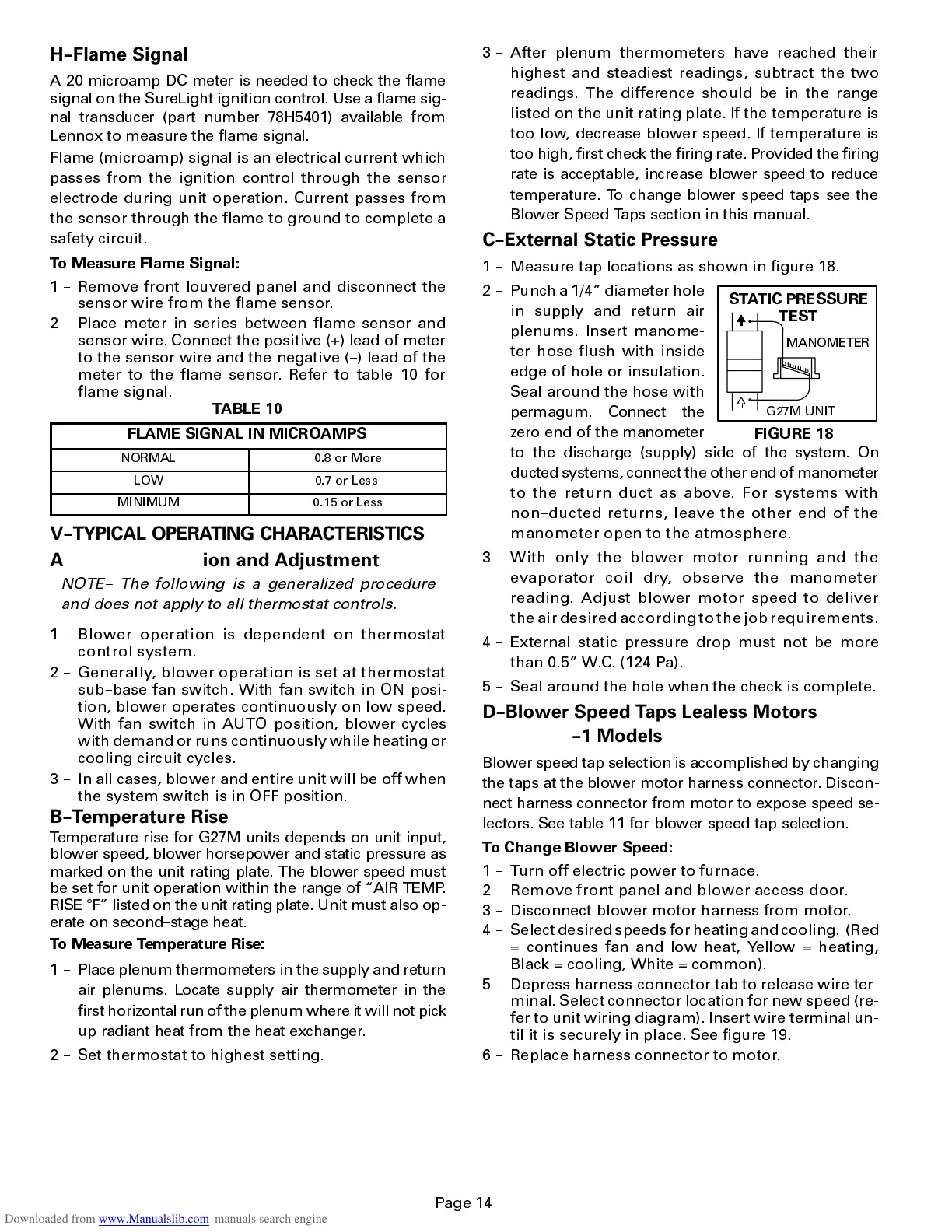

FIGURE 18

STATIC PRESSURE

TEST

MANOMETER

G27M UNIT

Page 14

H--Flame Signal

A 20 microamp DC meter is needed to check the flame

signal on the SureLight ignition control. Use a flame sig-

nal transducer (part number 78H5401) available from

Lennox to measure the flame signal.

