Page 47

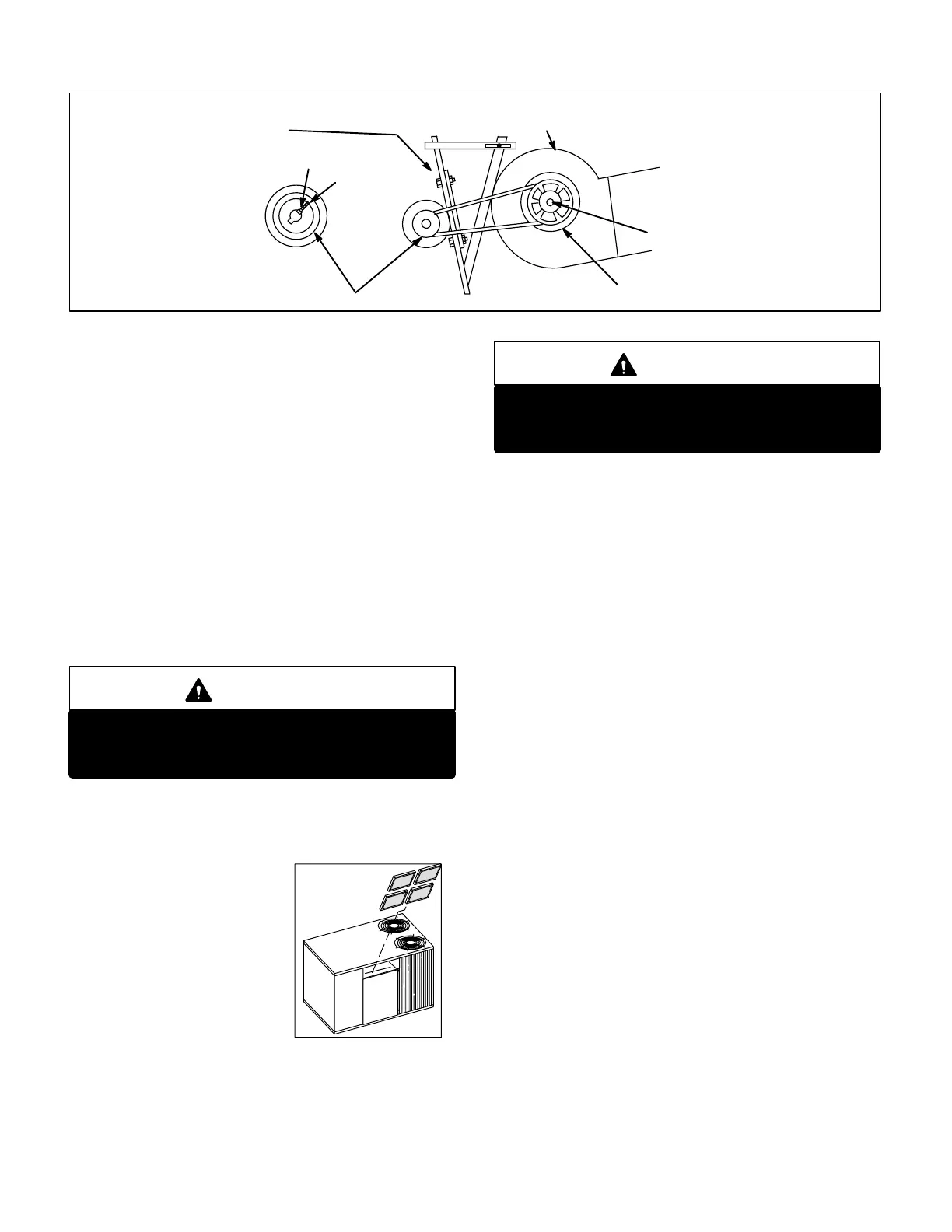

FIGURE 44

BLOWER SPEED ADJUSTMENT

BLOWER PULLEY

MOTOR PULLEY

SET SCREW

KEY

BLOWER

TO INCREASE CFM

TURN PULLEY CLOCKWISE

TO DECREASE CFM

TURN PULLEY

COUNTERCLOCKWISE

TO INCREASE BELT TENSION

1 - Loosen 2 locking bolts.

2 - Pull motor mounting plate.

3 - Tighten motor mounting

plate so plate is vertical.

MOTOR

MOUNTING PLATE

MEASURE RPM HERE

Adjusting Unit CFM:

The CFM can be changed by using the following proce

dure:

1- Remove the blower belt.

2- Loosen the set screws on motor pulley and remove

key as shown in figure 44.

3- Turn pulley clockwise to increase CFM and counter

clockwise to decrease CFM. One half turn changes

blower speed approximately 20 RPM.

NOTE-The pulley is factory set at three turns open.

4- Replace the key and tighten the set screw. Replace

and tighten the blower belt.

IX-MAINTENANCE

CAUTION

Electrical shock hazard. Turn off power to unit be

fore performing any maintenance, cleaning or

service operation on the unit.

A-Filters (Figure 45)

GCS16 unit is equipped with four pleated 2" throw-away

type filters. Permanent 1" foam filters are acceptable re

placements. Filters should

be checked monthly (or more

frequently in severe use) and

cleaned or replaced regular

ly. If permanent foam filters

are used as a replacement,

they should be checked and

cleaned periodically with

warm water and a mild deter

gent. Take note of the AIR

FLOW DIRECTION" mark

ing on the filter frame when re-installing.

NOTE-Filters must be U.L.C. certified or equivalent for

use in Canada.

CAUTION

Be careful when servicing unit to avoid accidental

contact with sharp metallic edges which may

cause personal injury.

B-Lubrication

All motors used in GCS16 units are prelubricated; no fur

ther lubrication is required.

C-Supply Air Blower Wheel

Annually inspect supply air blower wheel for accumulated

dirt or dust. Turn off power before attempting to remove ac

cess panel or to clean blower wheel.

D-Evaporator Coil

Inspect and clean coil at beginning of each season. Clean

using mild detergent or commercial coil cleanser. Check

condensate drain pan and line, if necessary. Flush coil and

condensate drain with water taking care not to get insula

tion, filters, return air ducts wet. Check connecting lines and

coil for evidence of oil leaks.

E-Condenser Coil

Clean condenser coil annually with detergent or commer

cial coil cleaner and inspect monthly during the cooling

season. Check connecting lines and coil for evidence of oil

leaks.

Condenser coils are made of individual coil slabs. Dirt and

debris may become trapped between the slabs. To clean

between slabs, carefully separate slabs and wash thor

oughly.

NOTE-If owner complains of insufficient cooling, refrig

erant charge should be checked. Refer to Charging

section in this manual.

F-Electrical

1- Check all wiring for loose connections.

2- Check for correct voltage at unit (unit operating).

3- Check amp-draw on both condenser fan motor and

blower motor.

Fan Motor Rating Plate ____ Actual ________

Indoor Blower Motor Rating Plate____ Actual____

GCS16-1853

AIR FILTERS

FIGURE 45

Loading...

Loading...