Page 17

a-Burners

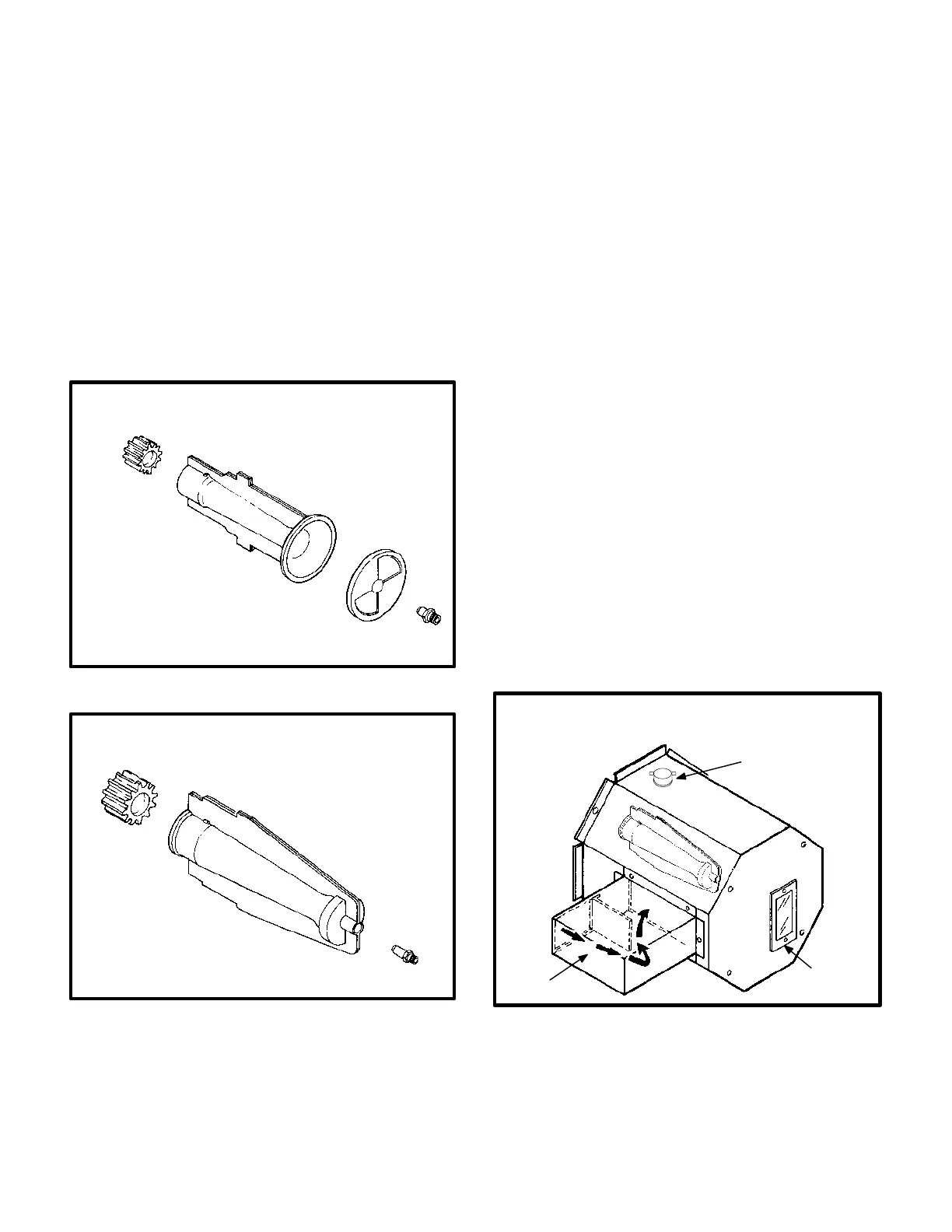

All units use an inshot burner (see figures 10 and 11). A

flame retention ring located in the burner end is used to

keep flame from lifting off the burner. The flame is aimed at

a round flame spreader located in the combustion cham

ber. The spreader distributes the flame evenly around the

circumference of the heat exchanger. Burners in 50,000

and 75,000 Btuh heat exchangers use a separate nonad

justable endcap (see figure 10). Burners in 100,000 and

125,00 Btuh heat exchangers do not use an endcap (see

figure 11).

