ii i i ii ii ; il; = iiiiiiiiiiil

The Lennox G24M multi-position gas furnace can be

installed as shipped in upflow or horizontal position with

right-hand or left-hand discharge. The furnace can easi-

ly be converted for downflow applications.

Select a location that allows for required clearances

listed on the unit rating plate. Also consider gas supply

connections, electrical supply, vent connection and

installation and service clearances [24 inches (610 mm)

at unit front].

NOTE - 1/3and 1/2hp blowermotors are equipped with ei-

ther four flexible mounting legs or three flexible legs and

one rigid leg. The dgid leg is equipped with a shipping bolt

and a flat white plastic washer (rather than the rubber

mounting grommet used witha flexible mounting leg). This

shipping bolt and flat washer must be removed before the

furnace is put into operation. Once the shippingbolt and

washer are removed, the rigid leg will not touch the fan

housing.

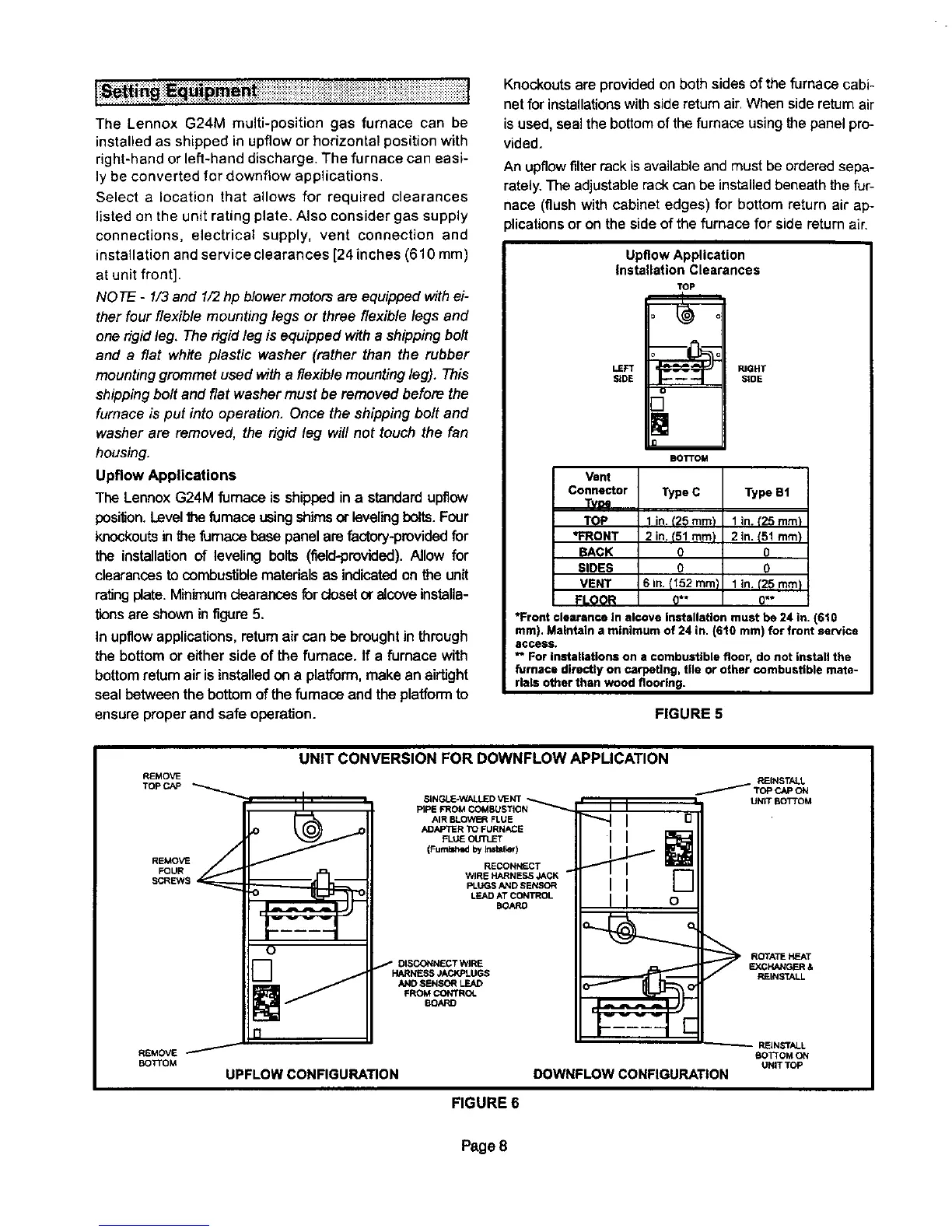

Upflow Applications

The LennoxG24M furnace is shipped in a standardupflow

position.Level_ furnaceusing shimsor levelingbolts. Four

knockoutsinthefumaca b_sepanelarefactory-providedfor

the installationof levelingbolts (field-provided).Allow for

clearancesto combustiblematerialsas indicatedon the unit

ratingplate.Minimumclearancesfor closetoralcove installa-

tionsare shownin figure5.

In upfiowapplications, returnair can be broughtin through

the bottom or either side of the furnace. If a furnace with

bottomreturnair isinstalledona platform,make an airtight

sealbetween the bottomofthe furnaceand the platformto

ensureproperand safe operation.

Knockouts areprovided on both sidesof thefurnace cabi-

net for installations with side return air.When side return air

is used, seal the bottom ofthe furnace using the panel pro-

vided.

An upflow filter rack is available and must be ordered sepa-

rately. The adjustable rack can be installed beneath the fur-

nace (flush with cabinet edges) for bottom return air ap-

)lications or on theside of the furnace for side return air.

