Page 6

LGT/LCT156, 180, 210, 240, 300

Shipping and Packing List

Package 1 of 1 contains:

1- Assembled unit

Check unit for shipping damage. Receiving party should

contact last carrier immediately if shipping damage is found.

General

These instructions are intended as a general guide and

do not supersede local codes in any way. Authorities

having jurisdiction should be consulted before

installation.

The LGT156H gas/electric packaged rooftop unit is

available in 169, 000, 260,000, & 360,000 Btuh heating

input. The LGT180, 210, 240, & 300 gas/electric

packaged rooftop units are available in 260,000,

360,000, or 480,000 Btuh heating inputs.

The LCT cooling packaged rooftop unit is the same basic

design as the LGT unit except for the heating section.

Optional electric heat is factory- or field-installed in LCT

units.

LGT and LCT units have identical refrigerant circuits with

respective 13, 15, 17‐1/2, 20 and 25 ton cooling

capacities. 156H units contain two compressors;

compressor 1 is two speed and compressor 2 is fixed

speed. 180H units contain three compressors; all are

fixed speed. 210, 240 and 300 units contain four

compressors; all are fixed speed compressors.

Units come standard with a factory-installed, all-aluminum

condenser coil.

Units are available with an optional hot gas reheat coil

which provides a dehumidifying mode of operation. Refer

to Reheat Operation section.

Units are available with variable air volume or single-zone

variable air volume. Refer to the 9

th

character of the

model number to determine type of blower:

V - Variable Air Volume

M - Single-Zone Variable Air Volume

Units use R410A, an ozone-friendly HFC refrigerant.

Refer to the Cooling Start-Up section for precautions

when installing unit.

WARNING

Electric shock hazard and danger of

explosion. Can cause injury, death or

product or property damage. Turn off

gas and electrical power to unit before

performing any maintenance or

servicing operations on the unit. Follow

lighting instructions attached to unit

when putting unit back into operation

and after service or maintenance.

Requirements

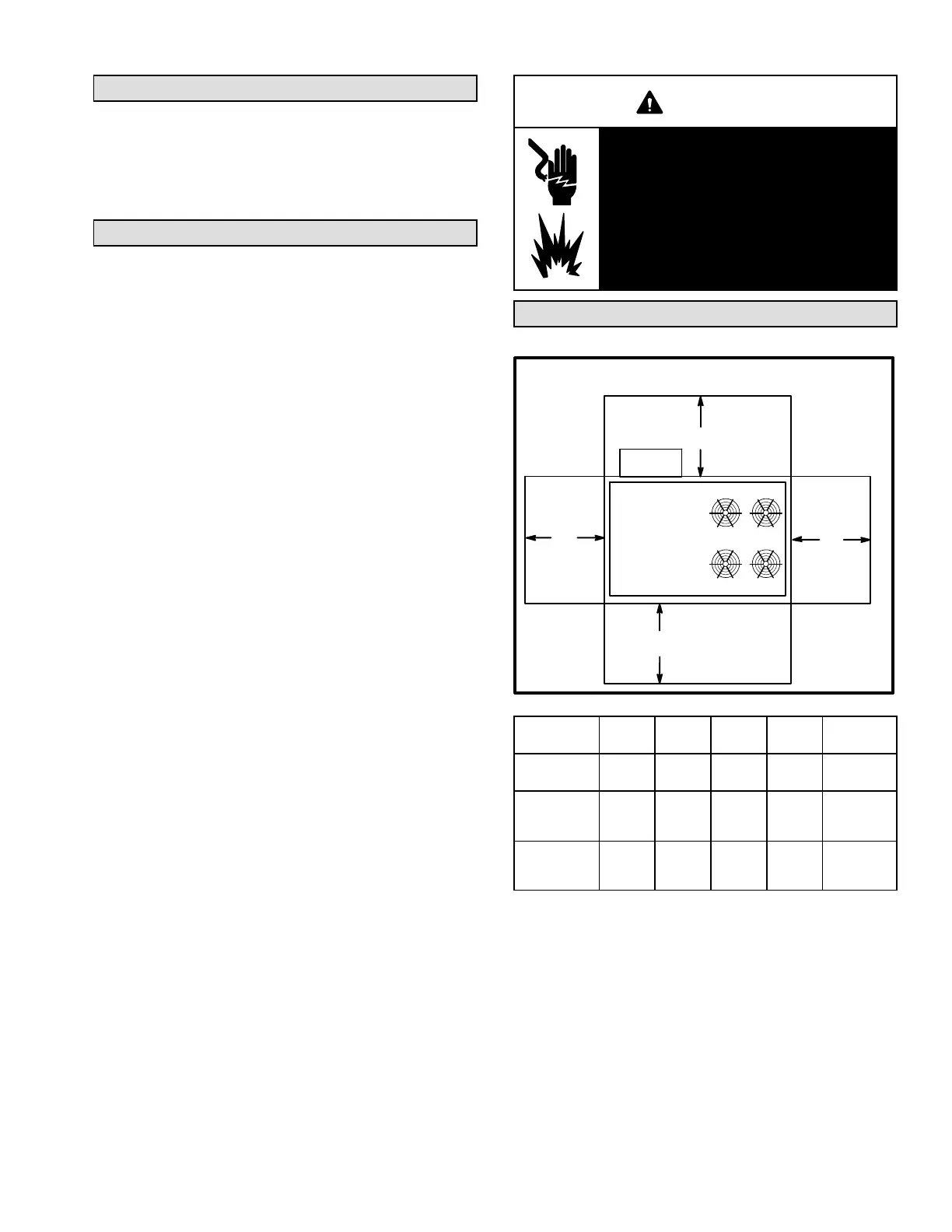

See figure 1 for unit clearances.

UNIT CLEARANCES

C

D

B

A

FIGURE 1

Optional

Outdoor

Air Hood

1

Unit

Clearance

A

in.(mm)

B

in.(mm)

C

in.(mm)

D

in.(mm)

Top

Clearance

Service

Clearance

60

(1524)

36

(914)

36

(914)

66

(1676)

Unob

structed

Clearance to

Combus

tibles

36

(914)

1 (25) 1 (25) 1 (25)

Unob

structed

Minimum

Operation

Clearance

36

(914)

36

(914)

36

(914)

41

(1041)

Unob

structed

Note - Entire perimeter of unit base requires support when elevated above

mounting surface.

1

Service Clearance - Required for removal of serviceable parts.

Clearance to Combustibles - Required clearance to combustible material

(gas units). On LCT units, see clearance to combustible materials outlined

on heater rating plate.

Minimum Operation Clearance - Required clearance for proper unit operation.

Loading...

Loading...