506550-01Page 12 of 66 Issue 1230

Pipe and Fittings Specifications

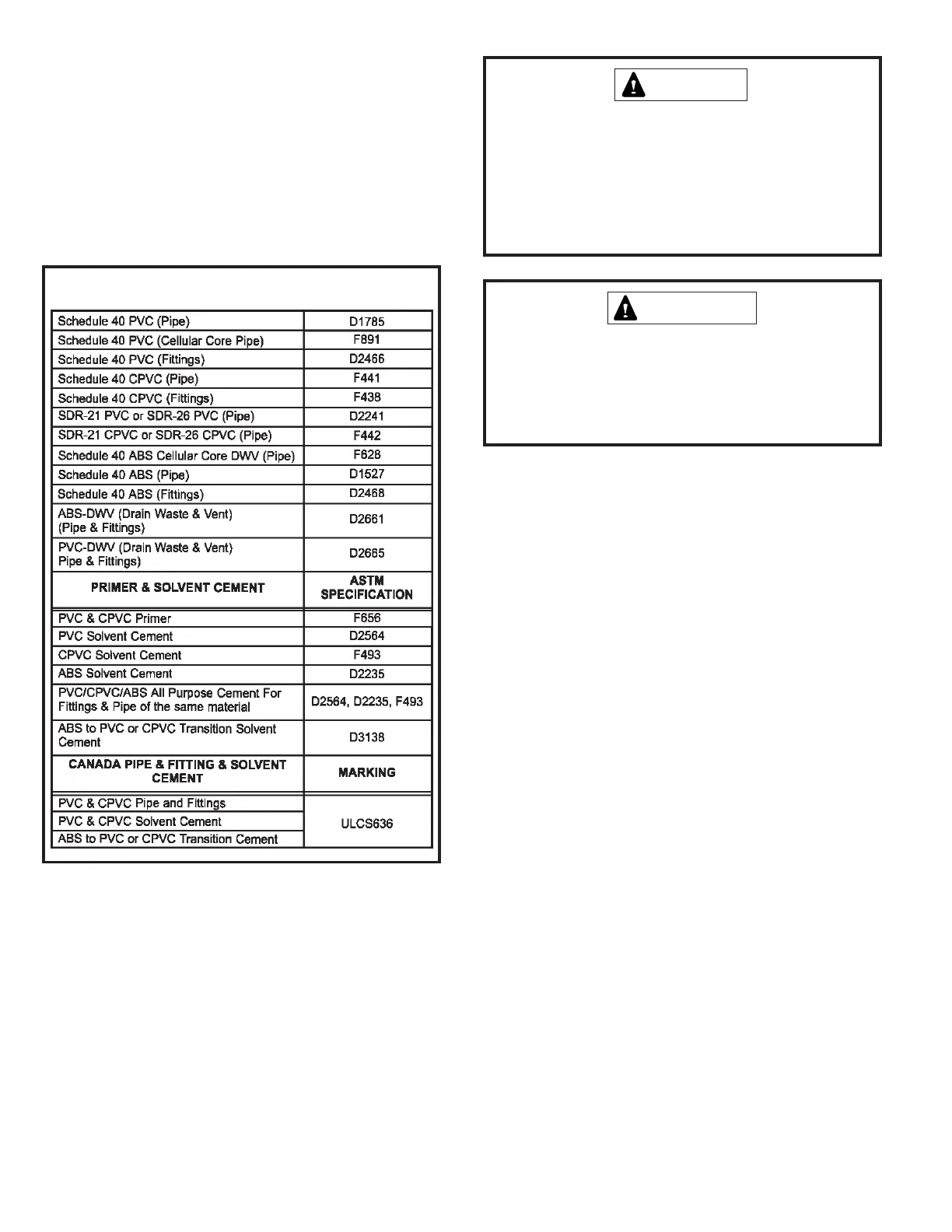

All pipe, fittings, primer and solvent cement must conform

with American National Standard Institute and the American

Society for Testing and Materials (ANSI/ASTM) standards.

The solvent shall be free flowing and contain no lumps,

undissolved particles or any foreign matter that adversely

affects the joint strength or chemical resistance of the

cement. The cement shall show no gelation, stratification,

or separation that cannot be removed by stirring. Refer to

Table 2 for approved piping and fitting materials.

PIPING AND FITTINGS SPECIFICATIONS

Table 2

IMPORTANT

The exhaust and intake connections are made of PVC.

Use PVC primer and solvent cement when using PVC

vent pipe. When using ABS vent pipe, use transitional

solvent cement to make connections to the PVC fittings

in the unit.

CAUTION

Solvent cements for plastic pipe are flammable liquids

and should be kept away from all sources of ignition.

Do not use excessive amounts of solvent cement when

makeing joints. Good ventilation should be maintained

to reduce fire hazard and to minimize breathing of

solvent vapors. Avoid contact of cement with skin and

eyes.

Use PVC primer and solvent cement or ABS solvent cement

meeting ASTM specifications, refer to Table 2. As an

alternaate, use all purpose cement, to bond ABS, PVC, or

CPVC pipe when using fittings and pipe made of the same

materials. Use transition solvent cement when bonding ABS

to either PVC or CPVC.

Low temperature solvent cement is recommended. Metal

or plastic strapping may be used for vent pipe hangers.

Uniformly apply a liberal coat of PVC primer for PVC.

Canadian Applications Only – Pipe, fittings, primer and

solvent cement used to vent (exhaust) this applicance must

be certified to ULCS636 and supplied by a single

manufacturer as part of an approved vent (exhaust) system.

In addition, the first three feet of vent pipe from the furnace

flue collar must be accessible for inspection.

Table 3 lists the available exhaust termination kits, as well

as vent pipe equivalencies which must be used when sizing

vent pipe.

Loading...

Loading...