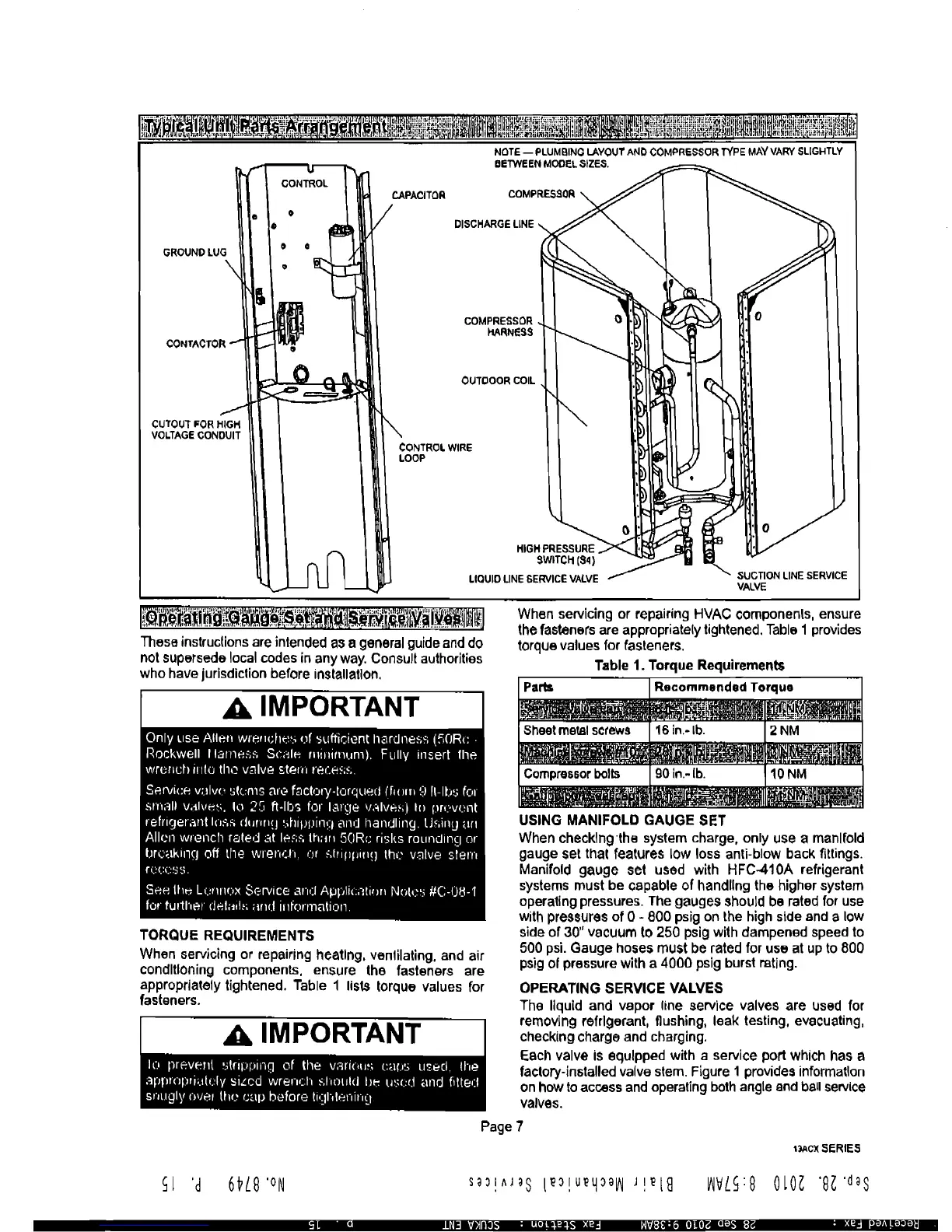

DISCi"IARGE

LINE

CONTROL

WIRE

LOOP

NOTE

-

PLUMBING

LAYO\JT

AND

COMPRESSOR

TYPE

MAY

VAFN

SLIGHTLY

COMPRESSOR

HARNESS

OUTDOOR

COIL

SUCTION

LINE

SERVICE

HIGH

PRESSURE

$WITCI1

(S~l

L10UIO

LINE

6ERVICE

VALVE

COMPRESSOR

IlETWI:I:N

MODEL

SIZES.

