5

REMOVE OLD FILTER AND DISCARDREMOVE OLD FILTER AND DISCARD

REMOVE OLD FILTER AND DISCARDREMOVE OLD FILTER AND DISCARD

REMOVE OLD FILTER AND DISCARD

(Figure 11)(Figure 11)

(Figure 11)(Figure 11)

(Figure 11)

NOTE: This filter may be mounted in the air handler

cabinet.

CLEAN BLOWER COMPARTMENTCLEAN BLOWER COMPARTMENT

CLEAN BLOWER COMPARTMENTCLEAN BLOWER COMPARTMENT

CLEAN BLOWER COMPARTMENT

NOTE: The air filter cannot remove dirt from blower and

ducts.

INSTALLATIONINSTALLATION

INSTALLATIONINSTALLATION

INSTALLATION

The following is a typical installation of the air cleaner on

an upflow air handler (Figure 7).

1. Place the air cleaner cabinet on the floor. Stand it

upright with the door facing you (Figure 2). If a

horizontal installation is being planned, lay the cabinet

on its side, this will help you to visualize the relative

location of all parts.

2. Unscrew the knob, remove the door (by grasping top

and pulling door away from cabinet) and set it aside.

Remove filter. Set in a safe location until the cabinet

is installed.

3. Set the cabinet next to the air handler (if possible) to

match the opening in the compartment.

If the air handler opening cannot be enlarged, a

transition fitting should be used. (Figure 3).

