Page 35

Field-Installed Accessories

When field-installing the following accessories, refer to

the latest online installation instruction.

TABLE 12

Accessory

Instruction #

Economizer 507227-XX

Outdoor Air Damper 506340-XX

Electric Heat 507250-XX

Smoke Detector 506437-XX

Factory Unit Controller Settings

Use the mobile service app to adjust parameters; menu

paths are shown in each table. Refer to the Unit Controller

manual provided with each unit.

Tables 13 through 16 show blower factory settings.

Record any field-adjusted settings in the blank column.

Tables 17 and 18 show control options. When applicable,

record field-specific information on the label located

inside the compressor access panel.

When field installing optional kits and accessories, the

Unit Controller must be configured to identify the option

before it will function. Refer to figures 36 and 37 to

determine whether the Unit Controller configuration I.D.

must change. To configure the option, use RTU MENU >

SETUP > INSTALL menu path. Press NEXT until

CONFIGURATION ID 1 or 2 appears depending on the

option installed. Change the appropriate character in the

configuration I.D. For example, when an economizer is

installed using a single enthalpy sensor, change

configuration I.D. 1, the second character, to “S”.

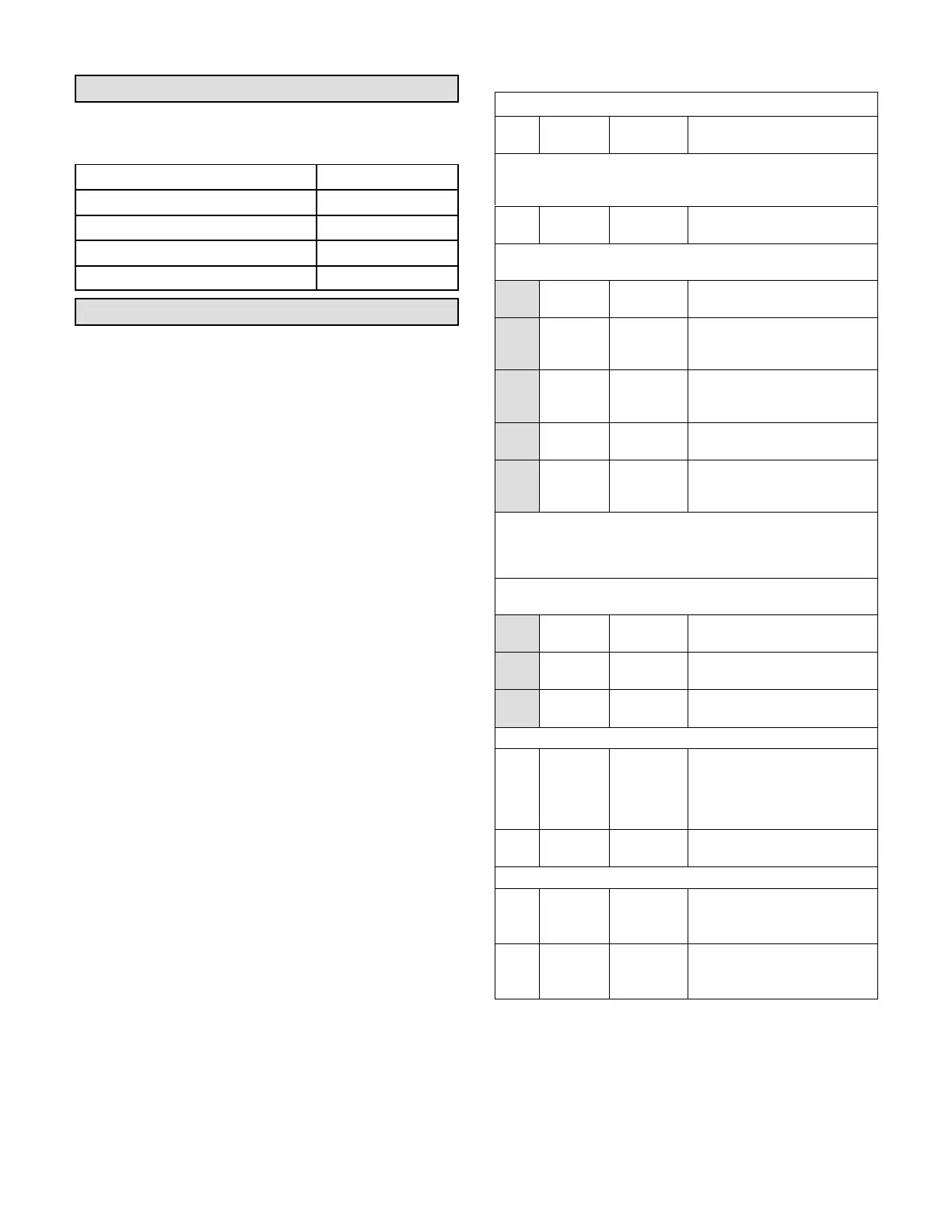

TABLE 13

LDT/LHT 092 (2-Compressor) Staged Direct Drive

Para

mete

r

Factory

Setting

Field

Setting

Description

Note: Any changes to Smoke CFM setting must be adjusted be

fore the other CFM settings. Use SETTINGS > RTU OPTIONS >

EDIT PARAMETERS

12

3000

CFM

CFM

Blower CFM during smoke

detection.

SETUP > TEST & BALANCE (can also use SETTINGS > RTU

OPTIONS > BLOWER > SPEEDS)

3000

CFM

CFM

Blower CFM during heating.

2625

CFM

CFM

Blower CFM during high speed

cooling (2 compressor)

operation.

800

CFM

CFM

Blower CFM during low speed

cooling (1 compressor)

operation.

800

CFM

CFM

Blower CFM during ventilation.

1195

RPM

RPM*

Adjust RPM based on unit static

and blower tables to reach tar

get CFM.

*Once all four blower settings are entered, the target (highest of the

heating and cooling settings) CFM will be displayed. Once the RPM

is saved for the target CFM, all other blower RPM values are set by

the Unit Controller according to the field CFM setting..

SETUP > TEST & BALANCE (can also use SETTINGS > RTU

OPTIONS > DAMPER)

0% %

Damper min. position during

LOW blower operation.

0% %

Damper min. position during

HIGH blower operation.

50% %

Min. Damper % for stage 1

power exhaust operation.

SETTINGS > RTU OPTIONS > EDIT PARAMETERS

29 101% %Open

Damper minimum position during

G blower operation. (Setting para

meter 29 to “101” disables para

meter 29 and passes control to

parameter 9 or 132)

216 10% %

Deadband % for stage 1 power

exhaust operation.

SETTINGS > RTU OPTIONS > EDIT PARAMETER

85 0°F °F

Compressor 1 low temp lockout.

Settings lower than 0°F could

void warranty.

86 0°F °F

Compressor 2 low temp lockout.

Settings lower than 0°F could

void warranty.

Loading...

Loading...