Page 16

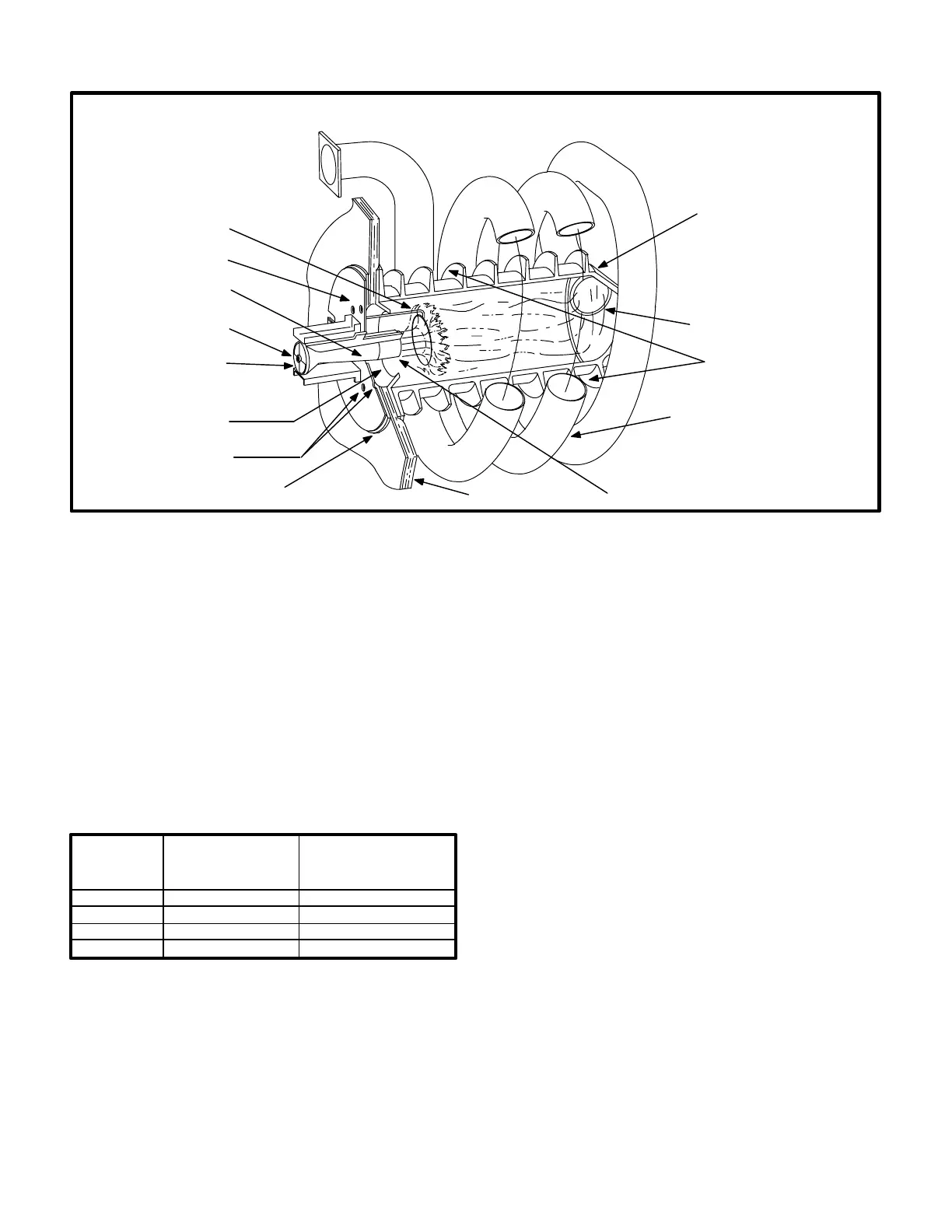

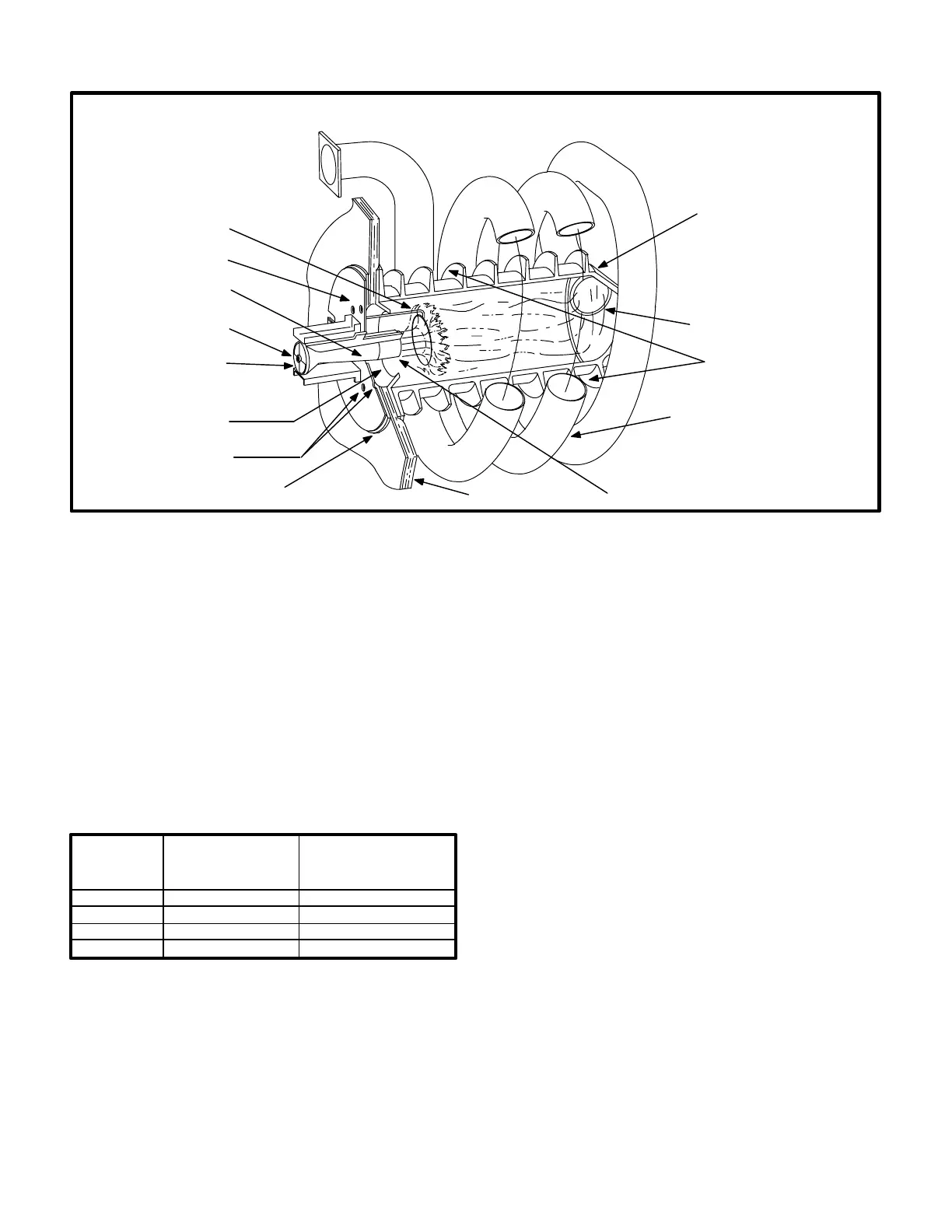

FIGURE 9

GCS16 HEAT EXCHANGE ASSEMBLY

ORIFICE

BURNER PLATE

HELICAL ALUMINIZED

STEEL TUBE

EXHAUST

(SECONDARY)

CAST IRON

CYLINDRICAL

HEAT EXCHANGER

(PRIMARY)

BURNER CONE

GASKET

BURNER

HEAT FINS

EXHAUST PORT

NON-ADJUSTABLE

ENDCAP

AIR OPENINGS

INSULATION

FLAME SPREADER

-50, -75, ONLY

RETENTION RING

1-Heat Exchanger (Figure 9)

All units use a cast iron cylindrical heat exchanger (prima

ry) encircled by helical aluminized steel tube exhaust (sec

ondary). Heat is transferred to the airstream from all sur

faces of the primary and secondary. A single inshot burner

is directed at a spreader in the heat exchanger and a com

bustion air blower is used to pull combustion air through

the heat exchanger. Heat exchangers are configured as

shown in Table 1.

TABLE 1

Btuh

Heat Exchanger

(Primary)

Size

Heat Exchanger

(Secondary)

No. of Wraps Around

Primary

50,000

75,000

100,000

125,000

Small

Large

2

3

4

5

Small

Large

2-Burner Assembly (Figures 10 and 11)

The burner is controlled by the spark electrode, flame

sensing electrode, gas valve GV1 and combustion air

blower B6. The spark electrode, flame sensing electrode

and gas valve GV1 are directly controlled by ignition con

trol A3. Ignition control A3 is controlled by combustion air

blower B6. Combustion air blower B6 is controlled by heat

ing demand from the thermostat or control system.

The burner is factory set and does not require adjustment.

Burner end caps (if used - see figure 9 ) are non-adjust

able. Flame can be viewed through air holes in the burner

plate. A peep hole is provided in the burner access panel

on units without a burner enclosure. If a burner enclosure

is used, a flame viewing glass is provided in the enclosure.

Combustion takes place at the heat exchanger entrance.

Combustion air is pulled through the burner by the com

bustion air blower (B6). Air is mixed with fuel in the burner.

The mixture is then ignited by the spark electrode and the

resultant flame is directed against a flame spreader. The

spreader disrupts and spreads the flame. The burner cone

surrounding the entrance to the heat exchanger directs

additional combustion air into the flame. A flame retention

ring located in the burner end is used to keep flame from

lifting off the burner head. As hot exhaust gases are drawn

through the heat exchanger by the combustion air blower,

exhaust gases are expelled from the heat exchanger sec

ondary and fresh air/gas mixture is drawn in through the

burner and supply air holes. Supply air blower B3, con

trolled by blower relay K25 forces air across all surfaces of

the heat exchanger primary and secondary to extract the

heat of combustion.

Loading...

Loading...