Page 31

High Pressure Switch S4

S4 is a N.C. auto-reset high pressure switch located on

the discharge line. The switch shuts o the compressor

when discharge pressure rises above the factory setting.

The switch on LRP14/16 series units is set to open at 590

+ 10 psi and close at 418 + 10 psi. S4 is not adjustable.

Float Switch

A oat switch is included with the downow kit or can be

ordered as an accessory (oat switch is factory installed

on the LRP16 series). The oat switch is designed to pre-

vent condensate water from overowing the condensate

pan due to a restriction in the condensate drain line. The

oat switch is eld-installed in the condensate drain pan

near the drain exit (oat switch is factory installed on the

LRP16 series). Refer to the installation instruction for the

oat switch kit or the downow kit for location and cutting

of the red wire located in the blower compartment.

ELECTRIC HEAT

Matchups and Ratings

Matchups and ratings are listed with “ELECTRICAL

DATA”.

Electric Heat Components

See gure 12 for electric heat parts arrangement.

Limit Switches 1, 2, 3 and 4

Limit switches 1, 2, 3 and 4 are N.C. auto-reset high

temperature limits located on the electric heat vest pan-

el. Each heating element is wired in series with a high

temperature limit. When the limit opens, the correspond-

ing heating element is de-energized. All other heating

elements remain energized. The limits will automatically

close when temperatures return to normal. Limit rating will

be on front side.

Heating Element HE1 through HE4

Heating elements are composed of helix-wound bare ni-

chrome wire exposed directly to the air stream. The ele-

ments are supported by insulators mounted to the wire

frame. Each element is energized independently by a

corresponding relay located on the heat vest panel. Once

energized, heat transfer is instantaneous.

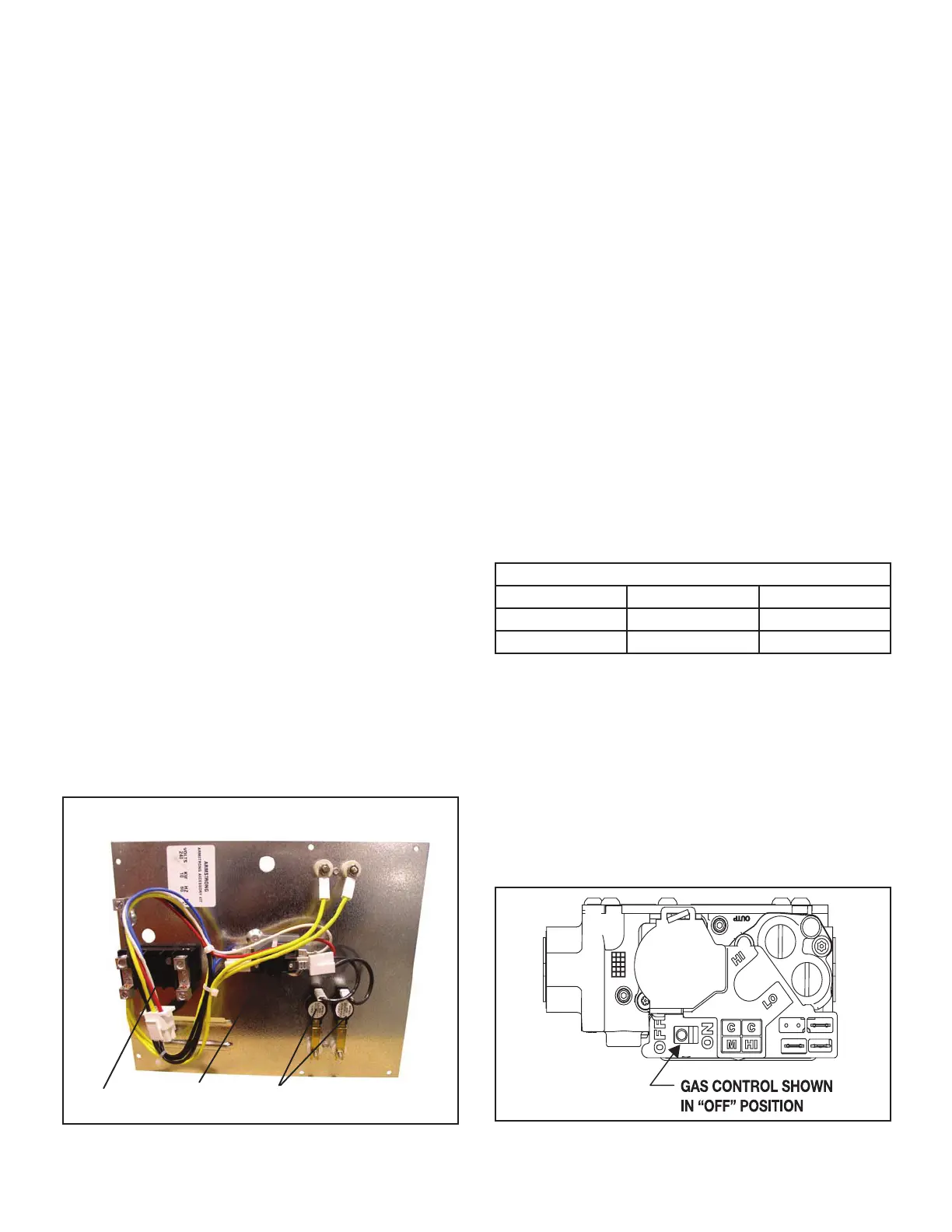

PHK VESTIBULE PARTS ARRANGEMENT

(PHK-10)

SEQUENCER

RELAY

PRIMARY

LIMITS

TB 2

FIGURE 12

Terminal Strip TB2 PHK-05, -07, -10

All heating elements require either a second-line voltage

power source or the use of the single-point power connection

kit. For electric heat sections without circuit breakers or fus-

es, line voltage connections are made to terminal strip TB2.

