Page 30

TABLE 3

Defrost Control Diagnostic LEDs

Mode

Green LED

(DS2)

Red LED

(DS1)

No Power to

Control

OFF OFF

Normal Operation /

Power to Control

Simultaneous Slow Flash

Anti-Short Cycle

Lockout

Alternating Slow Flash

Low Pressure

Switch Fault

OFF Slow Flash

Low Pressure

Switch Lockout

OFF ON

High Pressure

Switch Fault

Slow Flash OFF

High Pressure

Switch Lockout

ON OFF

BLOWER COMPARTMENT

Access panels can easily be removed for service.

Blower Wheel

Blower wheel size varies between models. See SPECIFI-

CATIONS.

WARNING

Disconnect power from unit and wait at least

ve minutes to allow capacitors to discharge

before attempting to adjust motor speed tap

settings. Failure to wait may cause personal

injury or death.

REFRIGERATION COMPONENTS

Compressor B1 – LRP14 Units

LRP14GE/GN and LRP14AC (-024 and -030 models) uti-

lize a rotary compressor. All other LRP14 models utilize a

scroll compressor. Compressors are energized by the K1

contactor found in the unit control box. Compressor spec-

ications are found in the “ELECTRICAL DATA” section in

this manual.

Compressor B1 – LRP16GE/HP Units

All LRP16GE units utilize a two-stage Copeland scroll

compressor. Compressors are energized by the K1 con-

tactor found in the unit control box. Compressor speci-

cations are found in the “ELECTRICAL DATA” section in

this manual.

WARNING

Electrical shock hazard. Compressor must be grounded.

Do not operate without protective cover over terminals.

Disconnect power before removing protective cover.

Discharge capacitors before servicing unit. Failure to

follow these precautions could cause electrical shock

resulting in injury or death.

