Page 12

IV–HEATING SYSTEM SERVICE CHECKS

A–A.G.A. / C.G.A. Certification

All G27M units are A.G.A. / C.G.A. design certified with-

out modifications. Refer to the G27M Installation

Instruction for Information.

B–Gas Piping

Gas supply piping should not allow more than 0.5”W.C.

drop in pressure from unit with gas valve off and with

unit operating at second–stage heat (high fire). Supply

gas pipe must not be smaller than unit gas connection.

Refer to table 6 if pressure drop exceeds 0.5”W.C. or if

gas piping is suspect. Do not operate furnace below

nameplate minimum line pressure.

C–Testing Gas Piping

IMPORTANT

In case emergency shutdown is required, turn off

the main shut-off valve and disconnect the main

power to unit. These controls should be properly

labeled by the installer.

When pressure testing gas lines, the gas valve must be

disconnected and isolated. Gas valves can be damaged

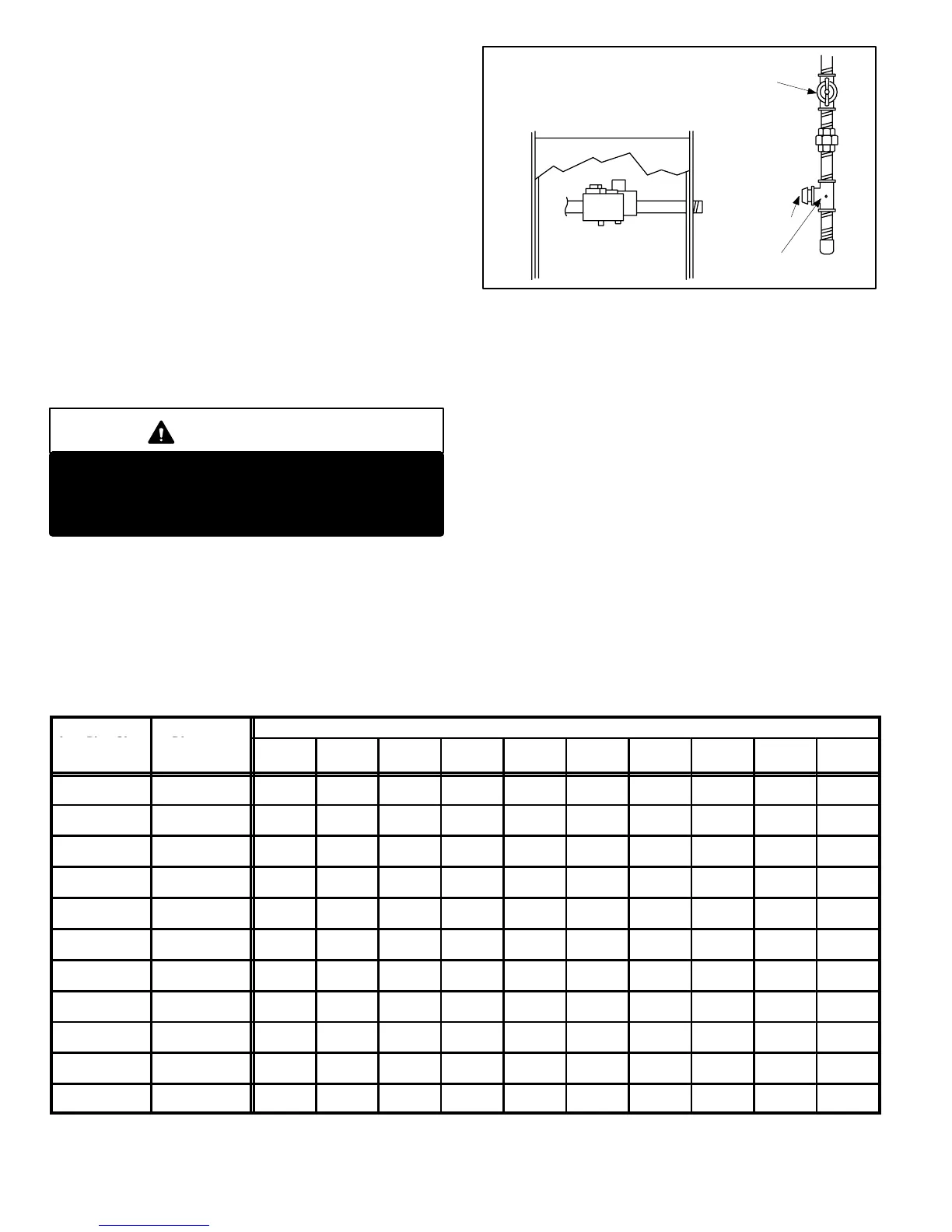

if subjected to more than 0.5psig (14” W.C.). See figure

16

.

