Page 5

NOTE - The G27M furnace contains electronic compo

nents that are polarity sensitive. Make sure that the fur

nace is wired correctly and is properly grounded.

CAUTION

Electrostatic discharge can affect electronic com

ponents. Take precautions during furnace instal

lation and service to protect the furnace's elec

tronic controls. Precautions will help to avoid

control exposure to electrostatic discharge by

putting the furnace, the control and the techni

cian at the same electrostatic potential. Neutral

ize electrostatic charge by touching hand and all

tools on an unpainted unit surface, such as the

gas valve or blower deck, before performing any

service procedure.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

a-Electronic Ignition

On a call for heat the SureLight control monitors the

combustion air blower pressure switch. The control

will not begin the heating cycle if the pressure switch is

closed (by-passed). Once the pressure switch is deter

mined to be open, the combustion air blower is ener

gized. When the differential in the pressure switch is

great enough, the pressure switch closes and a 15-se

cond pre-purge begins. If the pressure switch is not

proven within 2-1/2 minutes, the control goes into

Watchguard-Pressure Switch mode for a 5-minute re-

set period.

After the 15-second pre-purge period, the SureLight

ignitor warms up for 20 seconds after which the gas

valve opens for a 4-second trial for ignition. The ignitor

stays energized for the first second of the 4-second

trial. If ignition is not proved during the 4-second peri

od, the control will try four more times. After a total of

five trials for ignition (including the initial trial), the con

trol goes into Watchguard-Flame Failure mode. After a

60-minute reset period, the control will begin the igni

tion sequence again.

The SureLight control board has an added feature that

prolongs the life of the ignitor. After a successful igni

tion, the SureLight control utilizes less power to ener

gize the ignitor on successive calls for heat. The control

continues to ramp down the voltage to the ignitor until

it finds the lowest amount of power that will provide a

successful ignition. This amount of power is used for

255 cycles. On the 256th call for heat, the control will

again ramp down until the lowest power is determined

and the cycle begins again.

