Page 29

LGT/LCT036, 048, 060, 072

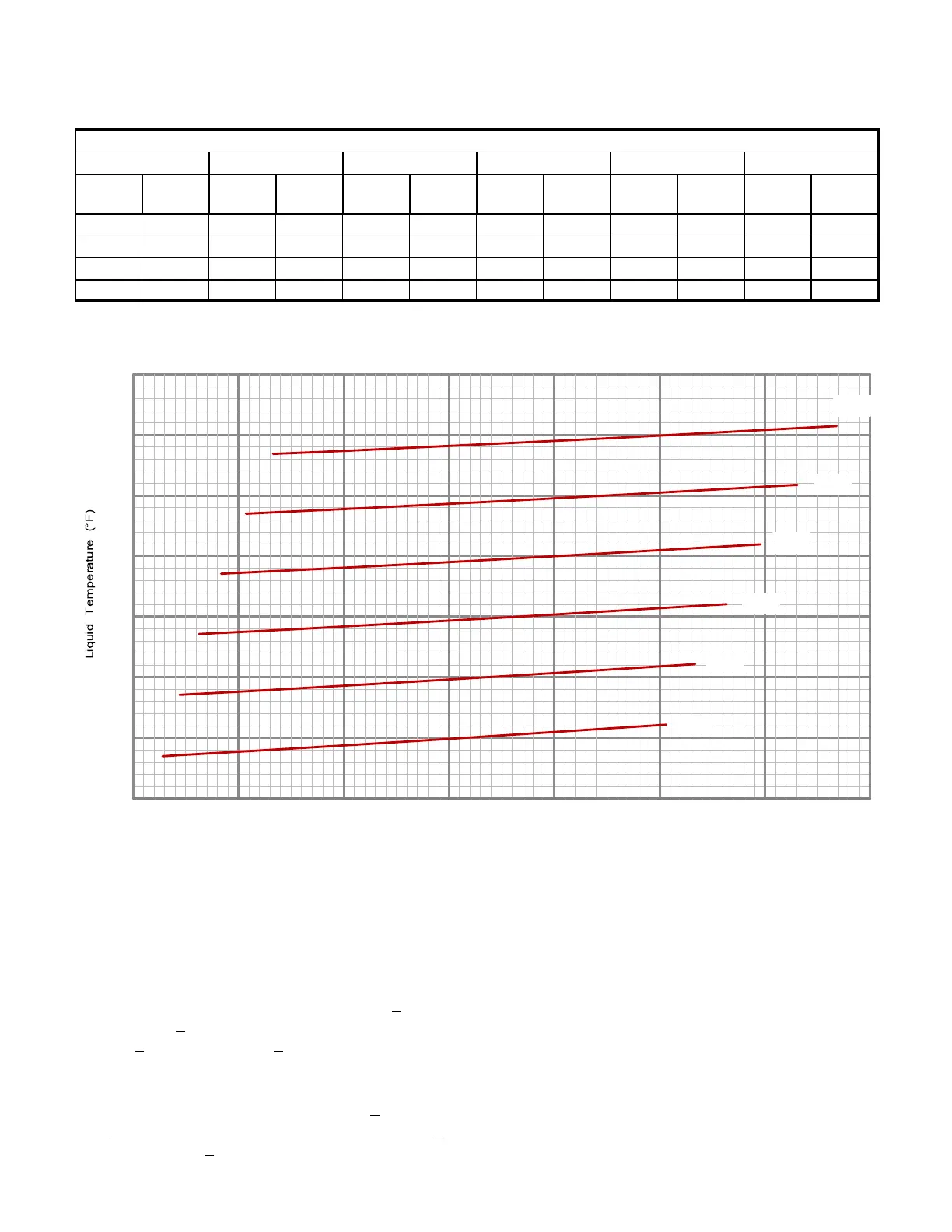

TABLE 12

072 NORMAL OPERATING PRESSURES - REHEAT - ALL-ALUMINUM COIL - 581111-01

Outdoor Coil Entering Air Temperature

65 F 75 F 85 F 95 F 105 F 115 F

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

108 276 109 316 111 363 113 418 116 480 118 550

116 281 118 320 120 367 123 422 125 484 128 554

135 294 137 332 140 379 143 432 146 494 149 563

156 310 158 348 161 394 165 447 168 508 172 576

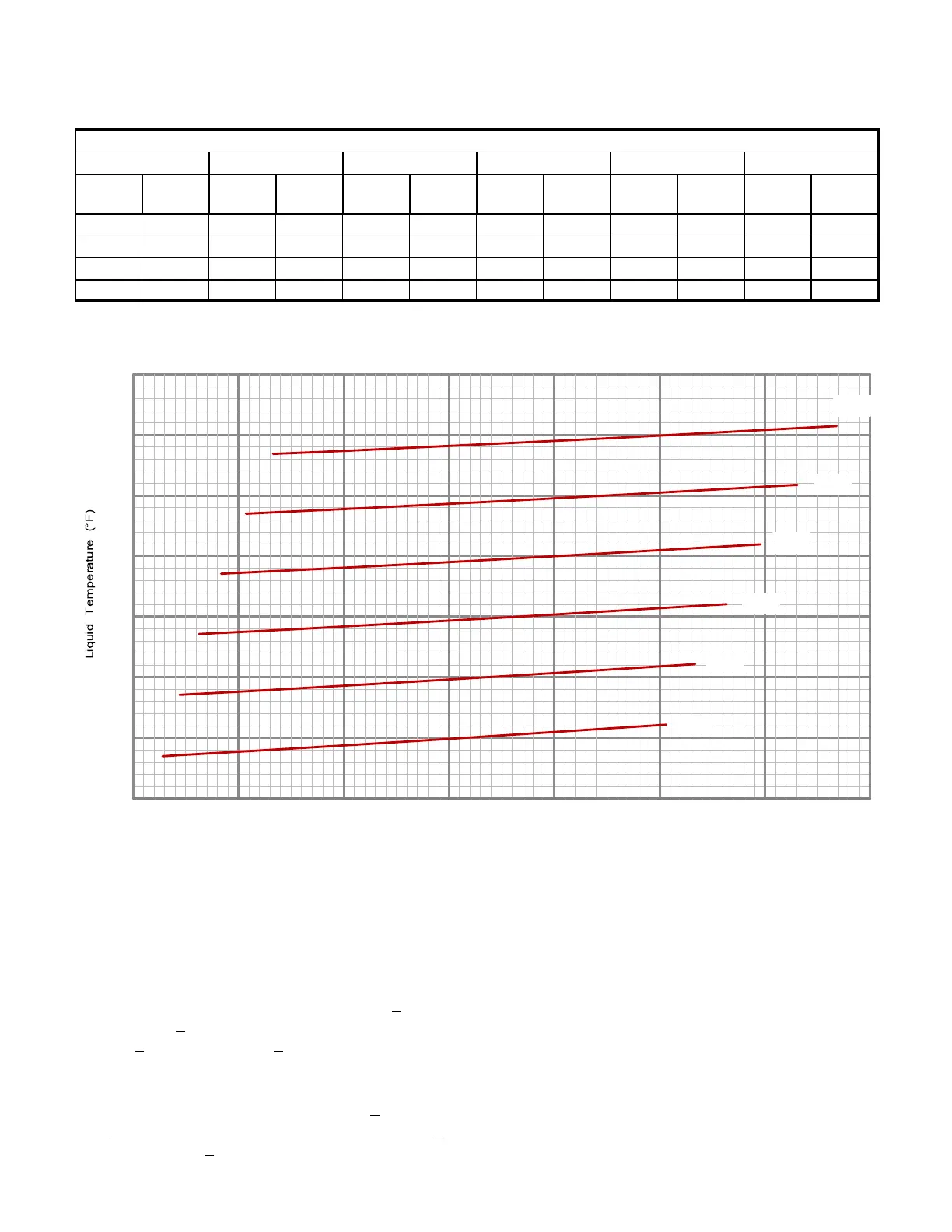

072 CHARGING CURVE - REHEAT - ALL-ALUMINUM COIL - 581111-01

Suction Pressure (psig)

70

80

90

100

110

120

105 115 125 135 145 155

Outdoor Temperature (°F)

165 175

105°

95°

115°

85°

75°

65°

60

130

C-Compressor Controls

See unit wiring diagram to determine which controls are

used on each unit. Optional controls are identified on

wiring diagrams by arrows at junction points.

1- High Pressure Switch (S4)

The compressor circuit is protected by a high

pressure switch which opens at 640 psig +

10 psig

(4413 kPa +

70 kPa) and automatically resets at 475

psig +

20 psig (3275kPa + 138 kPa).

2- Low Pressure Switch (S87)

The compressor circuit is protected by a loss of

charge switch. Switch opens at 40 psig +

5 psig (276

+

34 kPa) and automatically resets at 90 psig + 5

psig (621 kPa + 34 kPa).

3- Diagnostics Sensors (RT46, RT48)

Two thermistors are located on specific points in the

refrigeration circuit. The thermistors provide constant

temperature feedback to the Unit Controller to protect

the compressor. Thermistors take the place of the

freezestat and low ambient pressure switch.

4- Compressor Crankcase Heater (HR1)

Crankcase heater must be energized at all times to

prevent compressor damage due to refrigerant

migration. Energize crankcase heater 24 hours before

unit start-up by setting thermostat so that there is no

cooling demand (to prevent compressor from cycling)

and apply power to unit.

Loading...

Loading...