Page 28

TABLE 7

GAS VALVE REGULATION FOR LGT UNITS

Max Inlet

Pressure

“W.C.

Operating Pressure “W.C.

(outlet) Factory Setting

Natural L.P. Propane

Low Low

1.6+ + + +

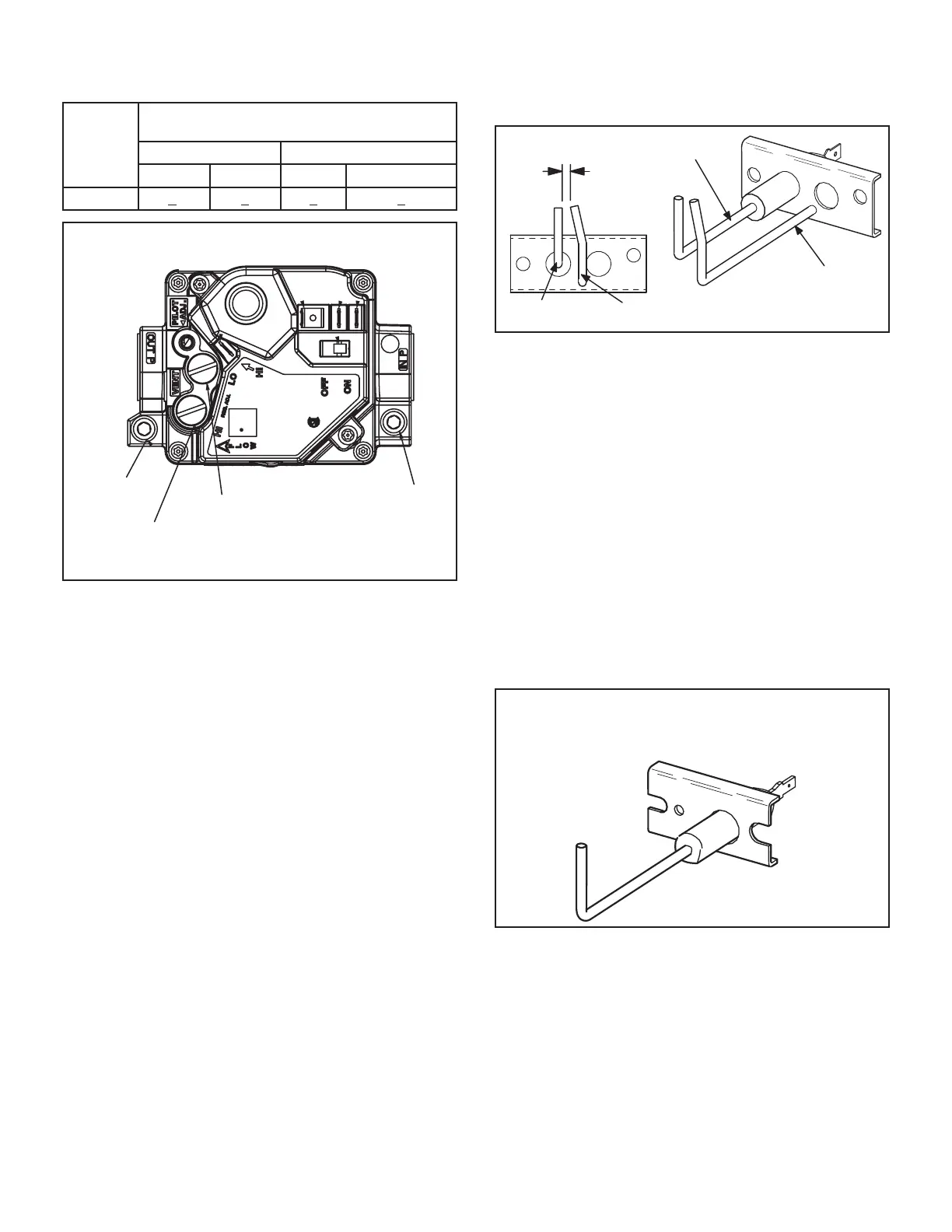

WHITE RODGERS 36H54 GAS VALVE

Two-Stage

GAS VALVE SWITCH SHOWN IN ON POSITION.

