Page 14

Refrigerant Line Limitations

You may install the unit in applications that have line set

lengths of up to 50 linear feet (15 m) with refrigerant line

sizes as outlined in table 1 (excluding equivalent length of

ttings). Size refrigerant lines greater than 50 linear feet

(15m or greater) according to the Lennox Refrigerant Pip-

ing Design and Fabrication Guidelines (Corp. 9351-L9) or

latest version.

B-Service Valves

OPERATING SERVICE VALVES

The liquid and suction line service valves are typically

used for removing refrigerant, ushing, leak testing, evac-

uating, checking charge and charging.

IMPORTANT

Only use Allen wrenches of sufcient hardness (50Rc

- Rockwell Harness Scale minimum). Fully insert the

wrench into the valve stem recess.

Service valve stems are factory-torqued (from 9 ft-lbs

for small valves, to 25 ft-lbs for large valves) to prevent

refrigerant loss during shipping and handling. Using an

Allen wrench rated at less than 50Rc risks rounding

or breaking off the wrench, or stripping the valve stem

recess.

Each valve is equipped with a service port which has a

factory-installed valve stem.

1

2

3

4

5

7

8

9

10

11

12

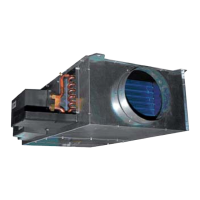

1/6 TURN

1

2

3

4

5

7

8

9

10

11

12

1/12 TURN

FIGURE 3

IMPORTANT

To prevent stripping of the various caps used, the

appropriately sized wrench should be used and tted

snugly over the cap before tightening.

TABLE 2

Torque Requirements

Part Recommended Torque

Service valve cap 8 ft.-lb. 11 NM

Sheet metal screws 16 in.-lb. 2 NM

Machine screws #10 28 in.-lb. 3 NM

Compressor bolts 90 in.-lb. 10 NM

Gauge port seal cap 8 ft.-lb. 11 NM

To Access Angle-Type Service Port:

A service port cap protects the service port core from con-

tamination and serves as the primary leak seal.

1 - Remove service port cap with an appropriately

sized wrench.

2 - Connect gauge to the service port.

3 - When testing is completed, replace service port cap

and tighten as follows:

• With Torque Wrench: Finger tighten and then tight-

en per table 2.

• Without Torque Wrench: Finger tighten and use an

appropriately sized wrench to turn an additional 1/6

turn clockwise as illustrated in gure 2.

To Open Liquid Line Service Valve:

1 - Remove stem cap with an adjustable wrench.

2 - Using service wrench and 5/16" hex head extension

if needed (part #49A71) back the stem out

counterclockwise until the valve stem just touches

the retaining ring.

3 - Replace stem cap. Tighten nger tight, then tighten

an additional 1/6 turn. Do not over torque.

To Close Liquid Line Service Valve:

1 - Remove stem cap with an adjustable wrench.

2 - Using service wrench and 5/16" hex head extension

if needed (part #49A71), turn stem clockwise to seat

the valve. Tighten rmly.

3 - Replace stem cap. Tighten nger tight, then tighten

an additional 1/6 turn. Do not over torque.

Service (Ball) Valve

Some ELS units are equipped with a full service ball valve,

as shown in gure 4. One service port that contains a

valve core is present in this valve. A cap is also provided

to seal off the service port. The valve is not rebuildable so

it must always be replaced if failure has occurred.

Opening the Suction Line Service Valve

1 - Remove the stem cap with an adjustable wrench.

2 - Using a service wrench, turn the stem

counterclockwise for 1/4 of a turn.

3 - Replace the stem cap and tighten it rmly.

Closing the Suction Line Service Valve

1 - Remove the stem cap with an adjustable wrench.

2 - Using a service wrench, turn the stem clockwise for

1/4 of a turn.

3 - Replace the stem cap and tighten rmly.

Loading...

Loading...