VALVE

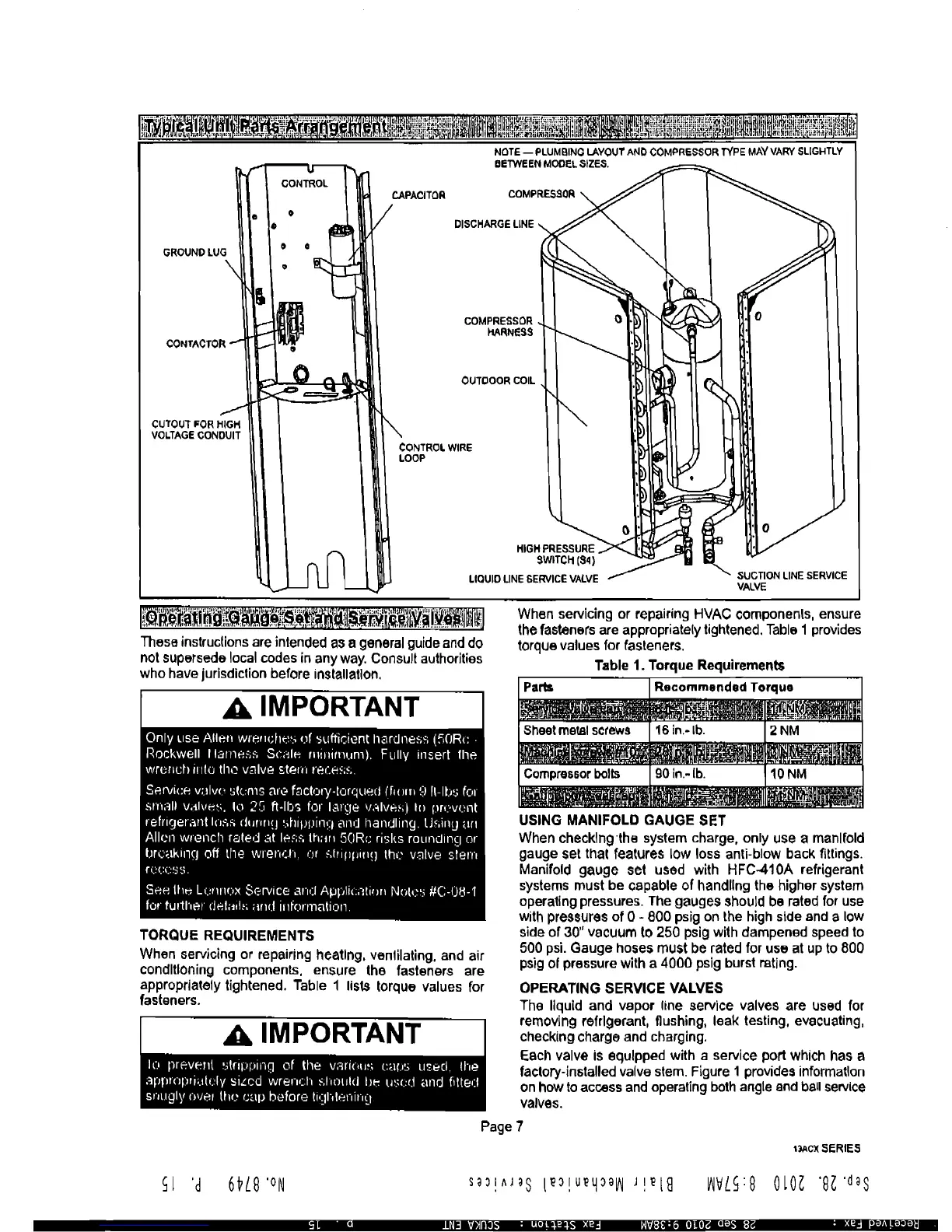

When servicing or repairing HVAC components, ensure

the fasteners are appropriately tightened.

Table

1 provides

torque values for fasteners.

Table

1. Torque Requirements

Recommended Torque

TORQUE REQUIREMENTS

When servicing or repairing heating, ventilating, and air

conditioning components, ensure the fasteners are

appropriately tightened, Table

1 lists torque values for

fasteners,

USING MANIFOLD GAUGE SET

When checking

"the

system charge, only use a manifold

gauge set that features low loss anti-blow back fillings.

Manifold gauge set used with

HFC-410A

refrigerant

systems must

be

capable

of

handling the higher system

operating pressures. The gauges should be rated for use

With

pressures

of

0 - 800 psig on the high side and a

loW

side

of

3D"

vacuum

to

250

psig with dampened speed to

500

psi. Gauge hoses

must

be rated for use at up to

800

psig of pressure with a

4000

psig burst rating.

OPERATING

SERVICE

VALVES

The liquid and vapor line service valves are

lJsed

for

removing refrigerant, flushing, leak testing, evacuating,

checking charge and charging,

Each valve is equipped with a service port which has

a

factory-installed valve stem. Figure 1 provides informatIon

on how

to

access and operating both angle and

ball

service

valves.

Page 7

IJACl<

SERIES

Sl

'd

6VL8

'oN

1

tl·"W!It'a,

Loading...

Loading...