Page 20

9-Power Exhaust Relay K65 & K231 (PED

units)

Power exhaust relays K65 and K231 are N.O. DPDT relays

with a 24VAC coil. The relay are used in units equipped with

the optional power exhaust dampers. K65 and K231 are

energized by the A55 Unit Controller, after the economizer

dampers reach 50% open (adjustable in ECTO). When K65

closes, exhaust fan B10 is energized and when K231 clos

es B11 is energized.

10-Variable Frequency Drive A96 (optional)

Staged-Blower units are equipped with a VFD which alters

the supply power frequency and voltage to the blower mo

tor. Blower speed is staged depending on the compressor

stages, heating demand, ventilation demand, or smoke

alarm. The amount of airflow for each stage is preset from

the factory. Airflow can be adjusted by changing ECTO pa

rameters in the A55 Unit Controller. The VFD is located be

low the Unit Controller.

11-VFD Power To Motor Contactor K202

(optional)

Contactor is used in Staged-Blower units equipped with a

VFD bypass option. The three‐pole 40 amp contactor with a

24VAC coil is energized by the A55 Unit Controller. K202 al

lows power from the VFD to the B3 blower motor in response

to blower demand.

12-Inverter Start Forward Rotation Relay K203

(optional)

Relay is used in optional Staged-Blower units and is a

three-pole double-throw relay with a 24VAC coil. K203 is

energized by the A55 Unit Controller and provides input to

the A96 VFD to start blower forward rotation. K203 also de-

energizes K3 allowing A96 to control B3 blower.

13-Unit Controller A55

The Unit Controller provides all unit control functions, unit

status information, unit diagnostics, programmable pa

rameters and USB verification and profile sharing. Refer

to the Unit Controller guide provided with the unit. Thermo

stat wires are connected to J297 on the Unit Controller.

14-Compressor 3 & 4 Controller A59 & A178

The compressor 3 & 4 control module A59 controls two ad

ditional compressor stages. A59 includes all inputs and

outputs required for compressor and fan control, compres

sor stage diagnostics and low ambient control.

The M3 unit controller is only compatible with L-Connection

sensors provided with the unit or purchased separately as

specified in the Product Specification. Tables 1 through 4

show thermistor and pressure transducer readings.

Temperature Sensors

The return air (RT16) and discharge air (RT6) duct probes

and the outdoor air (RT17) are all two wire thermistors. The

resistance vs. temperature table is shown below:

