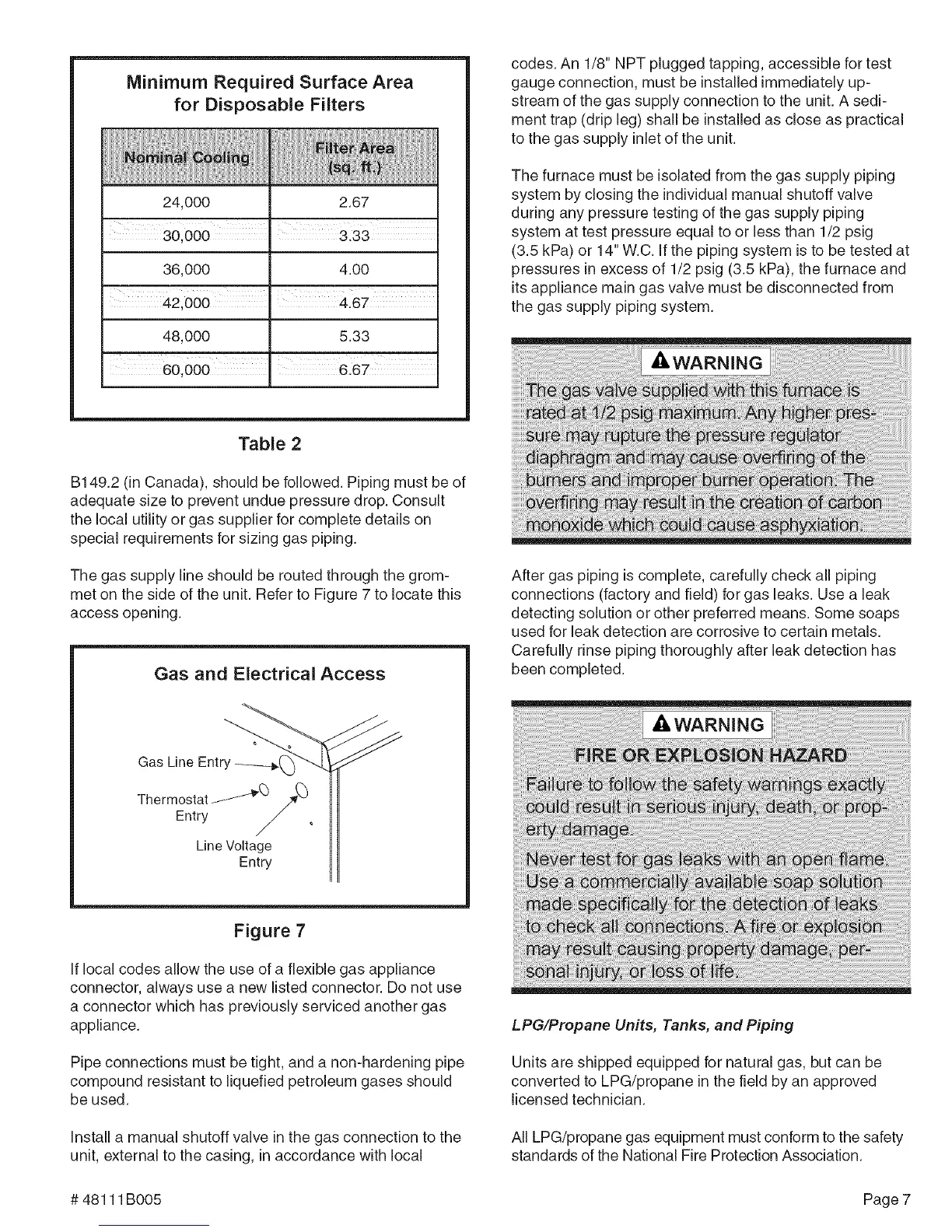

Minimum Required Surface Area

for Disposable Filters

24,000 2.67

|

30,000 I 3.33

36,000

48,000

4.00

5.33

I

60,000 _ 6.67

Table 2

B149.2 (in Canada), should be followed. Piping must be of

adequate size to prevent undue pressure drop. Consult

the local utility or gas supplier for complete details on

special requirements for sizing gas piping.

