conditionhasbeencorrected.Contactyourdealerifyou

desiremoreinformationaboutthisimportantsafetyfeature.

Shouldanyunusualconditionsbeobservedduringyour

inspections,callanauthorizedservicedealerimmediately.

Return Air

All return air duct connections must be tight and sealed to

unit cabinet. Supply and return air registers must be open

when the unit is in operation. Obstructions must not be

allowed to block airflow in or out of the registers.

Filters

Air filters are to be used with this heating/cooling unit.

Filters are not factory supplied in the unit. However, a filter

frame accessory is available from the manufacturer that

allows filters to be installed within the unit. [f the filter

frame accessory is not used, a filter must be installed in

the duct work by the installer. Filters must always be

installed ahead of the evaporator coil and must be kept

clean or replaced. Dirty filters will reduce the airflow of the

unit. Filters should be sized in accordance with Table 1.

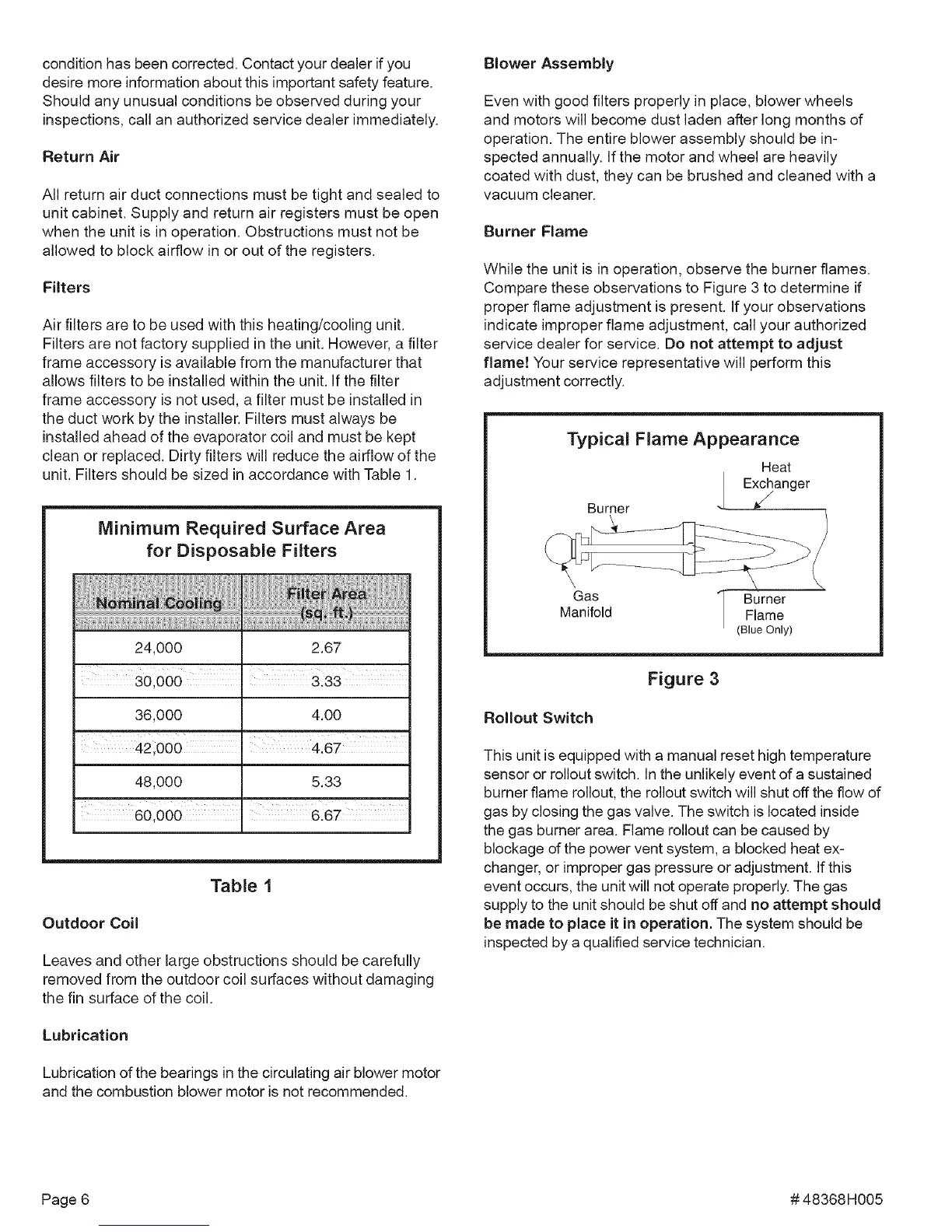

Minimum Required Surface Area

for Disposable Filters

24,000 2.67

36,000 4.00

I

421000 I 4.67

48,000 5.33

60,000 I 6.67

Table 1

Outdoor Coil

Leaves and other large obstructions should be carefully

removed from the outdoor coil surfaces without damaging

the fin surface of the coil.

Lubrication

Lubrication of the bearings in the circulating air blower motor

and the combustion blower motor is not recommended.