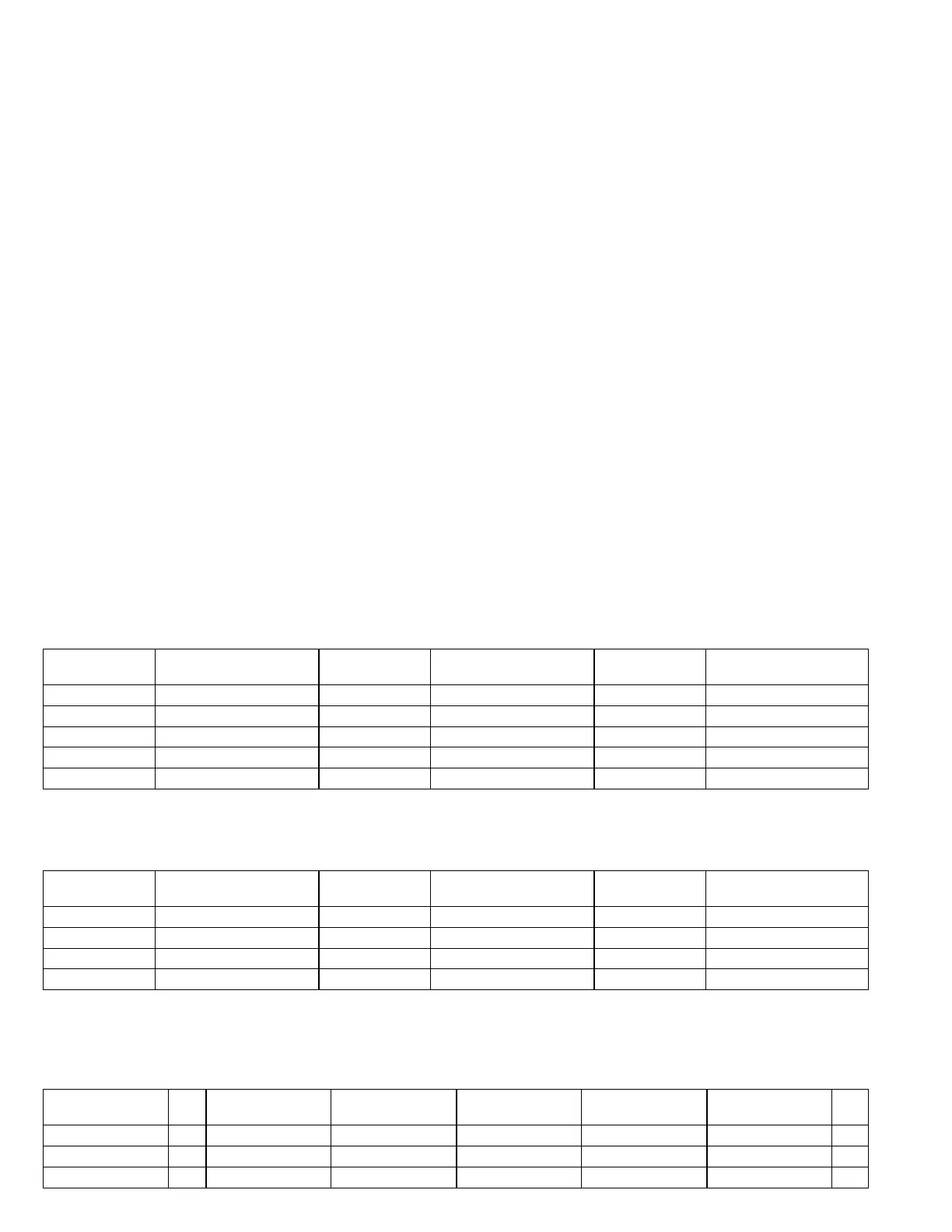

Table 1

Resistance vs. Temperature

Temp. °F (°C) Resistance +/-2%

Temperature °F

(°C)

Resistance +/-2% Temp. °F (°C) Resistance +/-2%

-40 (-40) 335,671 40 (4.4) 26,106 90 (32.2) 7,332

-20 (-28.9) 164,959 50 (10) 19,904 100 (37.8) 5,826

0 (-17.8) 85,323 60 (15.6) 15,313 120 (48.9) 3,756

20 (-6.7) 46,218 70 (21.1) 11,884 130 (54.4) 3,047

30 (-1.1) 34,566 80 (26.7) 9,298

Room Sensors

Room sensor (A2) is a two-wire thermistor with 1k series resistor.

Table 2

Two-Wire Thermistor

Temp. °F (°C) Resistance +/-2%

Temperature °F

(°C)