Sequencer Relays 1 and 2

Relays 1 and 2 are N.O. sequencer relays with a resis-

tive element for a coil and bi-metal disk which actuates

the contacts. The relays are located on the electric heat

vest panel and are energized by a 24V heating demand

(W1 and W2) via jack/plug P2 which is used to connect

electric heat to the blower control circuit. When energized,

the internal resistance heats the bi-metal disk causing the

contacts to close. When the relay is de-energized the disk

cools and the contacts open. The relays energize dierent

stages of heat, as well as the blower. The blower is always

rst on and last o.

NOTE - As of 2015, all electric heaters must be equipped

with a second relay to break the line voltage on the return

side so that a path for the electrical voltage is broken on

both sides if an element goes to ground.

Circuit Breaker CB1 and CB2 (option) PHK-15, -20

Line voltage connections are made to circuit breakers CB1

and CB2 in electric heat sections with circuit breakers. Ta-

ble 2 shows amp rating for each circuit breaker used. Two-

pole circuit breakers are used.

TABLE 4

Circuit Breakers

UNIT CB1 AMPS CB2 AMPS

PHK15CP 60 AMPS 30 AMPS

PHK20CP 60 AMPS 60 AMPS

GAS HEAT

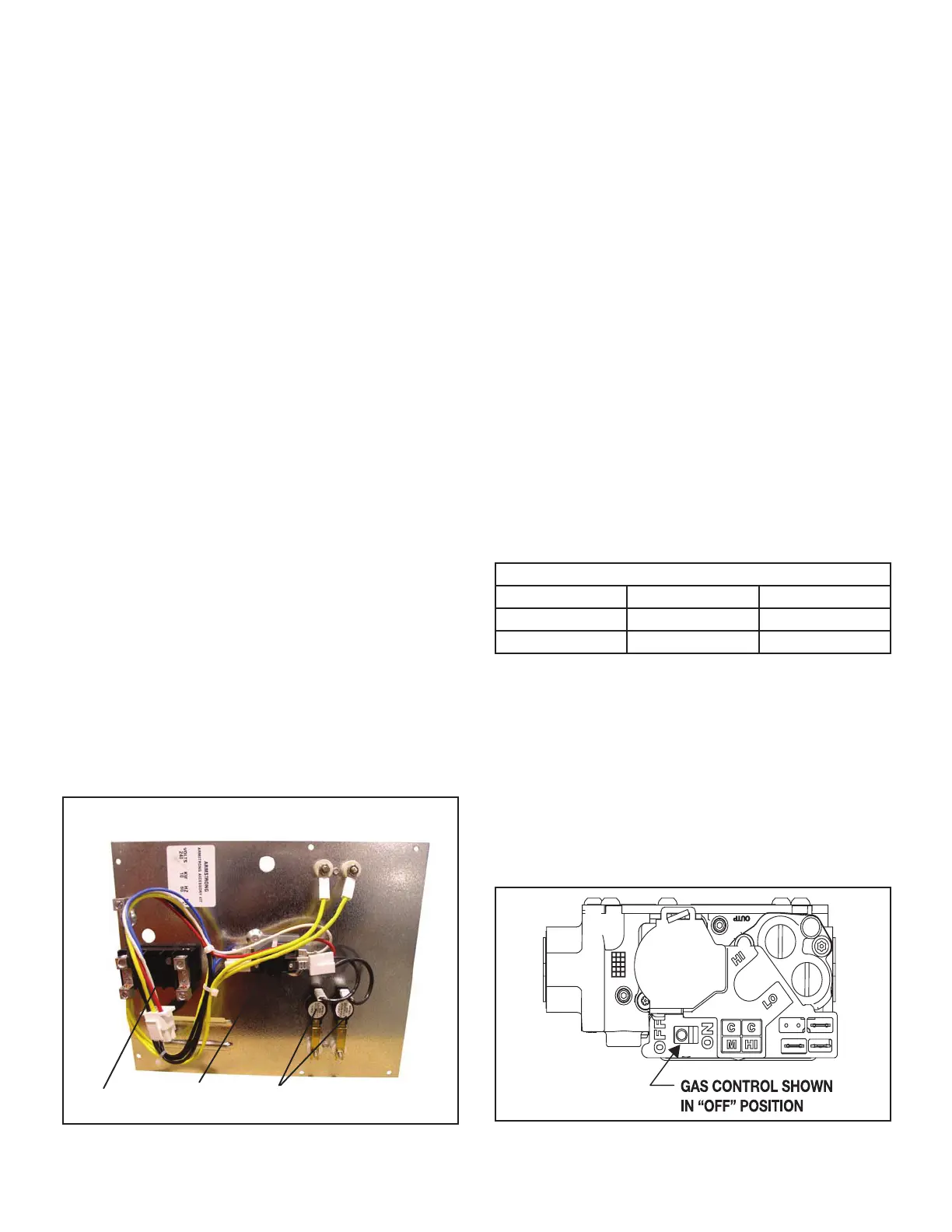

Gas Valve (GV1) LRP16GE Units

The LRP16GE uses a gas valve manufactured by

White-Rodgers. The valve is two-stage internally redun-

dant to assure safety shut o. If the valve must be re-

placed the same type valve must be used. The valve can

be converted to LP (see options gas specications for LP

kit) and is adjustable on both high and low re.

24VAC and gas control knob / switch are located on top

of the valve. Terminals on the gas valve are connected to

wires from the ignition control (A3). Inlet and outlet taps

are located on the valve.

FIGURE 13

Loading...

Loading...