INSHOT BURNER

50,000 and 75,000 Btuh HEAT EXCHANG

ERS

FIGURE 10

FLAME

RETENTION

RING

BURNER

SEPARATE

NON-ADJUSTABLE

ENDCAP

ORIFICE

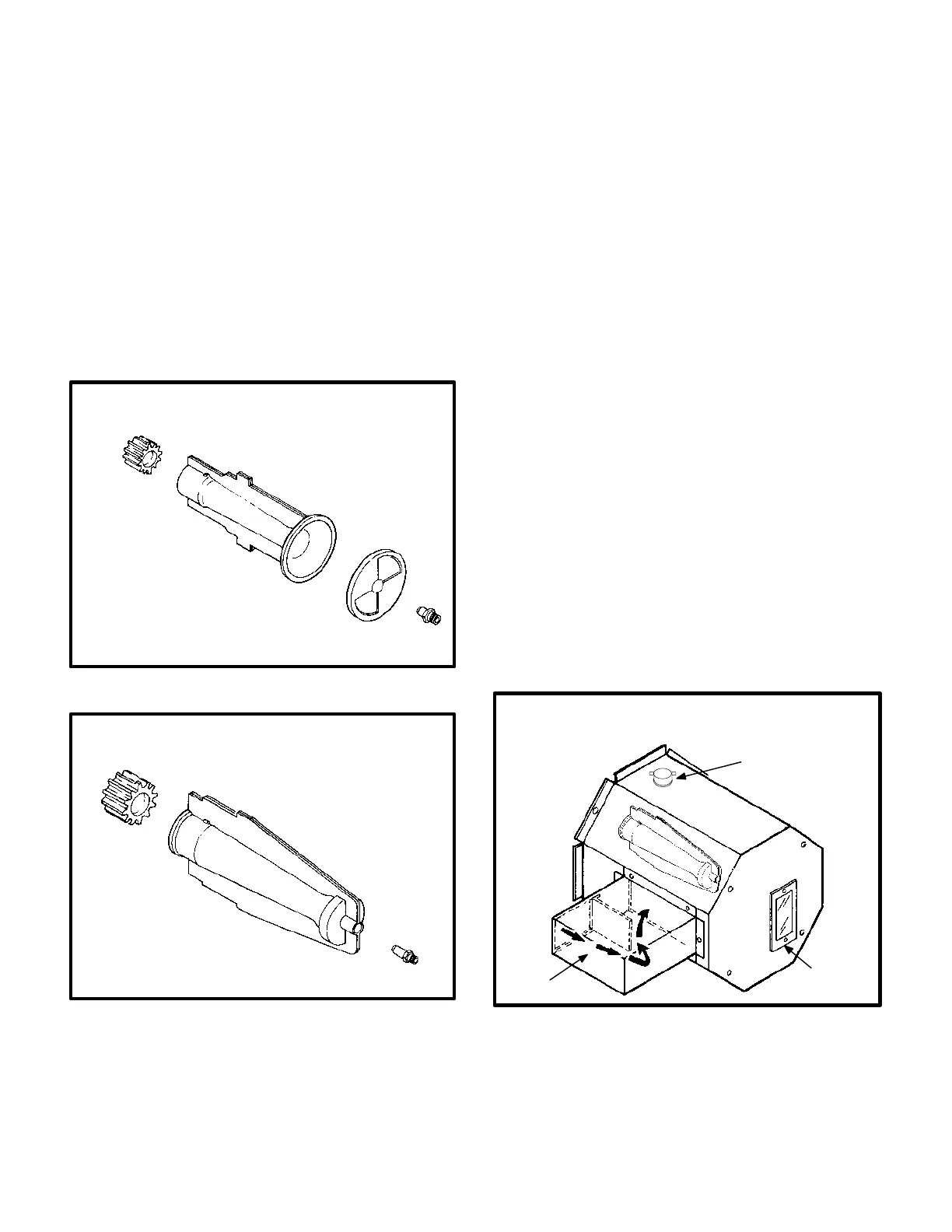

INSHOT BURNER

100,000 and 125,000 Btuh HEAT EXCHANG

ERS

FIGURE 11

FLAME

RETENTION

RING

BURNER

ORIFICE

b-Orifice

All GCS16 units use an orifice which is precisely matched

to the burner input. The burner is supported by the orifice

and will easily slide off for service.

Each orifice and burner are sized specifically to the unit.

Refer to Lennox Repair Parts Listing for correct sizing in

formation.

3-Burner Enclosure

The following units are equipped with a burner enclosure

surrounding the burner assembly:

GCS16R-510-125, GCS16-510-125,

GCS16R-650-125, GCS16-650-125,

GCS16R-411-100, & GCS16H-311-75.

The enclosure is used to reduce sound levels in the burner

area. The enclosure consists of a metal wrapper sur

rounding the burner assembly and a glass flame viewing

window (see figure 12).

The burner can be inspected and the spark/sensor elec

trode removed by removing the burner enclosure sight

glass plate. If the burner must be removed or the orifice

accessed, the burner enclosure must be removed. Burner

enclosure and burner removal is detailed in the mainte

nance section of this manual.

Units equipped with burner enclosure are also equipped

with flame rollout switch. The switch provides unit protec

tion by shutting down the unit when flame rollout is sensed.

FIGURE 12

GCS16/GCS16R/GCS16H

BURNER ENCLOSURE

FLAME

ROLLOUT

SWITCH

SIGHT

GLASS

AIR INTAKE

Loading...

Loading...