Page 34

ELECTRIC HEAT CONTROL SECTION

(45 − 120 kW electric heat only)

17−Electric Heat Relay K9

All LCA/LCC series units with 45 − 120 kW electric heat use an

electric heat relay K9. K9 is a N.O. SPST pilot relay intended to

electrically isolate the unit’s 24V circuit from the electric heat

24V circuit. K9 is energized by the main control board A55.

K9−1 closes, enabling T2 to energize the electric heat con-

trol panel A60 and contactors K17 and K18.

18−Electric Heat Transformer T2

All LCA/LCC series units with 45 − 120 kW electric heat

use a single line voltage to 24VAC transformer mounted

in the electric heat control hat section in the control box.

The transformer supplies power to all electric heat con-

trols (contactors and coils). The transformer is rated at

70VA and is protected by a 3.5 amp circuit breaker CB13.

The 208/230 (Y) voltage transformers use two primary

voltage taps as shown in figure 4. Transformer T2 is iden-

tical to T1.

INTEGRATED MODULAR CONTROL BOARDS

The Integrated Modular Control (IMC) is a series of control

boards which integrates most control functions required for the

LGA/LGC/LCA/LCC units. The control boards are located in

the upper left hand corner of the control box. The control

includes complete unit diagnostics with permanent code

storage, field programmable control parameters and

control options, on-site testing, and serial communica-

tions. Seven different printed circuit boards (see figure 7)

make-up the modular configurations for the LGA/LGC/

LCA/LCC units. See table 1 for a list of control panels

used for each unit. See figure 7 for control location. For fur-

ther information refer to Integrated Modular Control Guide sent

with each unit.

