Page 33

5 - Test capacitor. Replace as necessary.

6 - Inspect contactor contacts for pitting or burn marks.

Replace as necessary.

7 - Check fan motor for worn bearings/bushings.

Replace as necessary.

8 - Inspect and clean coils, if necessary and note any

damage to coils or signs of leakage.

Filters

1 - Internal lter kits containing lter rails for 1 in. thick

lters are available. Filters are not provided and

must be eld supplied. A lter is required, whether

installed in the unit, in the ductwork or behind a lter

grill in the conditioned area.

NOTE - If PCO is installed, an internal lter kit is not rec-

ommended.

2 - Filters should be inspected monthly. Replace

disposable lters or clean permanent-type lters as

necessary. Dirty lters are the most common cause

of inadequate heating or cooling performance.

Replace existing lter with a lter of like type and

size. DO NOT replace a permanent-type lter with

a disposable lter. Install new/clean lters with the

arrows on the side pointing in the direction of airow.

Healthy Climate® Photocatalytic Oxidation (PCO) Air

Purication Accessory (LRP16 Series Only)

1 - The Healthy Climate® PCO cartridge and UVA

lamp require annual replacement. An annual

maintenance kit is available that includes the PCO

cartridge and UVA lamp. More frequent replacement

may be required in applications with heavier dust or

dirt loads or in applications where a lower MERV

lter is installed before the Healthy Climate® PCO

cartridge. The eld supplied lter should be changed

at least annually, or according to the manufacturers

recommended replacement cycle.

General System Test with System Operating

1 - Perform a general system test. Turn on the air

conditioner to check operating functions such as

the startup and shuto operation. Check for unusual

noises or odors, and measure indoor/outdoor

temperatures and system pressures as needed.

Check the refrigerant charge per the charging

sticker information on the unit.

2 - Refer to the nameplate to determine the correct

temperature rise for all gas units (GE / DF).

3 - Verify that system total static pressure and airow

settings are within specic operating parameters.

4 - Verify correct temperature drop across indoor coil.

POST START-UP CHECKLIST (GAS)

After the control circuit has been energized and the heat-

ing section is operating, make the following checks:

1 - Use soap solution to check for gas leaks in the unit

piping as well as the supply piping.

2 - Check the supply gas pressure. It must be within the

limits shown on rating nameplate. Supply pressure

should be checked with all gas appliances in the

building at full re. At no time should the supply gas

pressure exceed 10.5 inches w.c., nor drop below

5.0 inches w.c. for natural gas units. For propane

gas, supply gas pressure should not drop below 11

inches w.c. If gas pressure is outside these limits,

contact your gas supplier for corrective action.

3 - Check for correct manifold gas pressures. See

Check and Adjust Manifold Pressure.

4 - Adjust temperature rise to the range specied on

the rating plate.