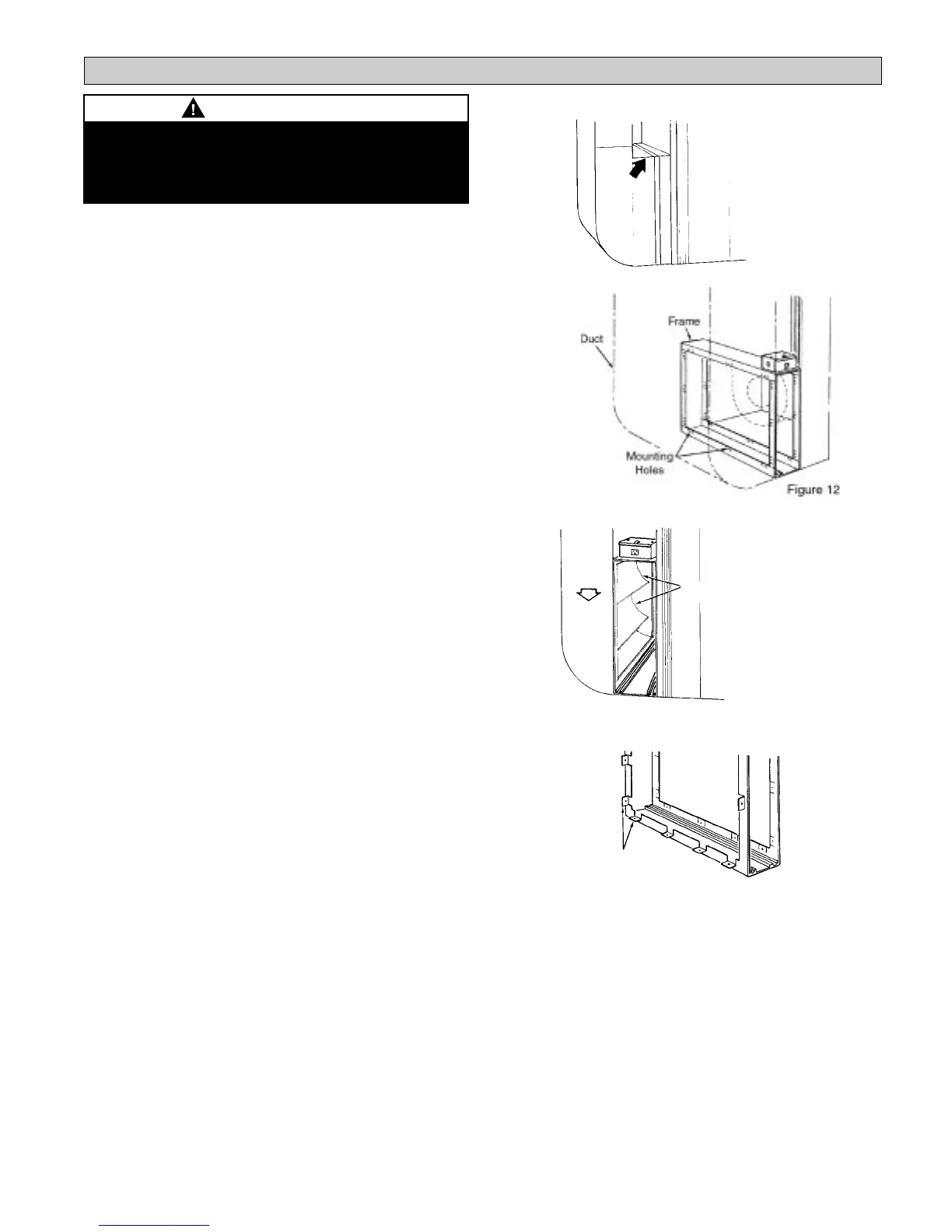

The cabinet can be attached directly (Figure 12), or a

starting collar can first be fitted to the furnace inlet. A

butt or slip joint can be used.

Securely attach the cabinet to air handler inlet, using

at least two of the mounting holes on each side of the

cabinet.

4. Using butt joint, attach duct (normally an elbow) to the

upstream side of air filter cabinet. (Note the use of the

sheet metal turning vanes inside the elbow to improve

air distribution.) (Figure 13)

NOTE: NOTE:

NOTE: NOTE:

NOTE: An optional method of attaching duct to the air

cleaner cabinet is to modify the cabinet (Figure 14) by

bending the tabs outward at a 90° angle and attaching duct

to tabs.

High Humidity EnvironmentsHigh Humidity Environments

High Humidity EnvironmentsHigh Humidity Environments

High Humidity Environments: Wrapping cabinet with 2”

foil faced insulation (foil on the outside) around the case

(excluding the insulated door) will prevent condensation

on the sides of the unit.

Transition FittingsTransition Fittings

Transition FittingsTransition Fittings

Transition Fittings

If the air duct does not fit the cabinet opening, a transition

fitting should be used. Gradual transitions are preferred

for greatest efficiency. Not more than four inches per

linear foot (approximately 20° angle) should be allowed

(Figure 3).