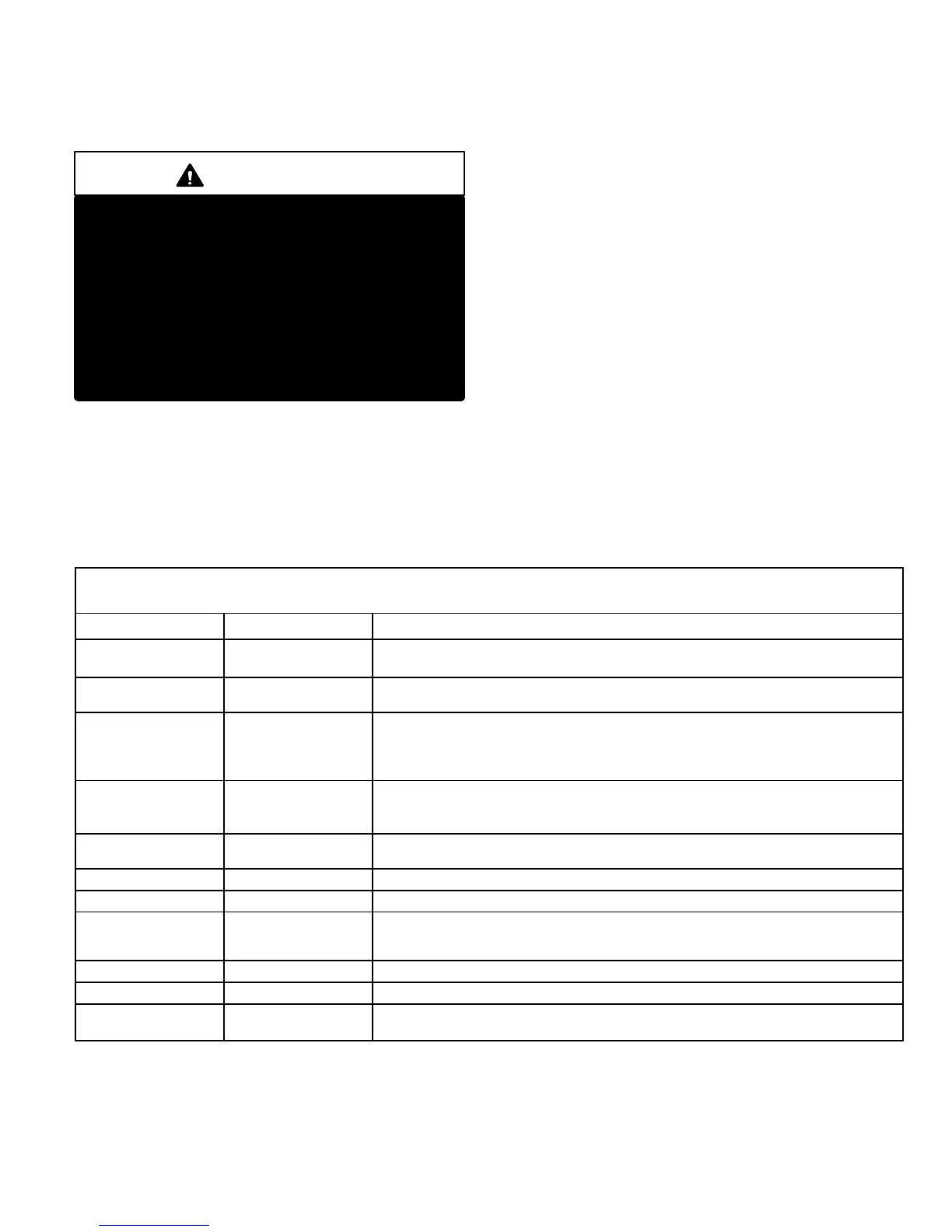

TABLE 1

DIAGNOSTIC CODES

MAKE SURE TO ID LED'S CORRECTLY: REFER TO INSTALLATION INSTRUCTIONS FOR CONTROL BOARD LAYOUT.

LED #1 LED #2 DESCRIPTION

SIMULTANEOUS

SLOW FLASH

SIMULTANEOUS

SLOW FLASH

Power - Normal operation

Also signaled during cooling and continues fan.

SIMULTANEOUS FAST

FLASH

SIMULTANEOUS FAST

FLASH

Normal operation - signaled when heating demand initiated at thermostat.

SLOW FLASH ON

Primary or Secondary limit open. Units with board 63K8901 or 24L85: Limit must

close within 5 trials for ignition or board goes into one hour limit Watchguard. Units

with board 56L83: Limit must close within 3 minutes or board goes into one hour

limit Watchguard.

OFF SLOW FLASH

Pressure switch open or has opened 5 times during a single call for heat; OR:

Blocked inlet/exhaust vent; OR: Condensate line blocked; OR: Pressure switch

closed prior to activation of combustion air blower.

ALTERNATING SLOW

FLASH

ALTERNATING SLOW

FLASH

Watchguard - burners fail to ignite.

SLOW FLASH OFF

Flame sensed without gas valve energized.

ON SLOW FLASH

Rollout switch open. OR: 9 pin connector improperly attached.

ON

ON

OFF

ON

OFF

ON

Circuit board failure or control wired incorrectly.

FAST FLASH SLOW FLASH

Main power polarity reversed. Switch line and neutral.

SLOW FLASH FAST FLASH

Low flame signal. Measures below .7 microAmps. Replace flame sense rod.

ALTERNATING FAST

FLASH

ALTERNATING FAST

FLASH

Improper main ground or line voltage below 75 volts; OR: Broken ignitor; OR: Open

ignitor circuit.

NOTE - Slow flash equals 1 Hz (one flash per second). Fast flash equals 3 Hz (three flashes per second). Drop out flame sense current < 0.15 microAmps

Loading...

Loading...