Check and Adjust Manifold Pressure

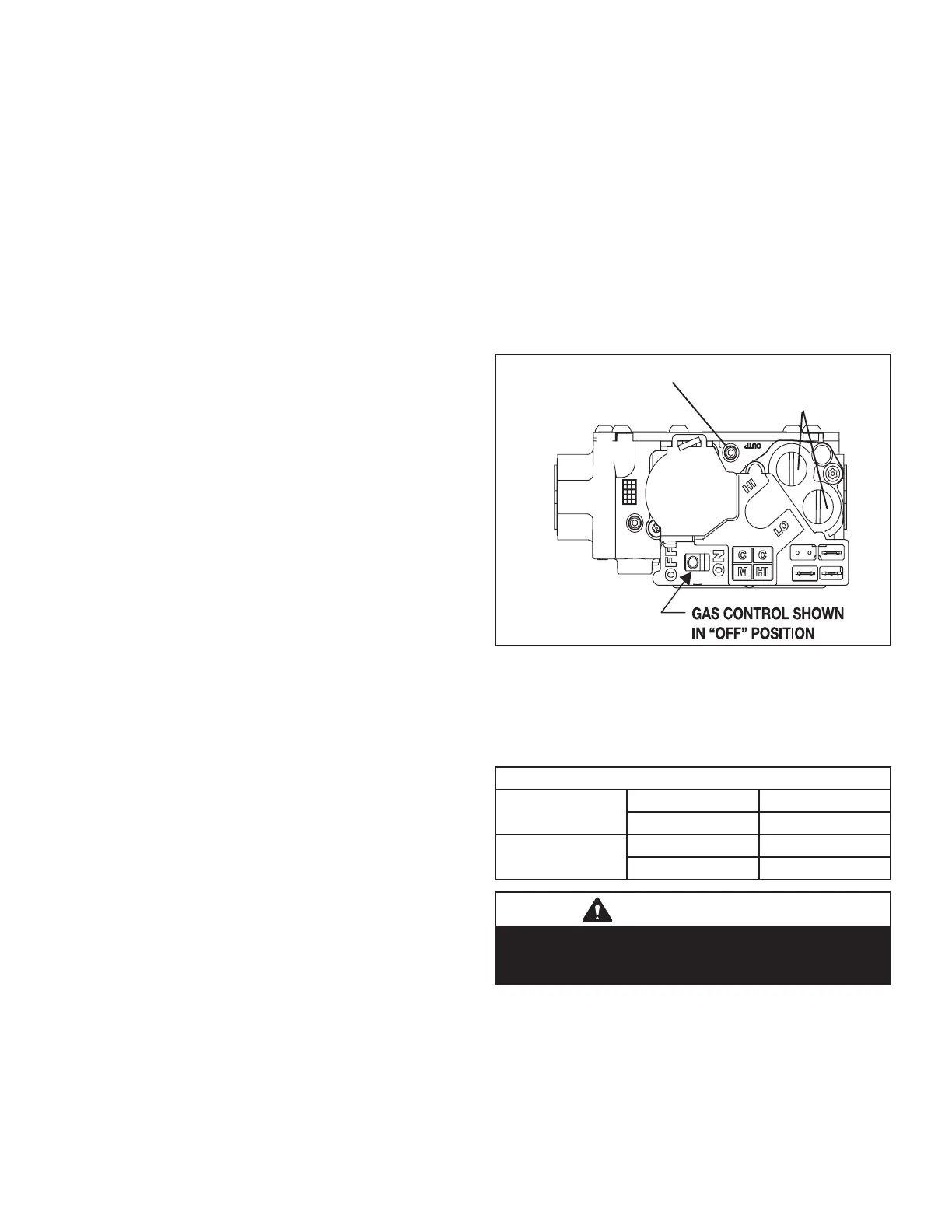

After line pressure has been checked and adjusted, check

manifold pressure. Refer to gure 14 for location of man-

ifold pressure adjustment screw and pressure tap outlet.

MANIFOLD PRESSURE

TEST TAP

REGULATOR

ADJUSTMENT

(UNDER CAP)