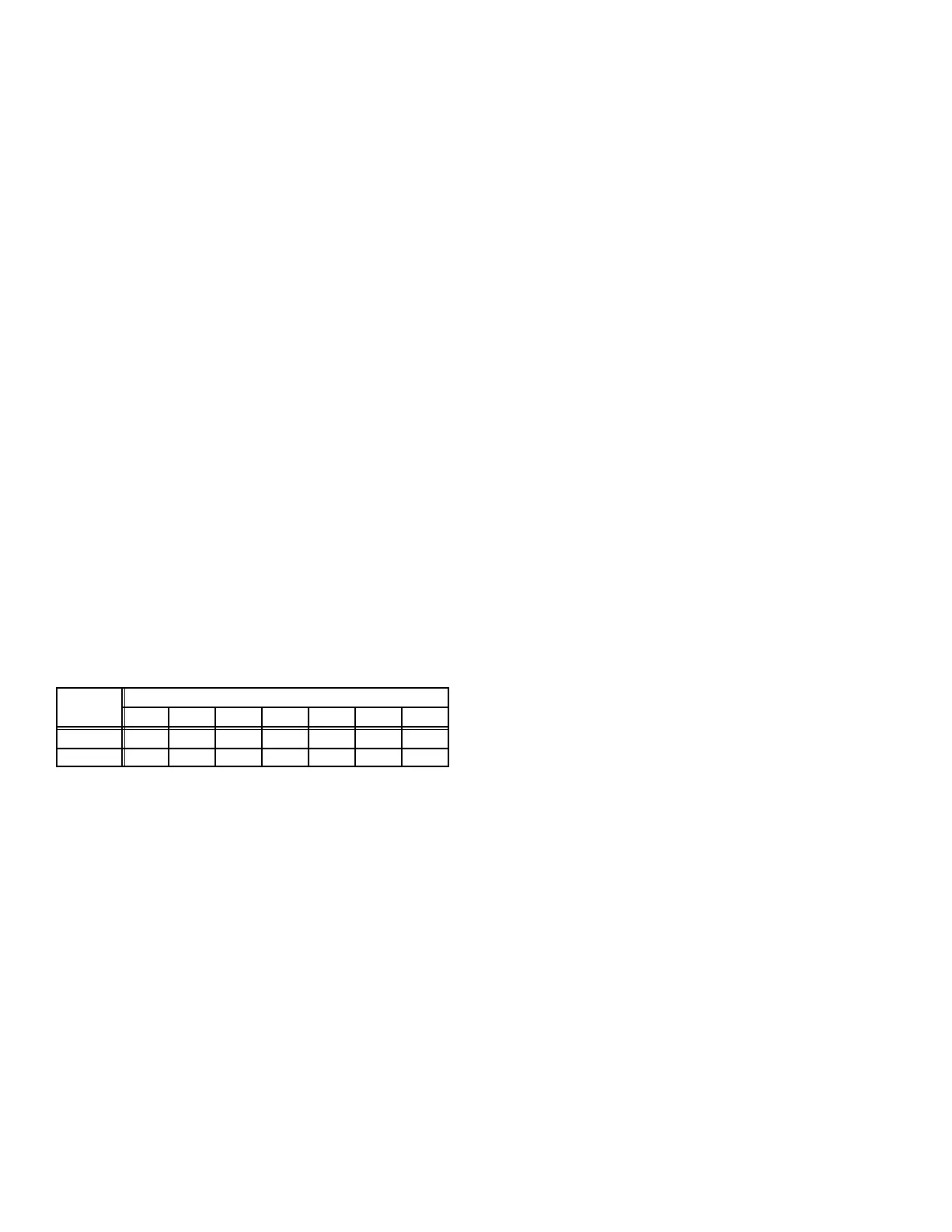

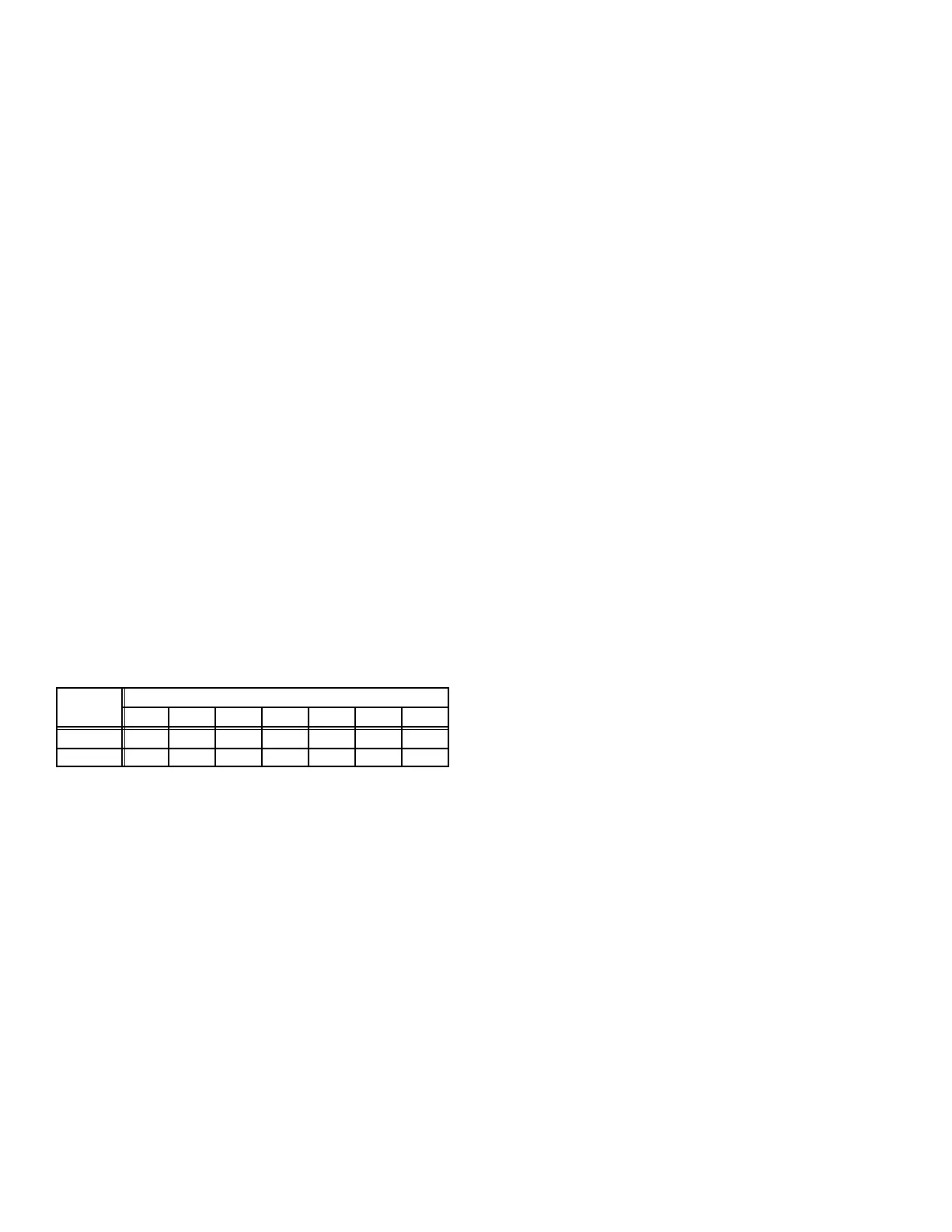

TABLE 1

UNIT

CONTROL PANELS

A55 A57 A59 A58 A60 A61 A56

LGA/LGC X X X X OPT

LCA/LCC X X X X OPT

19−Main Control Module A55 (all units)

The main control module A55 is the heart of the system. It

controls one compressor, one two-stage gas valve (first

stage), one bank of electric heat, one outdoor fan, and one

blower. A55 includes the thermostat inputs, serial commu-

nications ports, diagnostic code display, control pushbutton,

system configuration dip switches, and four expansion ports. A

diagnostic code list is located on the back side of the left ac-

cess panel.

20−Compressor 2 Control Module A57

(all units)

The compressor 2 control module A57 controls one addi-

tional compressor stage for the LGA/LGC/LCA/LCC units.

A57 includes all inputs and outputs required for compressor

and fan control, compressor stages diagnostics, and low

ambient control.

21−Compressor 3 & 4 Control Module

A59 (all units)

The compressor 3 & 4 control module A59 controls two addi-

tional compressor stages for the LGA/LGC/LCA/LCC units.

A59 includes all inputs and outputs required for compressor

and fan control, compressor stage diagnostics, and low ambi-

ent control.

22−Gas Valve Control Module A58

(LGA/LGC units)

The gas valve control module A58 controls an additional burn-

er with a two-stage gas valve. A58 includes all inputs and out-

puts required for control and diagnostics of one two-stage gas

valve burner (second stage).

23−Electric Heat Control Module A60

(LCA/LCC units if 45 − 120 kW

electric heat is used)

The electric heat control module A60 is used to control a

second electric heat bank. A60 is used on the LCA/LCC

units.

24−Economizer Control Module A56

(Economizer only)

The economizer control module A56 controls the econo-

mizer. A56 has four different cooling modes, sensible

temperature, outdoor enthalpy, differential enthalpy, and

global control.

Loading...

Loading...