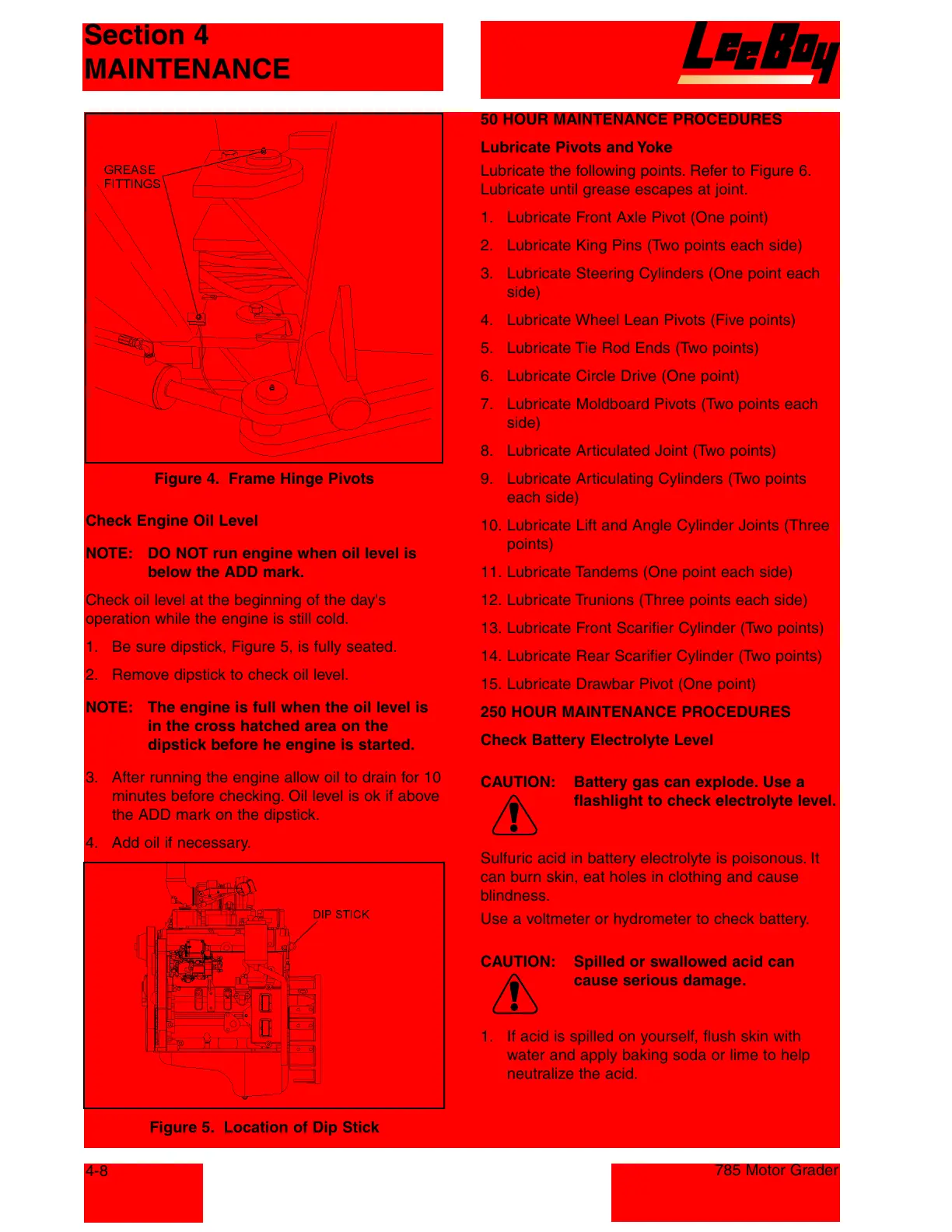

Figure 4. Frame Hinge Pivots

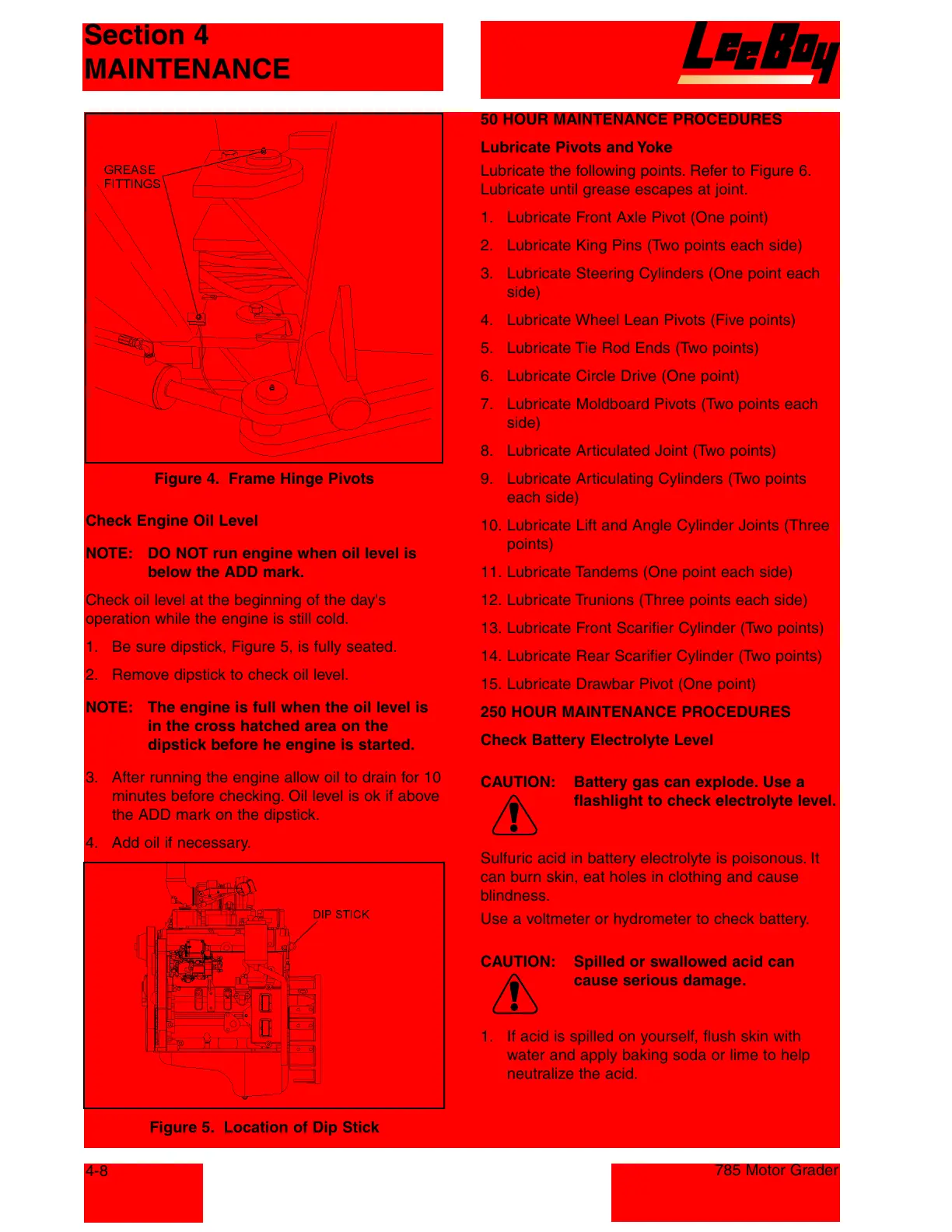

Check Engine Oil Level

NOTE: DO NOT run engine when oil level is

below the ADD mark.

Check oil level at the beginning of the day's

operation while the engine is still cold.

1. Be sure dipstick, Figure 5, is fully seated.

2. Remove dipstick to check oil level.

NOTE: The engine is full when the oil level is

in the cross hatched area on the

dipstick before he engine is started.

3. After running the engine allow oil to drain for 10

minutes before checking. Oil level is ok if above

the ADD mark on the dipstick.

4. Add oil if necessary.

Figure 5. Location of Dip Stick

50 HOUR MAINTENANCE PROCEDURES

Lubricate Pivots and Yoke

Lubricate the following points. Refer to Figure 6.

Lubricate until grease escapes at joint.

1. Lubricate Front Axle Pivot (One point)

2. Lubricate King Pins (Two points each side)

3. Lubricate Steering Cylinders (One point each

side)

4. Lubricate Wheel Lean Pivots (Five points)

5. Lubricate Tie Rod Ends (Two points)

6. Lubricate Circle Drive (One point)

7. Lubricate Moldboard Pivots (Two points each

side)

8. Lubricate Articulated Joint (Two points)

9. Lubricate Articulating Cylinders (Two points

each side)

10. Lubricate Lift and Angle Cylinder Joints (Three

points)

11. Lubricate Tandems (One point each side)

12. Lubricate Trunions (Three points each side)

13. Lubricate Front Scarifier Cylinder (Two points)

14. Lubricate Rear Scarifier Cylinder (Two points)

15. Lubricate Drawbar Pivot (One point)

250 HOUR MAINTENANCE PROCEDURES

Check Battery Electrolyte Level

CAUTION: Battery gas can explode. Use a

flashlight to check electrolyte level.

Sulfuric acid in battery electrolyte is poisonous. It

can burn skin, eat holes in clothing and cause

blindness.

Use a voltmeter or hydrometer to check battery.

CAUTION: Spilled or swallowed acid can

cause serious damage.

1. If acid is spilled on yourself, flush skin with

water and apply baking soda or lime to help

neutralize the acid.

Section 4

MAINTENANCE

4-8

785 Motor Grader

Courtesy of Machine.Market

Loading...

Loading...