Blower Assembly

Even with good filters properly in place, blower wheels

and motors will become dust laden after long months of

operation. The entire blower assembly should be in-

spected annually. If the motor and wheel are heavily

coated with dust, they can be brushed and cleaned with a

vacuum cleaner.

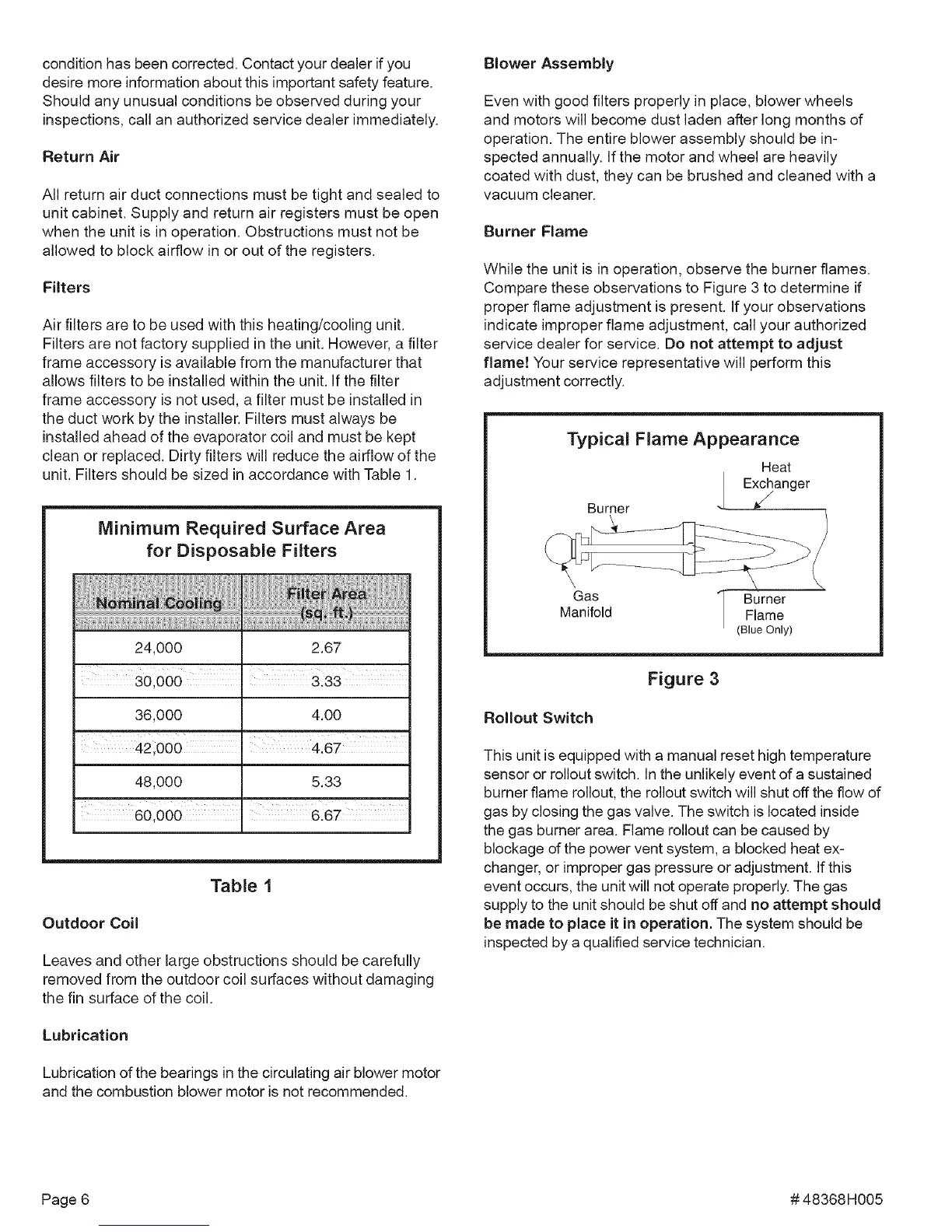

Burner Flame

While the unit is in operation, observe the burner flames.

Compare these observations to Figure 3 to determine if

proper flame adjustment is present. If your observations

indicate improper flame adjustment, call your authorized

service dealer for service. Do not attempt to adjust

flam!! Your service representative will perform this

adjustment correctly.

Typical Flame Appearance

Heat

Exchanger

Burner _¢/

Gas Burner

Manifold Flame

(Blue Only)

Figure 3

Rollout Switch

This unit is equipped with a manual reset high temperature

sensor or rollout switch. In the unlikely event of a sustained

burner flame rollout, the rollout switch will shut off the flow of

gas by closing the gas valve. The switch is located inside

the gas burner area. Flame rollout can be caused by

blockage of the power vent system, a blocked heat ex-

changer, or improper gas pressure or adjustment. If this

event occurs, the unit will not operate properly. The gas

supply to the unit should be shut off and no attempt should

be made to place it in operation. The system should be

inspected by a qualified service technician.

Page 6 #48368H005

Loading...

Loading...