Page 25

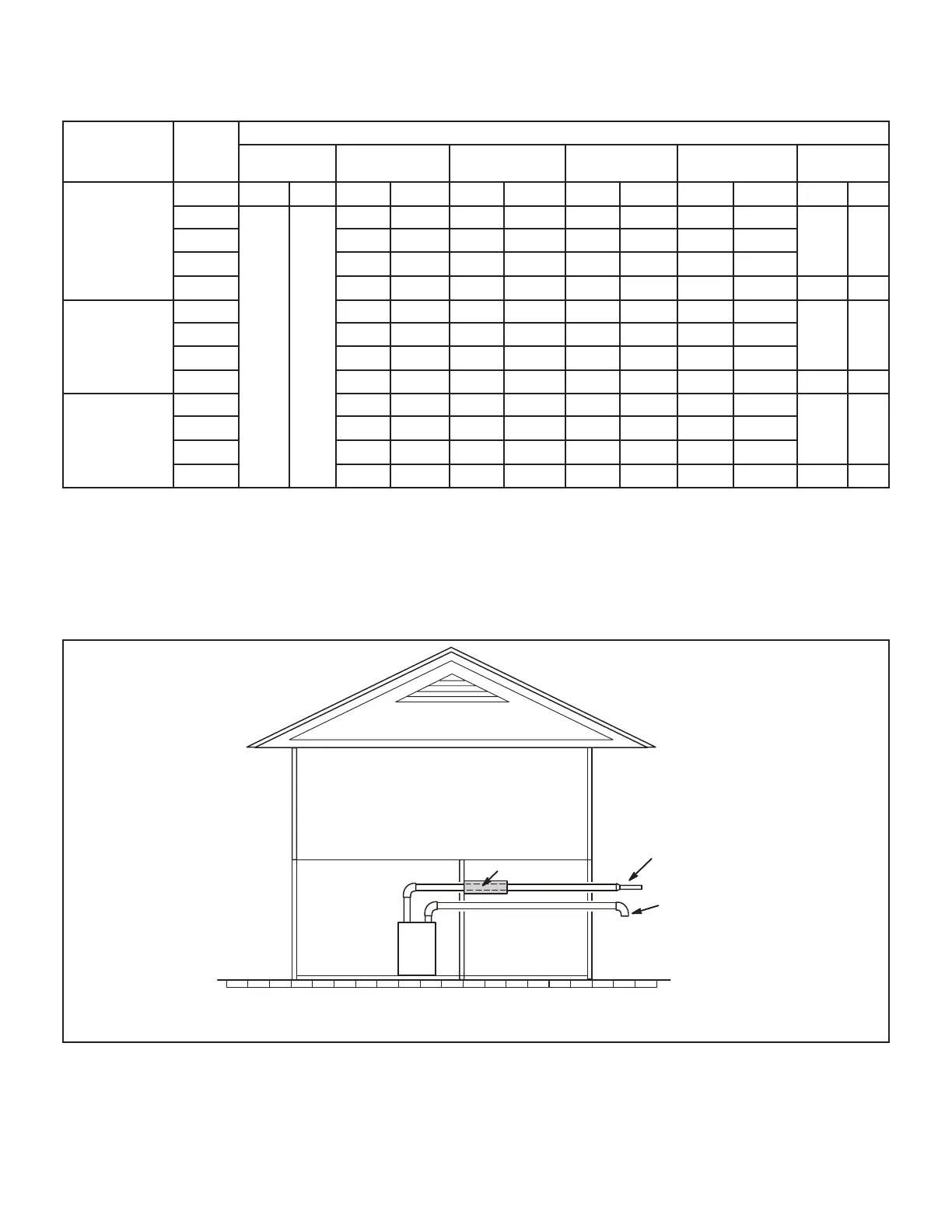

TABLE 7

Maximum Allowable Exhaust Vent Pipe Length (in ft.)

3

Without Insulation In Unconditioned Space For

Winter Design Temperatures Single - Stage High Eciency Furnace

Winter

Design

Temp

1

°F (°C)

Vent

Pipe

Diam

Unit Input Size

030

045 070 090 110 135

32 to 21

(0 to -6)

PVC

2

PP PVC

2

PP PVC

2

PP PVC

2

PP PVC

2

PP PVC

2

PP

1-1/2 in

N/A N/A

25 N/A 20 N/A N/A N/A N/A N/A

N/A N/A

2 in 18 16 31 28 50 48 30 30

2-1/2 in 13 N/A 24 N/A 42 N/A 56 N/A

3 in 9 9 18 18 35 35 47 47 42 42

20 to 1

(-7 to -17)

1-1/2 IN 15 N/A 20 N/A N/A N/A N/A N/A

N/A N/A

2 in 9 8 18 16 32 29 30 30

2-1/2 in 5 N/A 13 N/A 24 N/A 34 N/A

3 in 1

1

8 8 19 19 26 26 23 23

0 to -20

(-18 to -29)

1-1/2 in 10 N/A 15 N/A N/A N/A N/A N/A

N/A N/A

2 in 5

3

12 10 22 19 30 27

2-1/2 in 1

N/A

7 N/A 15 N/A 22 N/A

3 in N/A

N/A

2 2 10 10 16 16

13 13

1Refer to 99% Minimum Design Temperature table provided in the current edition of the ASHRAE Fundamentals Handbook.

2 Poly-Propylene vent pipe (PP) by Duravent and Centrotherm.

NOTE - Concentric terminations are the equivalent of 5’ and should be considered when measuring pipe length.

NOTE - Maximum uninsulated vent lengths listed may include the termination(vent pipe exterior to the structure) and cannot ex-

ceed 5 linear feet or the maximum allowable intake or exhaust vent length listed in table 5 or 6 which ever is less.

NOTE - If insulation is required in an unconditioned space, it must be located on the pipe closest to the furnace. See gure31.

3 Vent length in the table is equivalent length. Each elbow is equivalent to 5ft of straight pipe and should be included when mea-

suring total length.

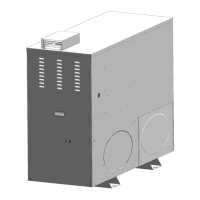

Conditioned

Space

Unconditioned

Space

Exhaust

Pipe

Intake

Pipe

Conditioned

Space

Pipe Insulation

Figure 31

Loading...

Loading...