FIGURE 14

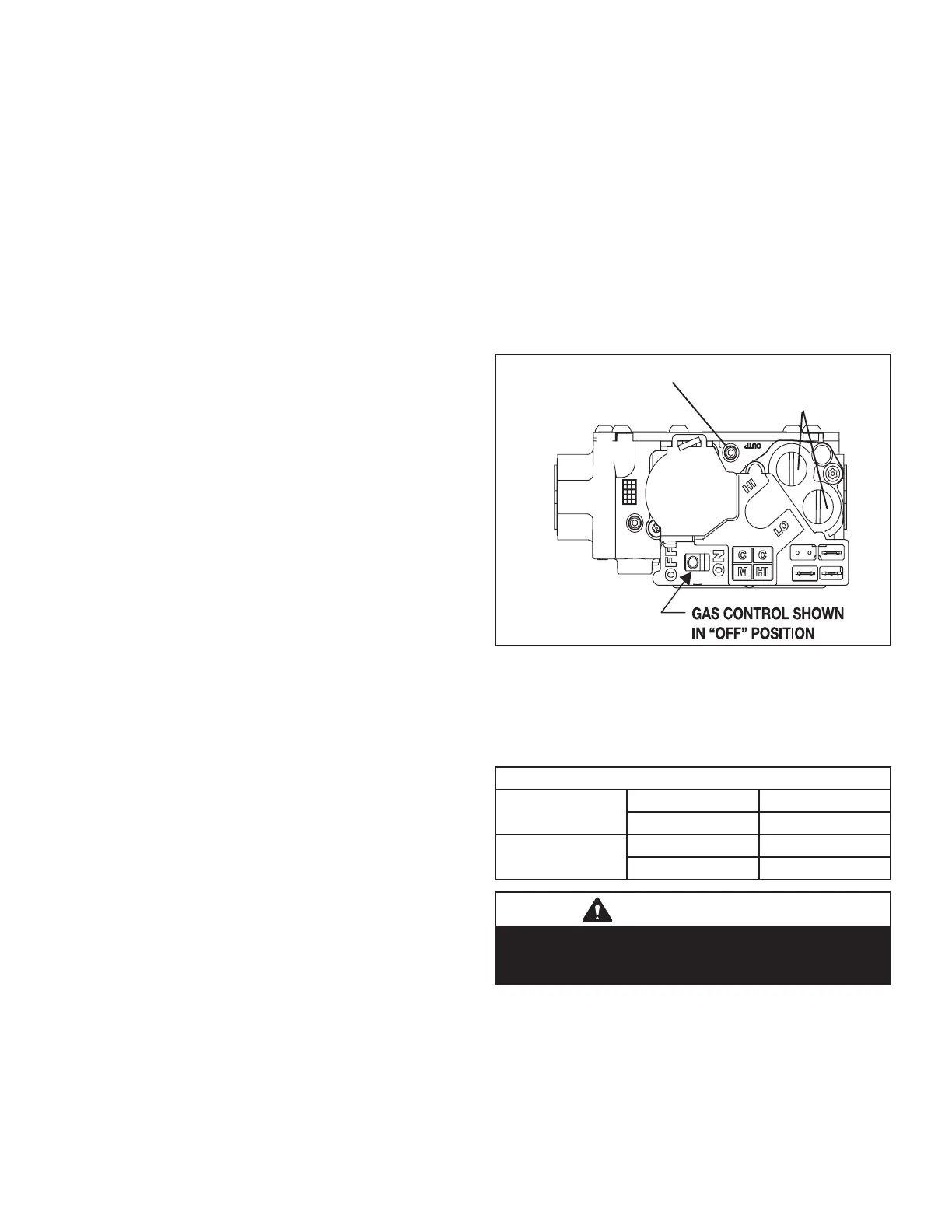

The gas valve is factory set and should not require adjust-

ment. See the table below for pressures. The gas valve

should completely and immediately cycle o in the event

of gas or power failure. The manual shut-o knob or switch

can be used to immediately shut o gas supply.

Manifold Pressure " w.c.

1st Stage Heat

Natural 2.0 ± 0.3

LP 5.6 ± 0.3

2nd Stage Heat

Natural 3.5 ± 0.3

LP 10.0 ± 0.5

IMPORTANT

For safety, connect a shut-o valve between the

manometer and the gas tap to permit shut o of gas

pressure to the manometer.

1 - Connect a test gauge to the outlet pressure tap on

the gas valve. Start the unit and allow ve minutes

for the unit to reach steady state.

2 - While waiting for the unit to stabilize, notice the

ame. The ame should be stable without ashback

and should not lift from the burner head. Natural

gas should burn blue. L.P. gas should burn mostly

blue with some orange streaks.

Loading...

Loading...