Inlet Pressure Tap

Outlet Pressure

Tap

High Fire Adjustment

(under cap)

Low Fire Adjustment

(under cap)

FIGURE 20

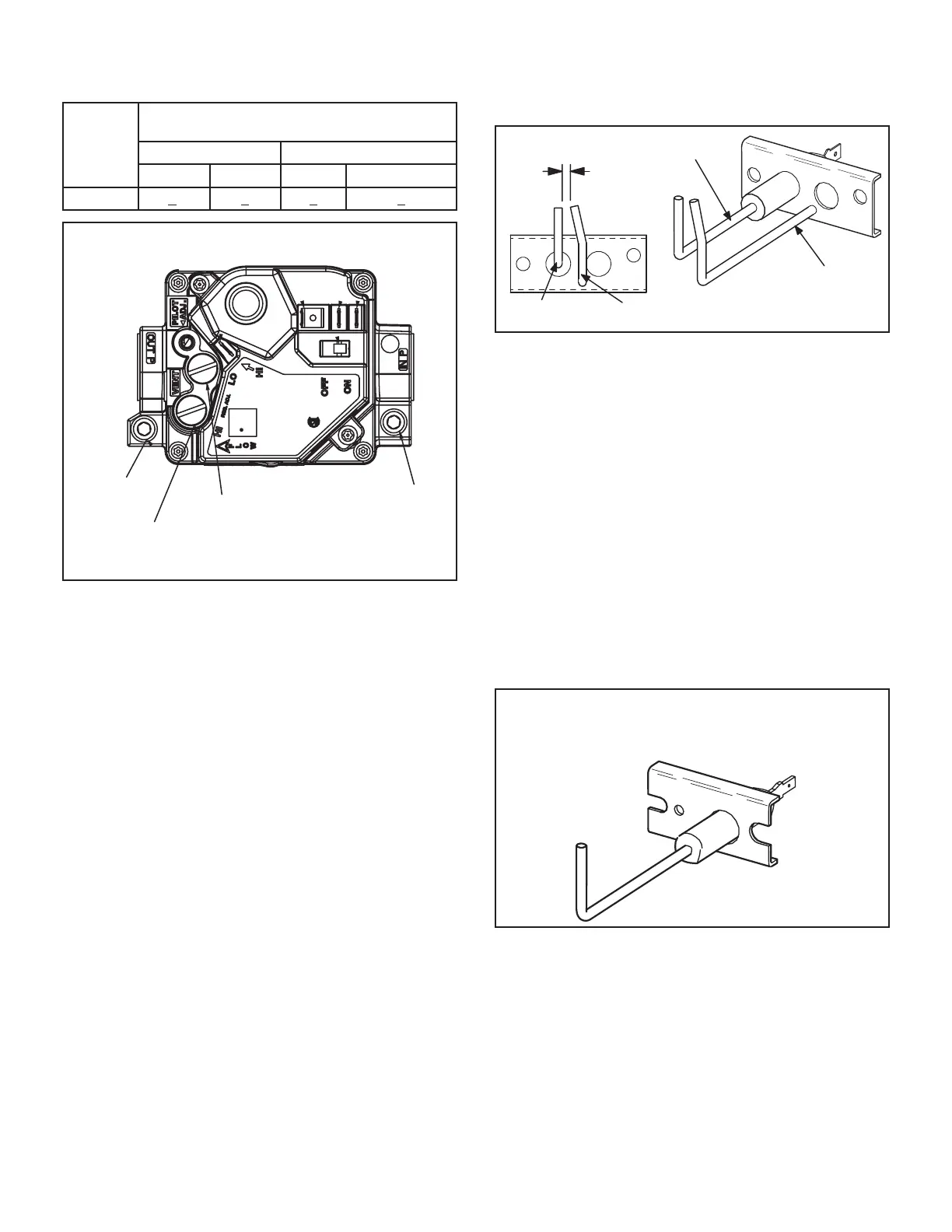

11-Spark Electrodes

An electrode assembly is used for ignition spark. Two iden-

tical electrodes are used (one for each gas heat section).

The electrode is mounted through holes on the left-most

end of the burner support. The electrode tip protrudes into

assembly is fastened to burner supports and can be re-

moved for service without removing any part of the burn-

ers.

burner to burner until all are lit.

The spark electrode is connected to the ignition control

by a 8 mm silicone-insulated stranded high voltage wire.

electrode end and female spark plug-type terminal on the

ignition control end

NOTE-IN ORDER TO MAXIMIZE SPARK ENERGY TO

ELECTRODE, HIGH VOLTAGE WIRE SHOULD

TOUCH UNIT CABINET AS LITTLE AS POSSIBLE.

GROUND

ELECTRODE

GROUND

ELECTRODE

.125” ± .015”

(3.2 mm ± .4 mm)

FIGURE 21

12-Flame Sensors

-

er support. The sensor is mounted through a hole in the

-

lope of the right most burner. The sensor assembly is fas-

tened to burner supports and can be removed for service

without removing any part of the burners.

-

diately.

-

tion control allows the gas valve to stay open as long as a

FIGURE 22

Loading...

Loading...