Page 36

VI-ACCESSORIES

The accessories section describes the application of most of

the optional accessories which can be factory or field installed

to the LCM units.

A-Roof Curbs

When installing the LCM units on a combustible surface

for downflow discharge applications, the hybrid

C1CURB70C-1 8-in height, C1CURB71C-1 14-in height,

C1CURB72C-01 18-in height and C1CURB73C-1 24-in

roof mounting frame is used. The assembled hybribd

mounting frame is shown in figure 17. Refer to the roof

mounting frame installation instructions for details of proper

assembly and mounting. The roof mounting frame MUST

be squared to the roof and level before mounting. Plenum

system MUST be installed before the unit is set on the

mounting frame. Typical roof curbing and flashing is shown

in figure 18. Refer to the roof mounting frame installation in

structions for proper plenum construction and attachment.

For horizontal discharge applications, use the standard

C1URB14C-1 26-in or C1CURB16C-1 37‐in height roof

mounting frame. This frame converts unit from down‐flow

to horizontal air flow. The 37 inch horizontal frame meets

National Roofing Code requirements. The roof mounting

frames are recommended in all other applications but not

required. If the LCM units are not mounted on a flat (roof)

surface, they MUST be supported under all edges and un

der the middle of the unit to prevent sagging. The units

MUST be mounted level within 1/16” per linear foot or

5mm per meter in any direction.

