Page 44

Gas Pressure Adjustment

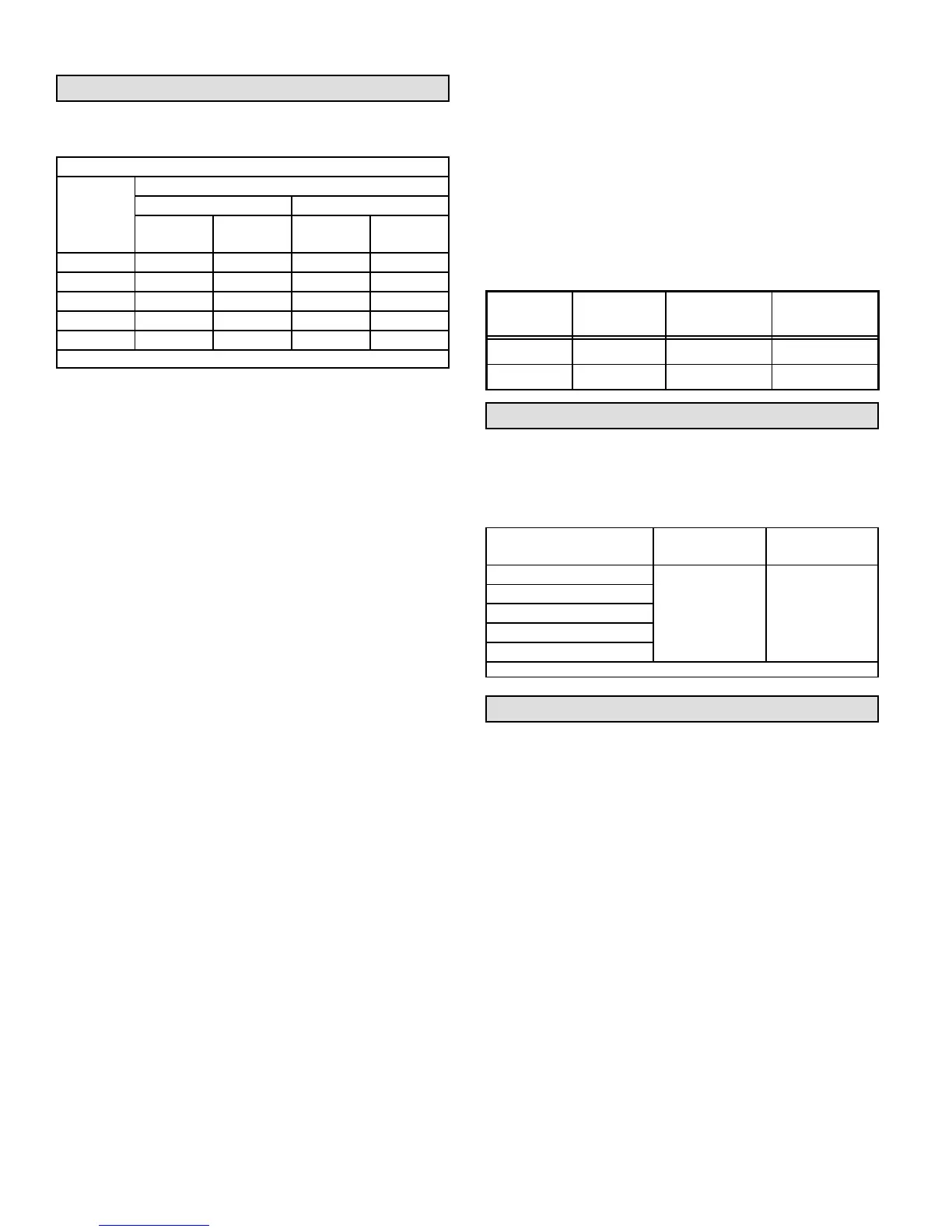

Gas Flow (Approximate)

TABLE 12

GAS METER CLOCKING CHART

EL195

Unit

Seconds for One Revolution

Natural LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

DIAL

−045 80 160 200 400

−070 55 110 136 272

−090 41 82 102 204

−110 33 66 82 164

−135 27 54 68 136

Natural−1000 btu/cu ft LP−2500 btu/cu ft

Furnace should operate at least 5 minutes before check-

ing gas flow. Determine time in seconds for two revolu-

tions of gas through the meter. (Two revolutions assures a

more accurate time.) Divide by two and compare to time

in table 12 below. If manifold pressure matches table 13

and rate is incorrect, check gas orifices for proper size and

restriction. Remove temporary gas meter if installed.

NOTE − To obtain accurate reading, shut off all other gas

appliances connected to meter.

Supply Pressure Measurement

When testing supply gas pressure, use the 1/8" N.P.T.

plugged tap or pressure post located on the gas valve to

facilitate test gauge connection. See figure 65. Check gas

line pressure with unit firing at maximum rate. Low pres-

sure may result in erratic operation or underfire. High pres-

sure can result in permanent damage to gas valve or over-

fire.

On multiple unit installations, each unit should be checked

separately, with and without units operating. Supply pres-

sure must fall within range listed in table 13.

Manifold Pressure Measurement

1 − Remove the threaded plug from the outlet side of the

gas valve and install a field−provided barbed fitting.

Connect to a manometer to measure manifold pres-

sure.

