Page 32

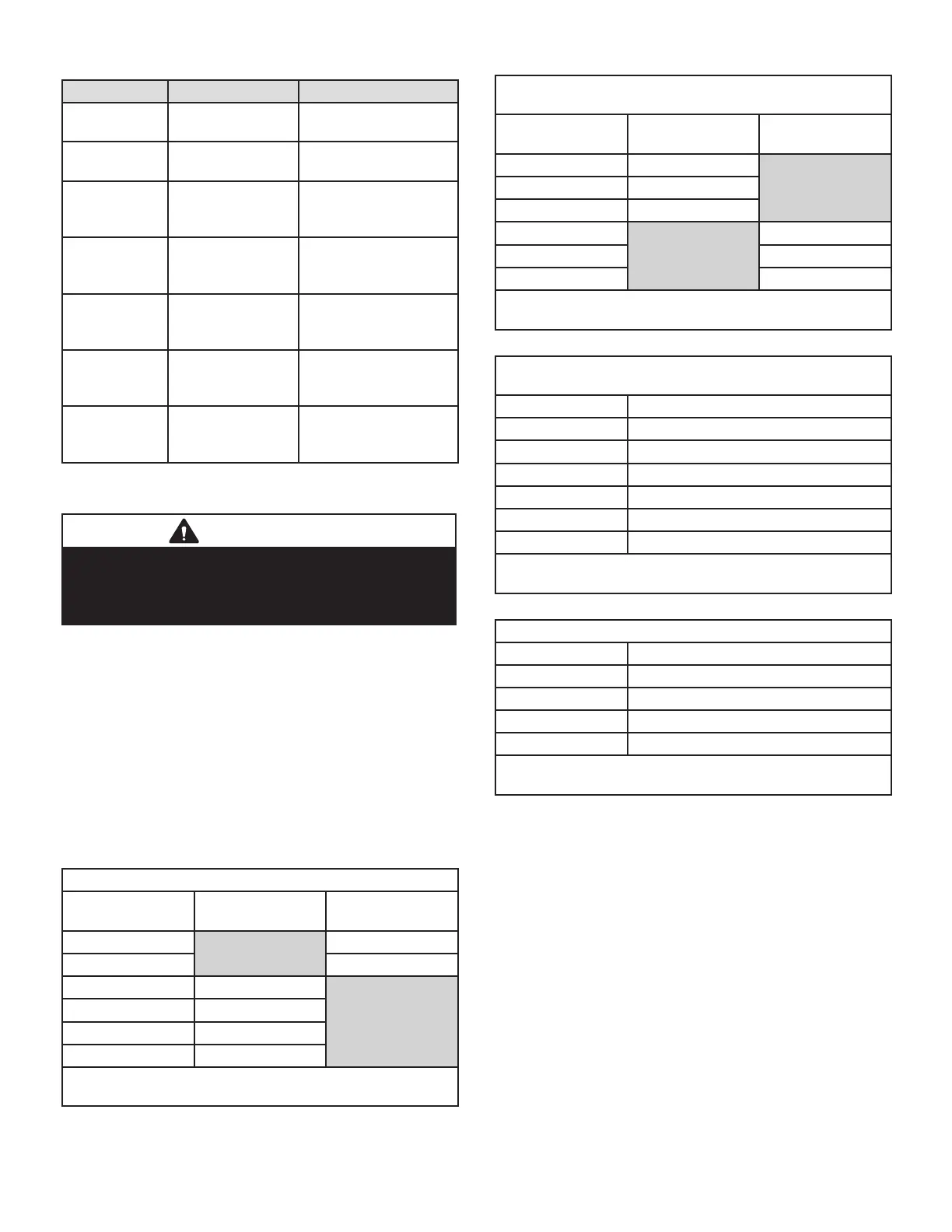

Control System Diagnostics

LED Status Flashing Rate Fault Description

Slow Flash

One ash per

second

Normal operation:

No call for heat

Fast Flash

Two ashes per

second

Normal operation:

Call for heat

2 Flash

Two ashes in

1 second with

1-second pause

System lockout:

Failed to detect or

sustain ame

3 Flash

Three ashes in

1.5 seconds with

1-second pause

Pressure switch senses

incorrect pressure or

gas valve coil is open

4 Flash

Four ashes in

2 seconds with

1-second pause

High limit or rollout

switch open

5 Flash

Five ashes in

2.5 seconds with

1-second pause

Flame sensed and gas

valve not energized

Steady –

Internal failure:

Micro-controller failure;

self-check

TABLE 5. Fault Codes

CHARGING

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take

care while handling this equipment and wear gloves and

protective clothing.

For maximum performance of the cooling system, the op-

erating temperatures and pressure should be checked and

subcooling determined at Standard ARI test conditions of

82° F outdoor temperature / 80° F indoor dry bulb / 67° F

indoor wet bulb.

For maximum performance of the heat pump, the oper-

ating temperatures and pressure should be checked and

subcooling determined at Standard ARI test conditions of

47° F outdoor temperature / 70° F indoor dry bulb.

If subcooling measurement deviates, refrigerant charge

should be adjusted accordingly for maximum performance.