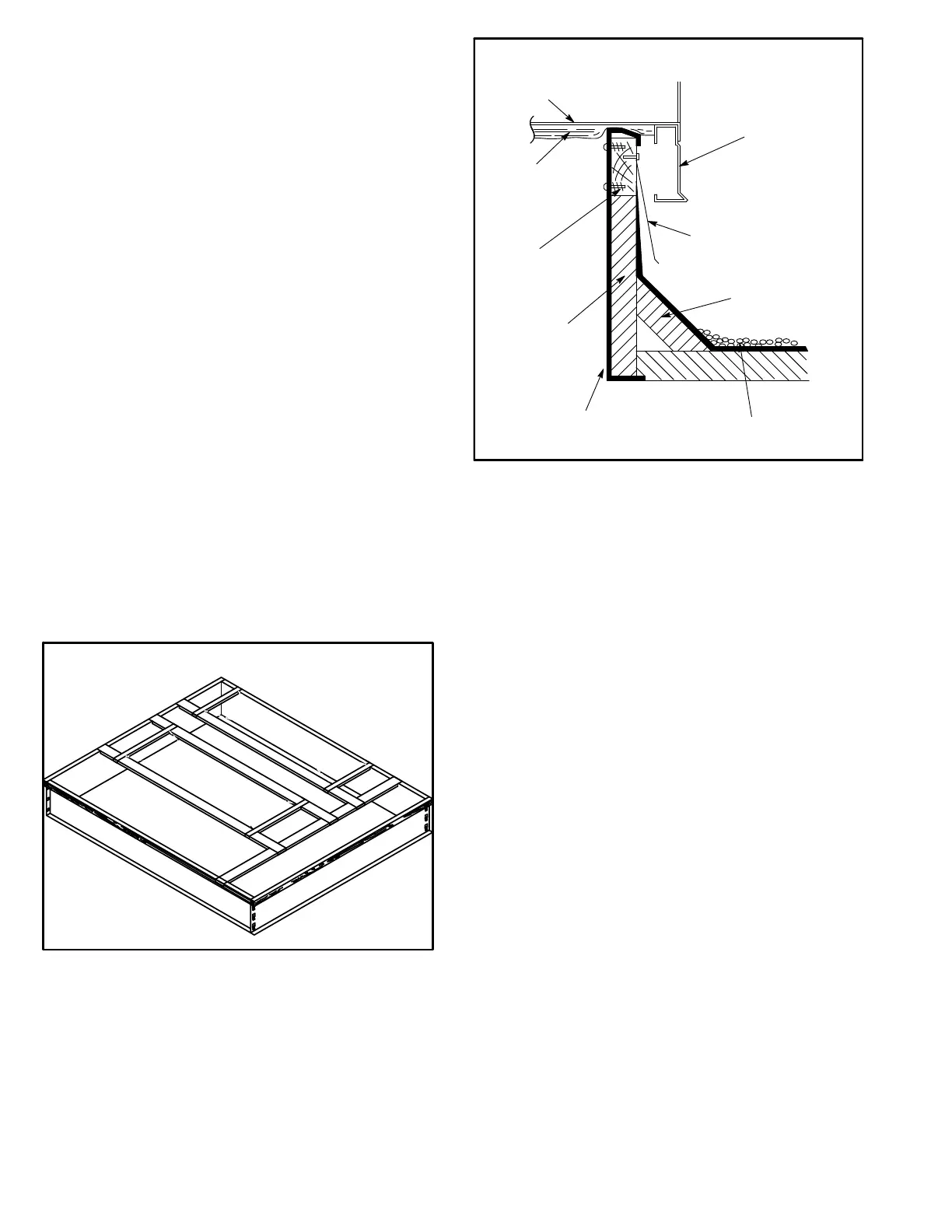

FIGURE 17

ASSEMBLED HYBRIDROOF CURB

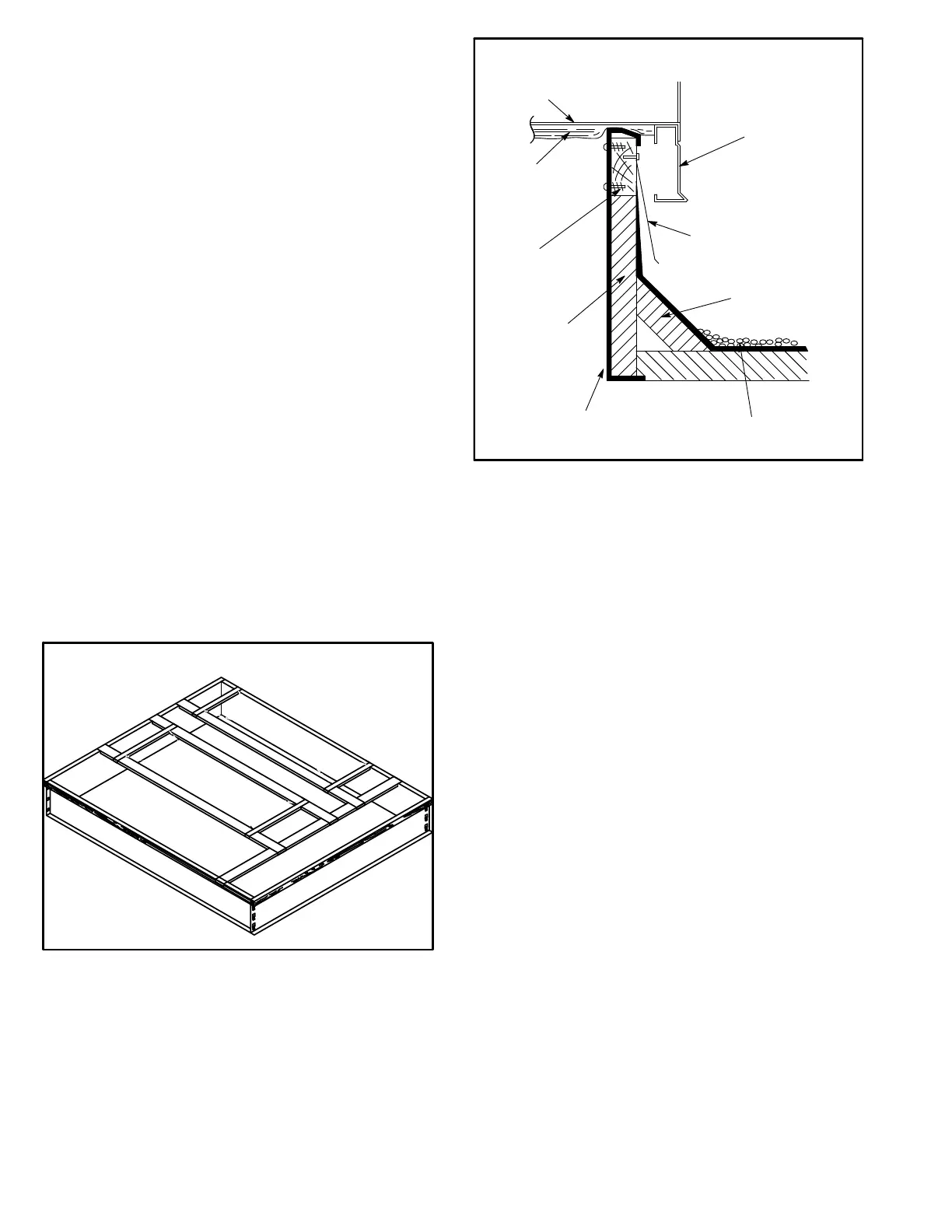

FIGURE 18

ROOF

MOUNTING FRAME

(Extends around entire

perimeter of unit)

FIBERGLASS

INSULATION

(Furnished)

COUNTER FLASHING

(Field Supplied)

UNIT BASE

BOTTOM

RIGID INSULATION

(Field Supplied)

ROOFING

MATERIAL

CANT STRIP

(Field Supplied)

NAILER STRIP

(Furnished)

UNIT BASE

RAIL

TYPICAL FLASHING DETAIL

B-Transitions

Optional supply/return transitions C1DIFF33C-1 and

C1DIFF34C-1 are available for use with LCM series units

utilizing optional C1CURB roof curbs. Transition must be

installed in the roof curb before mounting the unit to the

frame. Refer to the manufacturer's instructions included

with the transition for detailed installation procedures.

C-C1DAMP10 & E1DAMP20 Outdoor Air

Dampers

C1DAMP10C and E1DAMP20C (figure 19) consist of a set

of dampers which may be manually or motor operated to al

low up to 25 percent outside air into the system at all times

(see figure 19). Either air damper can be installed in LCM

units. Washable filter supplied with the outdoor air dampers

can be cleaned with water and a mild detergent. It should be

sprayed with Filter Handicoater when dry prior to reinstalla

tion. Filter Handicoater is R.P. Products coating no. 418 and

is available as Part No. P-8-5069.

Loading...

Loading...