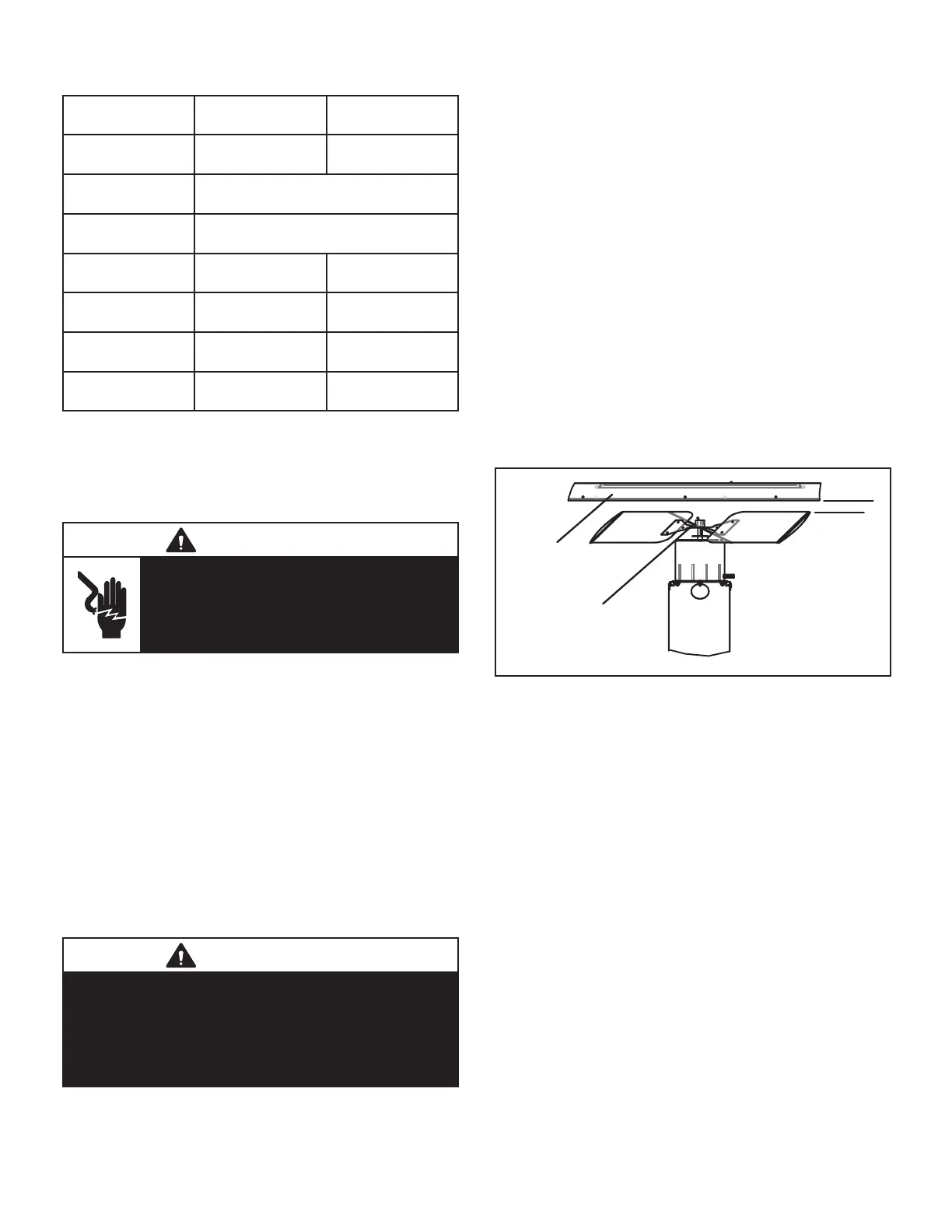

Condenser Fan B4 / Fan Motor B3 – LRP14 Units

LRP14 series units are equipped with a constant torque

blower motor. The constant torque motor is capable of

maintaining a specied CFM throughout the external

static range. Indoor fans are equipped with a permanent

magnet constant torque motor. These motors remain en-

ergized and are controlled by 24V signals. For high static

applications, use Tap 3 for cooling speed and Tap 5 for

heating speed.

All LRP14 series units use single phase condenser fan

motors. Specications for the condenser fans are at the

front of this manual. See gure 11 for fan and motor re-

placement dimensions.

Condenser Fan B4 / Fan Motor B3 – LRP16GE/HP Units

LRP16GE/HP units are equipped with a variable-speed di-

rect-drive blower operated by a variable-speed ECM mo-

tor. The ECM motor maintains a specied air volume from

0 through 0.80 in. w.g. static range.

All LRP16GE/HP units use single phase condenser fan

motors. Specications for the condenser fans are at the

front of this manual. See gure 11 for fan and motor re-

placement dimensions.

HUB AND

SHAFT SHOULD

BE FLUSH

FAN GUARD

1 1/2”

FIGURE 11

Reversing Valve L1

Reversing valve L1 has a 24 volt solenoid coil which re-

verses refrigerant flow during unit operation in all

LRP14HP and LRP16HP units. The reversing valve is in

the refrigerant circuit vapor line. The reversing valve coil

is energized during cooling demand and during defrost.

Low Pressure Switch S79 (LRP14GE, AC, LRP16GE

Units)

S79 is a N.C. auto-reset low pressure switch located on

the suction line. The switch shuts o the compressor when

suction pressure falls below the factory setting. The switch

is ignored during the rst 90 seconds of compressor start

up and during defrost operation. On the LRP14/16 series

units, the switch is set to open at 25 ± 5 psi and close at

40 ± 5 psi. S79 is not adjustable.

Loss of Charge Pressure Switch S79 (LRP14HP-02 –

LRP16HP Units)

The low pressure switch is an auto-reset N.C. switch that

opens on pressure drop. The switch is wired into the de-

frost board low pressure terminals and is located on the

liquid (high pressure) line . When suction pressure drops

to 40 psig (275.8 kPa) the switch opens and the compres-

sor is de-energized. When suction pressure rises to 90

psig (620.5 kPa) the pressure switch will close.

Loading...

Loading...