If the pressure is equal to or less than 0.5psig

(14”W.C.), use the manual shut–off valve before

pressure testing to isolate furnace from gas supply.

FIGURE 16

MANUAL MAIN SHUT–OFF VALVE

GAS VALVE WILL NOT HOLD TEST

PRESSURE IN EXCESS OF 0.5

PSIG (14”W.C.)

GAS VALVE

CAP

GAS PIPING TEST PROCEDURE

FIELD PROVIDED

LINE PRESSURE TAP

When checking piping connections for gas leaks, use

preferred means. Kitchen detergents can cause harmful

corrosion on various metals used in gas piping. Use of a

specialty gas leak detector is strongly recommended. It

is available through Lennox under part number

31B2001. See Corp. 8411–L10, for further details.

Do not use matches, candles, flame or any other source

of ignition to check for gas leaks.

D–Testing Gas Supply Pressure

When testing supply gas pressure, connect test gauge to

inlet pressure tap (field provided). See figure 16. Check

gas line pressure with unit firing at maximum rate. Low

pressure may result in erratic operation or underfire. High

pressure can result in permanent damage to gas valve or

overfire. For natural gas units, operating pressure at unit

gas connection must be a minimum of 5.0” W.C. but no

more than 13.0”W.C. at any time.

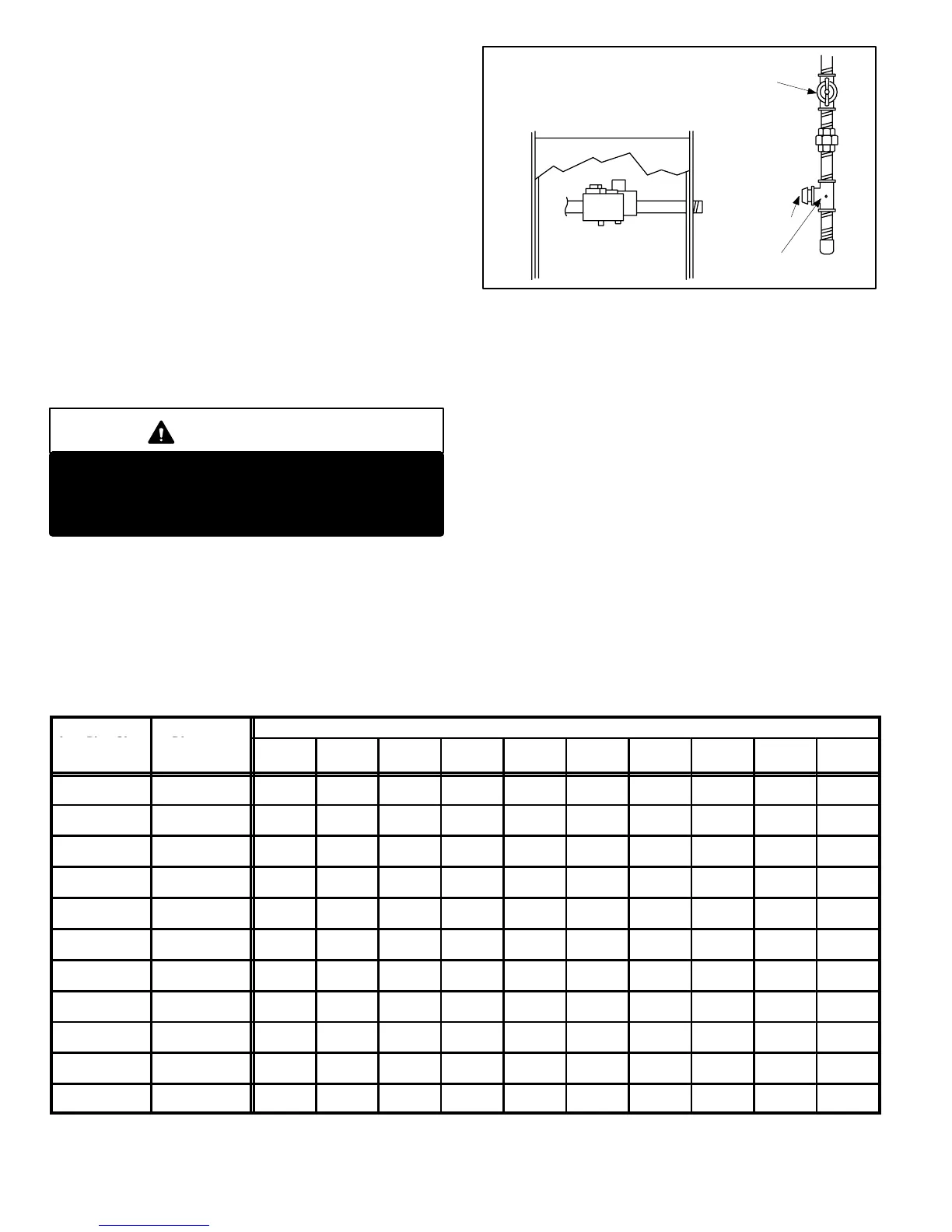

TABLE 6

GAS PIPE CAPACITY – FT

3

/HR (kL/HR)

Nominal

Internal

Length of Pipe–Feet(m)

Iron Pipe Size

–Inches(mm)

Diameter

–Inches(mm)

10

(3.048)

20

(6.096)

30

(9.144)

40

(12.192)

50

(15.240)

60

(18.288)

70

(21.336)

80

(24.384)

90

(27.432)

100

(30.480)

1/4

(6.35)

.364

(9.246)

43

(1.13)

29

(.82)

24

(.68)

20

(.57)

18

(.51)

16

(.45)

15

(.42)

14

(.40)

13

(.37)

12

(.34)

3/8

(9.53)

.493

(12.522)

95

(2.69)

65

(1.84)

52

(1.47)

45

(1.27)

40