Flame (microamp) signal is an electrical current which

passes from the ignition control through the sensor

electrode during unit operation. Current passes from

the sensor through the flame to ground to complete a

safety circuit.

To Measure Flame Signal:

1 -- Remove front louvered panel and disconnect the

sensor wire from the flame sensor.

2 -- Place meter in series between flame sensor and

sensor wire. Connect the positive (+) lead of meter

to the sensor wire and the negative (--) lead of the

meter to the flame sensor. Refer to table 10 for

flame signal.

TABLE 10

FLAME SIGNAL IN MICROAMPS

NORMAL 0.8 or More

LOW 0.7 or Less

MINIMUM 0.15 or Less

V--TYPICAL OPERATING CHARACTERISTICS

A--Blower Operation and Adjustment

NOTE-- The following is a generalized procedure

and does not apply to all thermostat controls.

1 -- Blowe r o perati on is de penden t on t hermos tat

cont rol sys tem.

2 -- Gener ally, blowe r operat ion is s et at t hermos tat

sub--base fan switch. With fan switch in ON posi-

tion, blower operates continuously on low speed.

With fan switch in AUTO position, blower cycles

with demand or runs continuously while heating or

cooling circuit cycles.

3 -- In all cases, blower and entire unit will be off when

the system switch is in OFF position.

B--Temperature Rise

Tempera ture rise for G27 M units depends on unit input,

blower speed, blower horsepo wer and stat ic pressure as

marked on the unit rating plate. The blower speed must

be set for unit operati on within the range of AIR TEMP.

RISE

q

F listed on the unit rating plate. Unit must also op-

erate on second--stage heat.

To Measure Tempera ture Rise:

1 -- Place plenum thermo mete rs in the supply and return

air plenums. Locate supply air thermom eter in the

first horizontal run of the plenum where it will not pick

up radiant heat from the heat exchanger.

2 -- Set thermostat to highest setting.

3 -- After plenum thermometers have reached their

highest and steadiest readings, subtract the two

readings. The difference should be in the range

listed on the unit rating plate. If the temperature is

too low, decrease blower speed. If temperature is

too high, first check the firing rate. Provided the firi ng

rate is acceptab le, increase blower spee d to reduce

tempera ture. To change blower speed taps see the

Blower Speed Taps section in this manual.

C--External Static Pressure

1 -- Measure tap locations as shown in figure 18.

2 -- Punch a 1/4 diameter hole

in supply and return air

plenums. Insert manome-

ter hose flush with inside

edge of hole or insulation.

Seal around the hose with

permagum . Connect the

zero end of the manometer

to the discharge (supply) side of the system. On

ducted systems, connect the other end of manometer

to t he ret urn duct as abo ve. Fo r sys tems with

non--duc ted returns , leav e the ot her end of the

manomete r op en to t he atmos phe re.

3 -- Wit h on ly t he b lower mo tor runni ng and the

evaporat or c oi l dr y, obs erve the mano meter

readin g. A djus t b lower motor sp eed to deliv er

theairdesiredaccordingtothejobrequirements.

4 -- External static pressure drop must not be more

than 0.5 W.C. (124 Pa).

5 -- Seal around the hole when the check is complete.

D--Blower Speed Taps Lealess Motors

--1 Models

Blower speed tap selection is accomplished by changing

the taps at the blower motor harness connector . Discon-

nect harness connector from motor to expose speed se-

lectors. See table 11 for blower speed tap selection.

To Change Blower Speed:

1 -- Turn off electric power to furnace.

2 -- Remove front panel and blower acc ess door.

3 -- Disconnect blower motor harness from motor.

4 -- Select desired speeds for heating and cooling. (Red

= continues fan and low heat, Yellow = heating,

Black = cooling, White = common).

5 -- Depress harness connector tab to release wire ter-

minal. Select connector location for new speed (re-

fer to unit wiring diagram). Insert wire terminal un-

til it is securely in place. See figure 19.

6 -- Replace harness connector to motor.

Loading...

Loading...