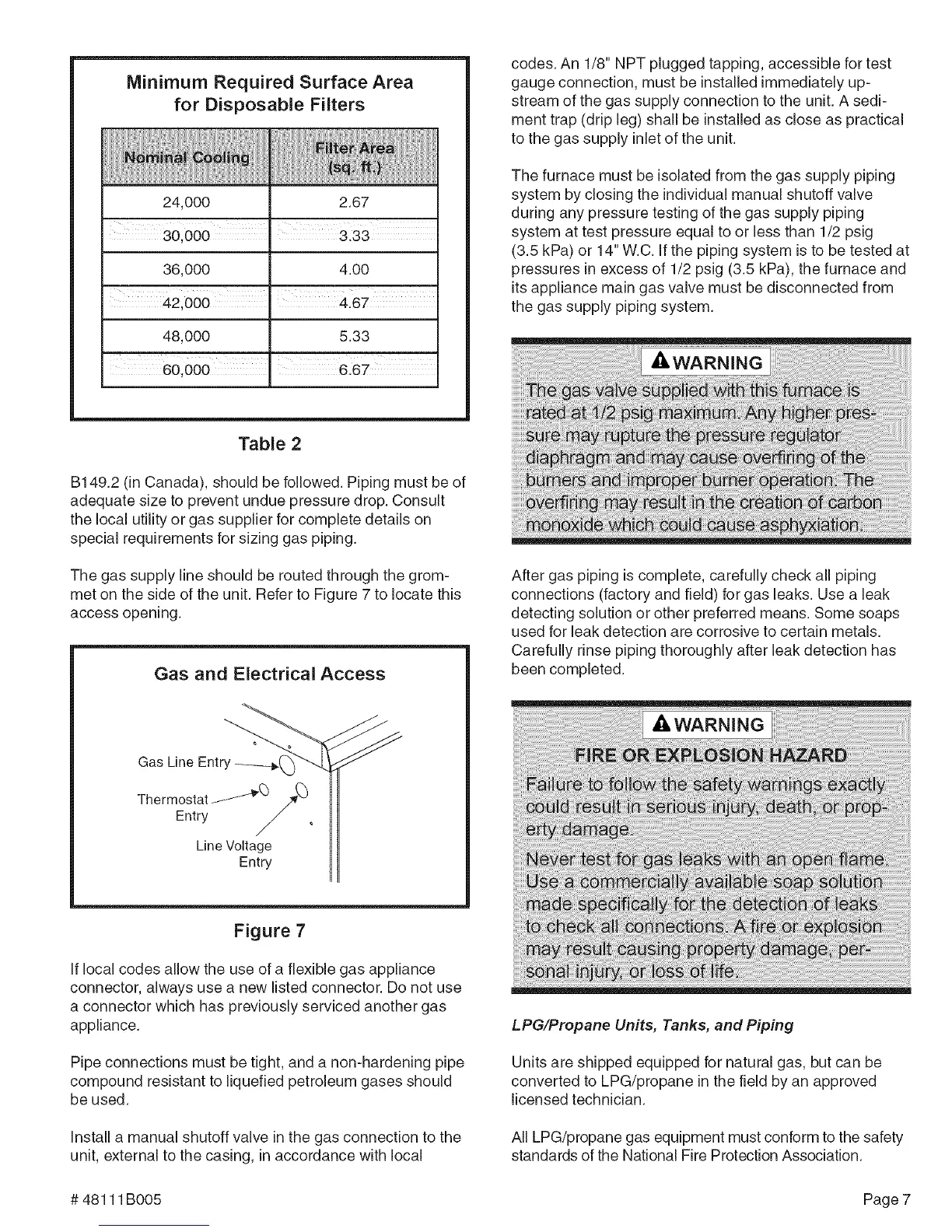

The gas supply line should be routed through the grom-

met on the side of the unit. Refer to Figure 7 to locate this

access opening.

Gas and Electrical Access

Gas Line

Thermostat _C)

Entry

Line Voltage

Entry

Figure 7

If local codes allow the use of a flexible gas appliance

connector, always use a new listed connector. Do not use

a connector which has previously serviced another gas

appliance.

Pipe connections must be tight, and a non-hardening pipe

compound resistant to liquefied petroleum gases should

be used.

Install a manual shutoff valve in the gas connection to the

unit, external to the casing, in accordance with local

codes. An 1/8" NPT plugged tapping, accessible for test

gauge connection, must be installed immediately up-

stream of the gas supply connection to the unit. A sedi-

ment trap (drip leg) shall be installed as close as practical

to the gas supply inlet of the unit.

The furnace must be isolated from the gas supply piping

system by closing the individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressure equal to or less than 1/2 psig

(3.5 kPa) or 14" W.C. If the piping system is to be tested at

pressures in excess of 1/2 psig (3.5 kPa), the furnace and

its appliance main gas valve must be disconnected from

the gas supply piping system.

After gas piping is complete, carefully check all piping

connections (factory and field) for gas leaks. Use a leak

detecting solution or other preferred means. Some soaps

used for leak detection are corrosive to certain metals.

Carefully rinse piping thoroughly after leak detection has

been completed.

LPG/Propane Units, Tanks, and Piping

Units are shipped equipped for natural gas, but can be

converted to LPG/propane in the field by an approved

licensed technician.

All LPG/propane gas equipment must conform to the safety

standards of the National Fire Protection Association.

# 48111B005 Page 7

Loading...

Loading...