Page 27

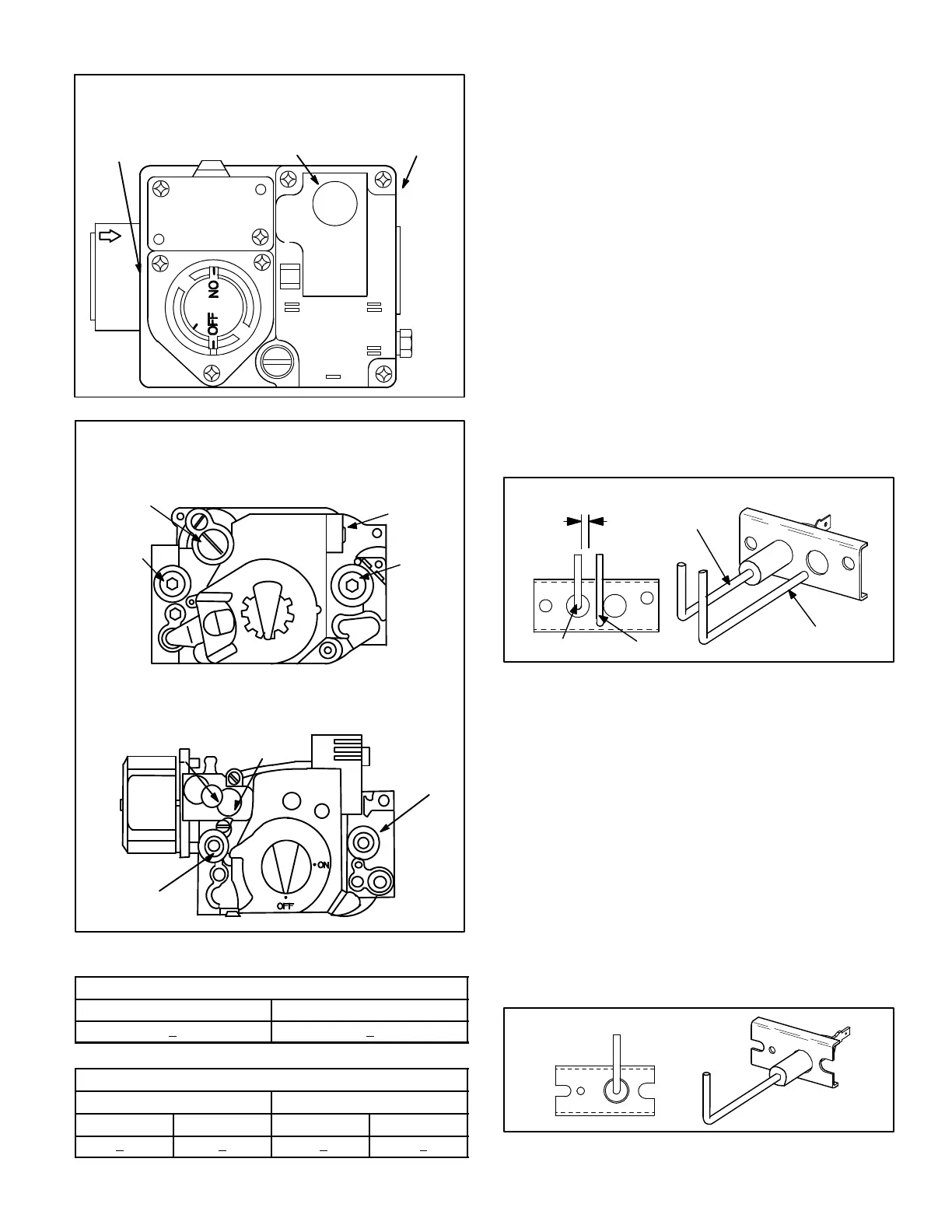

FIGURE 20

WHITE-RODGERS 36C76 GAS VALVE

TWO STAGE

D-1

GV-1

C-1

C2

GV-2

MANIFOLD

PRESSURE

TAP (SIDE)

STAGE 2 MANUAL MANIFOLD

PRESSURE ADJUSTMENT

SCREW UNDER CAP

INLET

PRESSURE

TAP (SIDE)

GAS VALVE SHOWN

IN “OFF” POSITION

GAS VALVE SHOWN

IN “OFF” POSITION

FIGURE 21

HONEYWELL VR8205 GAS VALVE

SINGLE STAGE

ON

OFF

PRESSURE

REGULATOR

INLET

PRESSURE

TAP

WIRING

TERMINALS

LOW FIRE

ADJUSTMENT

HIGH FIRE

ADJUSTMENT

INLET

PRESSURE

TAP

MANIFOLD

PRESSURE

TAP

HONEYWELL VR8305/VR8205 GAS VALVE

TWO STAGE

MANIFOLD

PRESSURE

TAP

GAS VALVE SHOWN

IN “OFF” POSITION

GAS VALVE SHOWN

IN “OFF” POSITION

TABLE 5

SINGLE STAGE GAS VALVE FACTORY SETTING

Natural (inlet-5.5” to 10.5”) L.P (inlet-11.0” to 13.0”)

3.5” + 0.3” 10.5” + 0.3”

TABLE 6

TWO STAGE GAS VALVE FACTORY SETTING

Natural (inlet-5.5” to 10.0”) L.P. (11.0” to 13.0”)