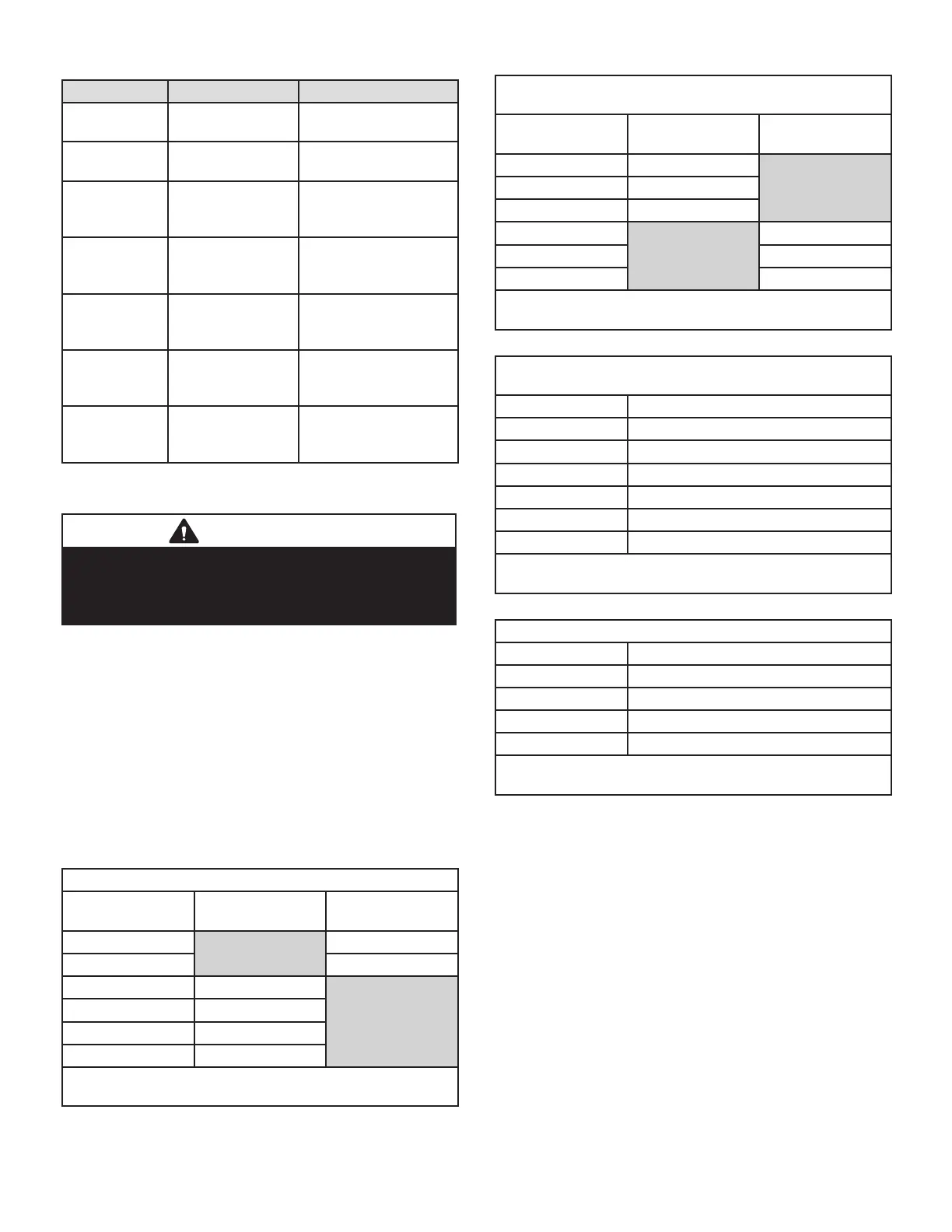

TABLE 6

AC Unit Cooling System Performance Values - LRP14

Model

Suction Superheat

+ / - 3°

Liquid Subcooling

+ / - 2°

2 Ton 10

2.5 Ton 14

3 Ton 13

3.5 Ton 12

4 Ton 14

5 Ton 17

Based on outdoor ambient temperature of 82º F and indoor

entering air of 80º F db, 67º F wb.

TABLE 7

Heat Pump Cooling System Performance Values -

LRP14HP / LRP16HP

Model

Suction Superheat

+ / - 3°

Liquid Subcooling

+ / - 2°

2 Ton 18

2.5 Ton 16

3 Ton 14

3.5 Ton 9

4 Ton 8

5 Ton 5

Based on outdoor ambient temperature of 82º F and indoor

entering air of 80º F db, 67º F wb.

TABLE 8

Heat Pump Heating System Performance Values -

LRP14HP / LRP16HP

Model Liquid Subcooling + / - 2°

2 Ton 25

2.5 Ton 15

3 Ton 11

3.5 Ton 22

4 Ton 24

5 Ton 28

Based on outdoor ambient temperature of 47º F and indoor

entering air of 70º F db.

TABLE 9

Unit Cooling System Performance Values - LRP16GE

Model Liquid Subcooling + / - 3°

2 Ton 10

3 Ton 12

4 Ton 10

5 Ton 9

Based on outdoor ambient temperature of 82º F and indoor

entering air of 80º F db, 67º F wb.

MAINTENANCE

The heating and air conditioning system should be inspect-

ed and maintained twice each year (before the start of the

cooling and heating seasons) by a licensed professional

HVAC technician. The technician is expected to check the

following items. These checks may only be conducted

by a licensed professional HVAC technician.

1 - Inspect component wiring for loose, worn or

damaged connections. Check for any rubbing or

pinching of wires. Conrm proper voltage plus

amperage of outdoor unit.

2 - Check the cleanliness of fan and blade condition

(cracks) and clean or replace them, if necessary.

3 - Inspect drain pan for debris and clean as necessary.

4 - Inspect the condition of refrigerant piping and conrm

that pipes are not rubbing copper-to-copper. Also,

check the condition of the insulation on the refrigerant

lines. Repair, correct, or replace as necessary.

Loading...

Loading...