Page 21

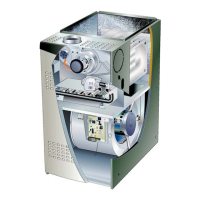

INTERIOR MAKE-UP BOX INSTALLATION

BOX

Right Side

FIGURE 21

WARNING

Fire Hazard. Use of aluminum wire with this product may

result in a re, causing property damage, severe injury

or death. Use copper wire only with this product.

Refer to FIGURE 22 for schematic wiring diagram, eld

wiring and trouble shooting.

The power supply wiring must meet Class I restrictions.

Protected by either a fuse or circuit breaker, select circuit

protection and wire size according to unit nameplate.

CAUTION

Failure to use properly sized wiring and circuit breaker

may result in property damage. Size wiring and circuit

breaker(s) per Product Specications bulletin (EHB) and

unit rating plate.

NOTE - Unit nameplate states maximum current draw.

Maximum over-current protection allowed is 15 AMP.

Holes are on both sides of the furnace cabinet to facilitate

wiring.

Install a separate (properly sized) disconnect switch near

the furnace so that power can be turned o for servicing.

Before connecting the thermostat, check to make sure

the wires will be long enough for servicing at a later date.

Make sure that thermostat wire is long enough to facilitate

future removal of blower for service.

Complete the wiring connections to the equipment. Use

the provided unit wiring and eld wiring diagram shown in

FIGURE 22. Use 18-gauge wire or larger that is suitable

for Class II rating for thermostat connections.

Electrically ground the unit according to local codes or, in

the absence of local codes, according to the current Na-

tional Electric Code (ANSI/NFPA No. 70). A green ground

wire is provided in the eld make-up box.

NOTE - The EL180UHNE furnace contains electronic

components that are polarity sensitive. Make sure that the

furnace is wired correctly and is properly grounded.

WARNING

Electric Shock Hazard. Can cause injury or death. Unit

must be properly grounded in accordance with national

and local codes.

Accessory Terminals

One line voltage “EAC” 1/4” spade terminal is provided

on the furnace integrated control. See FIGURE 24 for in-

tegrated control conguration. This terminal is energized

when the indoor blower is operating. Any accessory rated

up to one amp can be connected to this terminal with the

neutral leg of the circuit being connected to one of the pro-

vided neutral terminals. If an accessory rated at greater

than one amp is connected to this terminal, it is necessary

to use an external relay.

One line voltage “HUM” 1/4” spade terminal is provided

on the furnace integrated control. See FIGURE 24 for in-

tegrated control conguration. This terminal is energized

in the heating mode when the combustion air inducer is

operating. Any humidier rated up to one amp can be con-

nected to this terminal with the neutral leg of the circuit be-

ing connected to one of the provided neutral terminals. If

a humidier rated at greater than one amp is connected to

this terminal, it is necessary to use an external relay relay.

One 24V ”H” 1/4” spade terminal is provided on the fur-

nace integrated control. See FIGURE 24 for integrated

control conguration. The terminal is energized in the

heating mode when the combustion air inducer is operat-

ing and the pressure switch is closed. Any humidier rated

up to 0.5 amp can be connected to this terminal with the

ground leg of the circuit connected to ground or the ”C”

terminal.

Generator Use - Voltage Requirements

The following requirements must be kept in mind when

specifying a generator for use with this equipment:

• The furnace requires 120 volts + 10% (Range: 108

volts to 132 volts).

• The furnace operates at 60 Hz + 5% (Range: 57 Hz

to 63 Hz).

• The furnace integrated control requires both po-

larity and proper ground. Both polarity and proper

grounding should be checked before attempting to

operate the furnace on either permanent or tempo-

rary power.

• Generator should have a wave form distortion of

less than 5% total harmonic distortion.

Loading...

Loading...