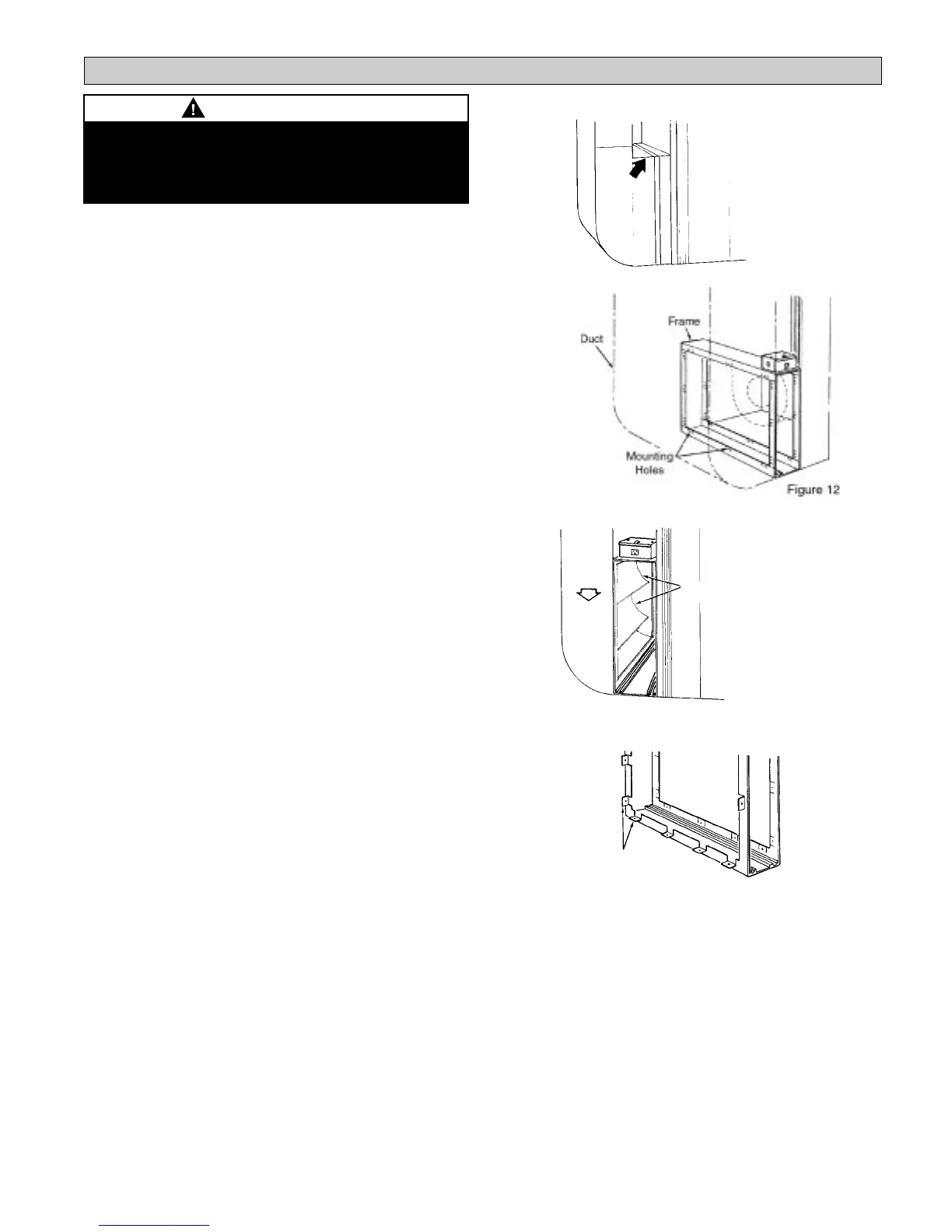

5. Connect the vertical duct section to the elbow. Wedge

a wood block between floor and elbow for support

(Figure 15).

6. Seal all joints in the return air system downstream

from the air filter with duct tape to prevent dust from

entering the air stream. Tape is usually applied on the

outside of ducts, but may also be applied on the

inside, or both.

7. With the air filter compartment installed, re-install

3” or 5” filter and door. (Figure 2)

NOTENOTE

NOTENOTE

NOTE: Please remove the plastic bag from the filter

media prior to installing the filter media into the air

cleaner cabinet. Proper disposal procedure of

plastic materials should be followed.

Figure 11

Air Flow

Turning

Vanes

Figure 13

Optional method

(Bend tabs outward at 90˚ angle)

Figure 14

InstallationInstallation

InstallationInstallation

Installation

Risk of property damage, injury or death.Risk of property damage, injury or death.

Risk of property damage, injury or death.Risk of property damage, injury or death.

Risk of property damage, injury or death.

Installation, adjustment, alteration, service and main-Installation, adjustment, alteration, service and main-

Installation, adjustment, alteration, service and main-Installation, adjustment, alteration, service and main-

Installation, adjustment, alteration, service and main-

tenance must be performed by a qualified servicetenance must be performed by a qualified service

tenance must be performed by a qualified servicetenance must be performed by a qualified service

tenance must be performed by a qualified service

technician.technician.

technician.technician.

technician.

WARNINGWARNING

WARNINGWARNING

WARNING

Loading...

Loading...