High Fire Low Fire High Fire Low Fire

3.7”+ 0.3” 1.9” + 0.2 10.5”+ 0.3 5.32” + 0.2

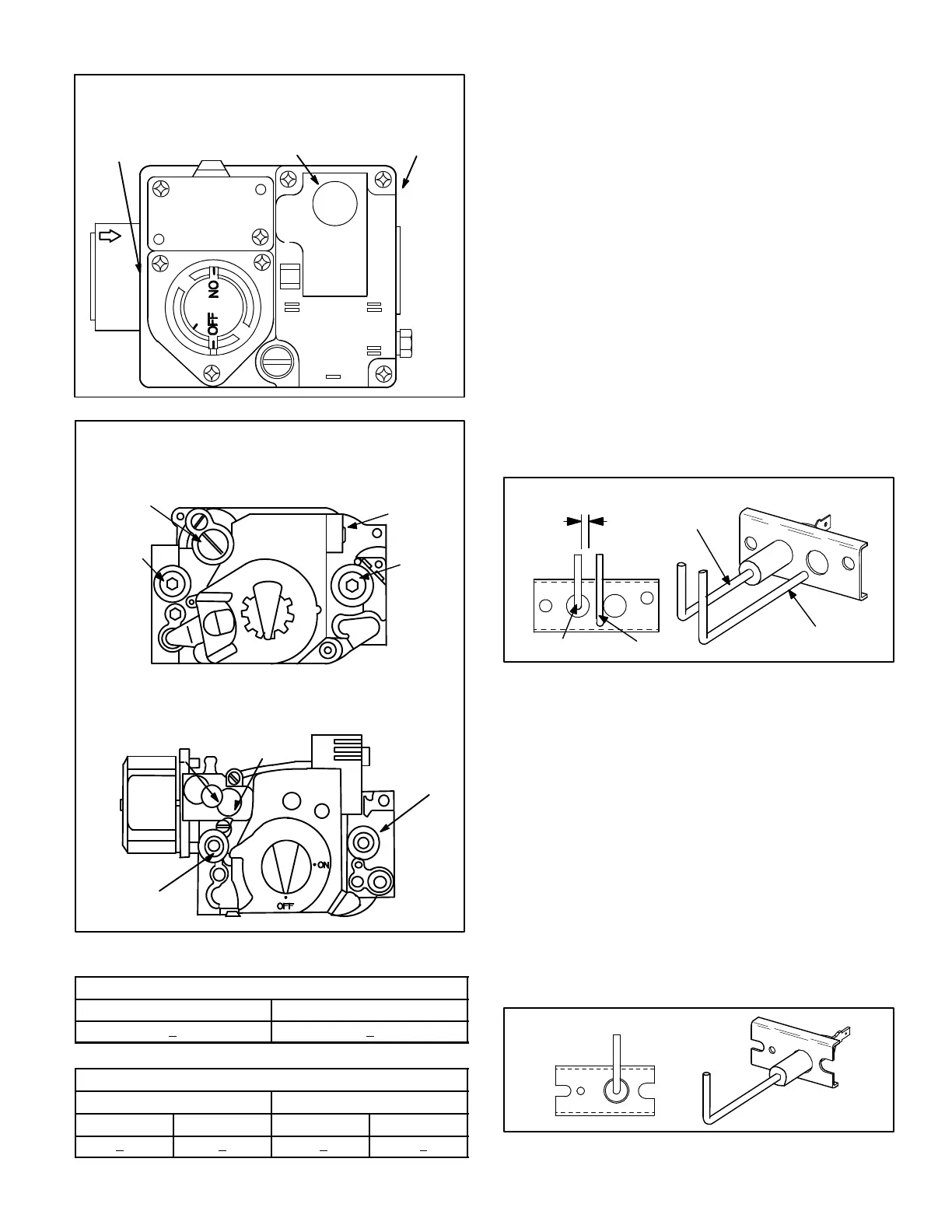

11-Spark Electrodes

An electrode assembly is used for ignition spark. The

electrode is mounted throughholes on the left-most end

of the burner support. The electrode tip protrudes into

theflame envelopeof the adjacent burner. The electrode as-

sembly is fastened to burner supports and canbe removedfor

service without removing any part of the burners.

During ignition, spark travels through the spark electrode (fig-

ure 22) and ignites the leftburner. Flame travels fromburner to

burner until all are lit.

The spark electrode is connected to the ignition control by a 8

mm silicone-insulated stranded high voltage wire. The wire

uses 1/4” (6.35 mm)female quick connect on the electrode

end and female spark plug-type terminal on the ignition control

end.

NOTE-IN ORDER TO MAXIMIZE SPARK ENERGY TO

ELECTRODE, HIGH VOLTAGE WIRE SHOULD TOUCH

UNIT CABINET AS LITTLE AS POSSIBLE.

GROUND

ELECTRODE

GROUNDELECTRODE

.125” ± .015”

(3.2 mm ± .4 mm)

FIGURE 22

12-Flame Sensors

Aflamesensor (figure23)islocated onthe right sideof the

burner support. The sensor is mounted through a hole in

the burner support and the tip protrudes into the flame enve-

lope of the right most burner. The sensor assembly is fastened

to burner supports and can be removed for service without re-

moving any part of the burners.

When flame is sensed by the flame sensor (indicated by

microamp signal through the flame) sparking stops imme-

diately. During operation, flame is sensed by current

passed along the ground electrode (located on the spark

electrode), through the flame and into the sensing elec-

trode. The ignition control allows the gas valve to stay

open as long as a flame signal (current passed through

the flame) is sensed.

SENSOR

FIGURE 23

Loading...

Loading...