(1.13)

36

(1.02)

33

(.73)

31

(.88)

29

(.82)

27

(.76)

1/2

(12.7)

.622

(17.799)

175

(4.96)

120

(3.40)

97

(2.75)

82

(2.32)

73

(2.07)

66

(1.87)

61

(1.73)

57

(1.61)

53

(1.50)

50

(1.42)

3/4

(19.05)

.824

(20.930)

360

(10.19)

250

(7.08)

200

(5.66)

170

(4.81)

151

(4.28)

138

(3.91)

125

(3.54)

118

(3.34)

110

(3.11)

103

(2.92)

1

(25.4)

1.049

(26.645)

680

(919.25)

465

(13.17)

375

(10.62)

320

(9.06)

285

(8.07)

260

(7.36)

240

(6.80)

220

(6.23)

205

(5.80)

195

(5.52)

1–1/4

(31.75)

1.380

(35.052)

1400

(39.64)

950

(26.90)

770

(21.80)

660

(18.69)

580

(16.42)

530

(15.01)

490

(13.87)

460

(13.03)

430

(12.18)

400

(11.33)

1–1/2

(38.1)

1.610

(40.894)

2100

(59.46)

460

(41.34)

1180

(33.41)

990

(28.03)

900

(25.48)

810

(22.94)

750

(21.24)

690

(19.54)

650

(18.41)

620

(17.56)

2

(50.8)

2.067

(52.502)

3950

(111.85)

2750

(77.87)

2200

(62.30)

1900

(53.80)

1680

(47.57)

1520

(43.04)

1400

(39.64)

1300

(36.81)

1220

(34.55)

1150

(32.56)

2–1/2

(63.5)

2.469

(67.713)

6300

(178.39)

4350

(123.17)

3520

(99.67)

3000

(84.95)

2650

(75.04)

2400

(67.96)

2250

(63.71)

2050

(58.05)

1950

(55.22)

1850

(52.38)

3

(76.2)

3.068

(77.927)

11000

(311.48)

7700

(218.03)

6250

(176.98)

5300

(150.07)

4750

(134.50)

4300

(121.76)

3900

(110.43)

3700

(104.77)

3450

(97.69)

3250

(92.03)

4

(101.6)

4.026

(102.260)

23000

(651.27)

15800

(447.39)

12800

(362.44)

10900

(308.64)

9700

(274.67)

8800

(249.18)

8100

(229.36)

7500

(212.37)

7200

(203.88)

6700

(189.72)

NOTE–Capacity given in cubic feet of gas per hour (kilo liters of gas per hour) and based on 0.60 specific gravity gas.

Loading...

Loading...