Resistance +/-2% Temp. °F (°C) Resistance +/-2%

40 (4.4) 27,102 60 (15.6) 16,313 80 (26.7) 10,299

45 (7.2) 23,764 65 (18.3) 14,474 85 (29.4) 9,249

50 (10) 20,898 70 (21.1) 12,882 90 (32.2) 8,529

55 (12.8) 18,433 75 (23.9) 11,498

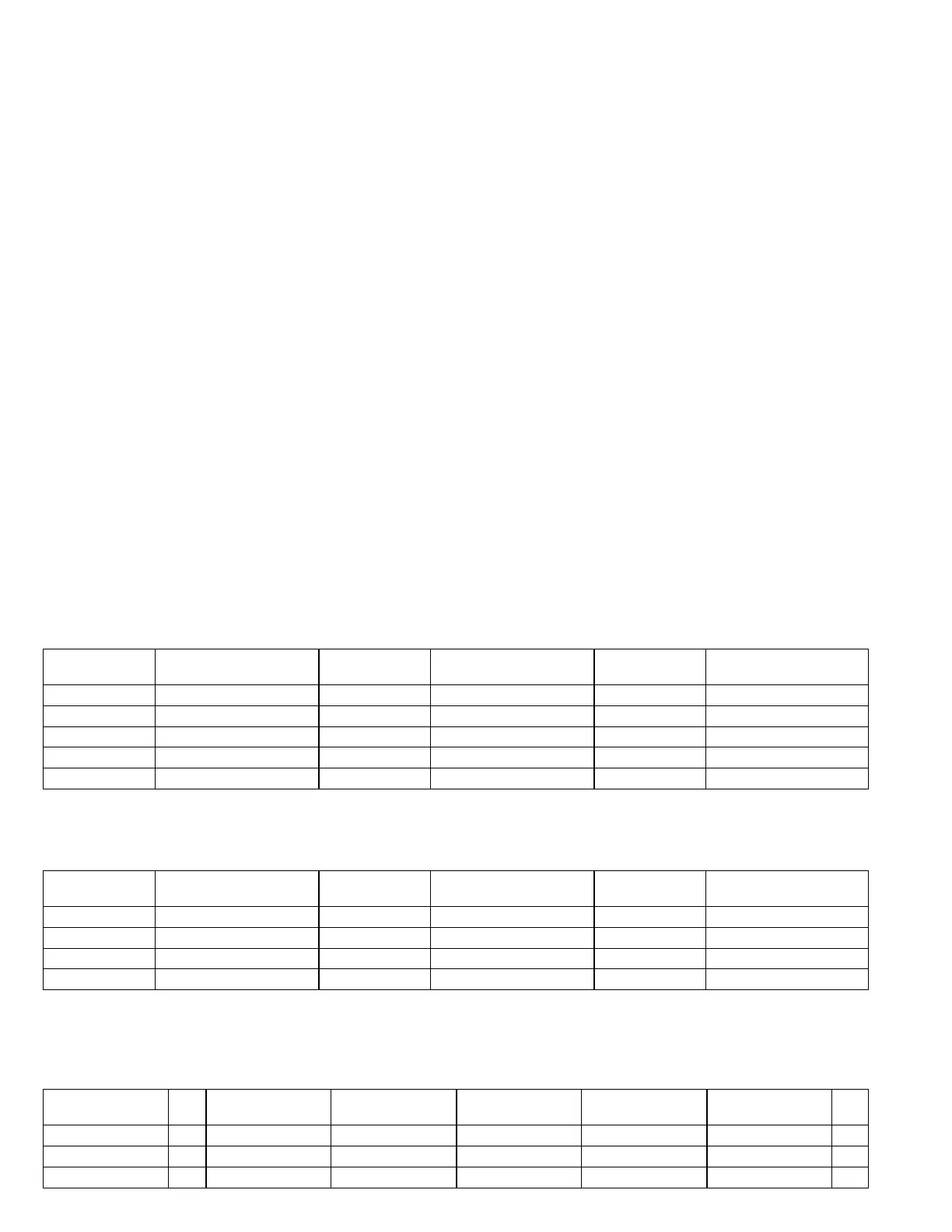

Carbon Dioxide Sensor

The indoor carbon dioxide sensor (A63) is an analog sensor with a 0-10VDC output over a carbon dioxide range of 0-2000

ppm as shown in the following table. The sensor is powered with 24VAC.

Table 3

Carbon Dioxide Range

Carbon Dioxide

PPM

DC

V

Carbon Dioxide

PPM

DC Voltage

Carbon Dioxide

PPM

DC Voltage

Carbon Dioxide

PPM

DC

V

0 0 600 3 1200 6 1800 9

200 1 800 4 1400 7 2000 10

400 2 1000 5 1600 8

Loading...

Loading...