Upflow Application

Installation Clearances

LEFT

SIDE

TOP

BOTTOM

RIGHT

S;DE

1 in. t'25 ram) 1In. (25 mm_ I

2in.(51mm) 2in.(51mm}]

0 0

0 o

6in.(152mm) 1in.(25mm}i

0" 0"

*Front clearance in alcove Installation must be 24 in. (610

ram). Maintain a minimum of 24 in. (610 rnm) for front service

eccess.

*" For installations on a combustible floor, do not install the

furnace directly on carpeting, tile or other combustible mate-

rials other than wood flooring=

Vent

Connector Type C Type BI

Twe

TOP

*FRONT

BACK

SIDES

VENT

FLOOR

FIGURE 5

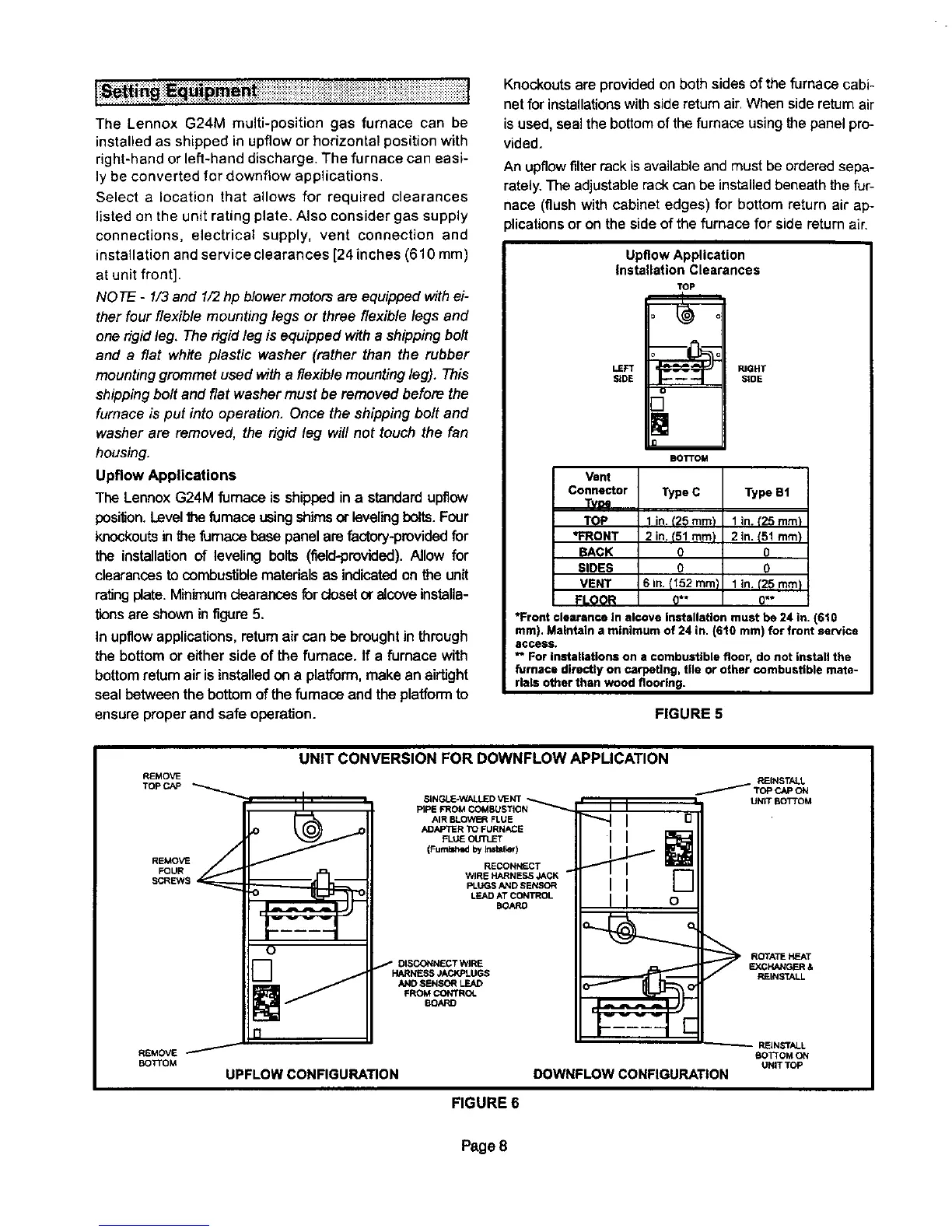

REMOVE

TOPCAP

REMOVE

FOUR

SCREWS

REMOVE

BOTTOM

UNIT CONVERSION FOR DOWNFLOW APPLICATION

SINGLE-WALLED VENT ,,.._.,..,._._

PtPE FROM COMBUSTION

AIR BLOWER FLUE

ADAPTER TO FURNACE

FLUIE OUTLET

(FumW_ed by Imta_eq

RECONNECT

WIRE HARNESS JACK

PLUGS AND SENSOR

LEAD AT CONTROL

BOARD

DISCONNECT WIRE

HARNESS JACKPLUGS

AND SENSOR LEAD

FROM CONTROL

8OARD

UPFLOW CONFIGURATION

' I I

I I o

PJEINSTALL

/ Topc,,.-oN

UNIT BOTTOM

ROrATE HEATEXCHANGER &

REINSTALL

_-- REIN_rALL

BOTTOM ON

UNIT TOP

DOWNFLOWCONFIGURATION

FIGURE 6

Page 8

Loading...

Loading...