2 − Start unit and allow 5 minutes for unit to reach steady

state.

3 − While waiting for the unit to stabilize, observe the

flame. Flame should be stable and should not lift from

burner. Natural gas should burn blue.

4 − After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in table

13.

NOTE − Shut unit off and remove manometer as soon as an

accurate reading has been obtained. Take care to remove

barbed fitting and replace threaded plug.

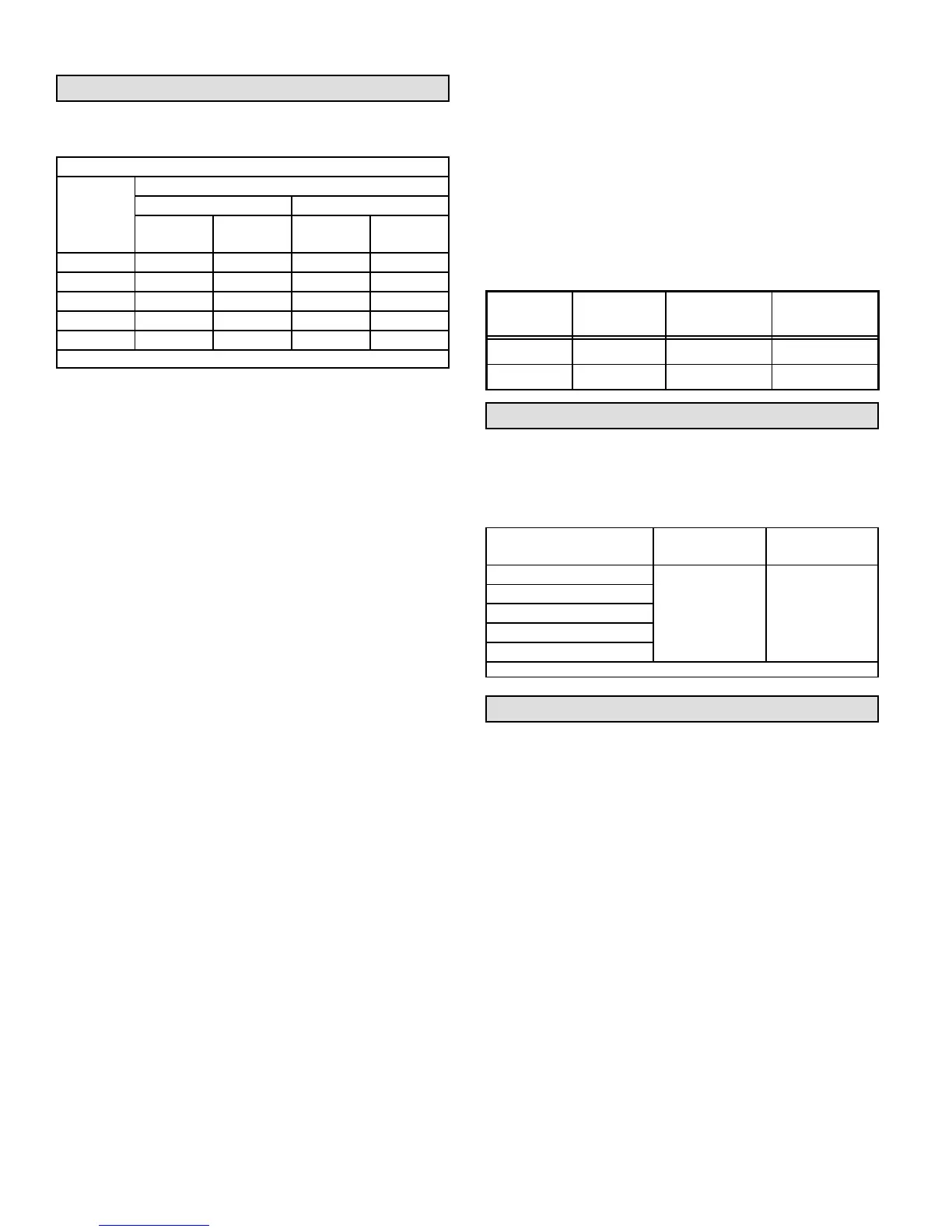

TABLE 13

Supply Line and Manifold Pressure (inches w.c.)

Unit Fuel

Manifold

Pressure

Line Pressure

All Nat 3.5 4.5 − 10.5

All LP/Propane 10.0 11.0 − 13.0

Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas flow rate before checking com-

bustion. Take combustion sample beyond the flue outlet

and compare to the tables below.

TABLE 14

EL195

Unit

CO

2

%

For

Nat

CO

2

%

For

LP

−045

7.2 − 8.2 8.6 − 9.6

−070

−090

−110

−135

The maximum carbon monoxide reading should not exceed 50 ppm.

High Altitude Information

NOTE − In Canada, certification for installations at eleva-

tions over 4500 feet (1372 m) is the jurisdiction of local au-

thorities.

EL195UHE units require no manifold pressure adjust-

ments for operation at altitudes up to 10,000 feet (3048 m).

Units installed at altitude of 4501 − 10,000 feet (1373 to

3048 m) may require a pressure switch change which can

be ordered separately. Table 15 lists conversion kit and

pressure switch requirements at varying altitudes.

The combustion air pressure switch is factory−set and re-

quires no adjustment.

Loading...

Loading...