Page 64

8 - Move gas valve switch to the ON position. See

FIGURE 48. Do not force.

9 - Replace the upper access panel.

10 - Turn on all electrical power to to the unit.

11 - Set the thermostat to desired setting.

NOTE - When unit is initially started, steps 1 through

11 may need to be repeated to purge air from gas

line.

12 - If the appliance will not operate, follow the

instructions “Turning O Gas to Unit” and call your

service technician or gas supplier.

Turning O Gas to Unit

1 - Set the thermostat to the lowest setting.

2 - Turn o all electrical power to the unit if service is to

be performed.

3 - Remove the upper access panel.

4 - Move the gas valve switch to the OFF position.

5 - Replace the upper access panel.

Failure To Operate

If the unit fails to operate, check the following:

1 - Is the thermostat calling for heat?

2 - Are access panels securely in place?

3 - Is the main disconnect switch closed?

4 - Is there a blown fuse?

5 - Is the lter dirty or plugged? Dirty or plugged lters

will cause the limit control to shut the unit o.

6 - Is gas turned on at the meter?

7 - Is the manual main shut-o valve open?

8 - Is the gas valve turned on?

9 - Is the unit ignition system in lock out? If the unit

locks out again, inspect the unit for blockages.

10 - Is blower harness connected to integrated control?

Furnace will not operate unless harness is

connected.

C-Safety or Emergency Shutdown

Turn o unit power. Close manual and main gas valves.

D-Extended Period Shutdown

Turn o thermostat or set to “UNOCCUPIED” mode. Close

all gas valves (both internal and external to unit) to guar-

antee no gas leak into combustion chamber. Turn o pow-

er to unit. All access panels and covers must be in place

and secured.

V-HEATING SYSTEM SERVICE CHECKS

A-CSA Certication

All units are CSA design certied without modications.

Refer to the SLP99UHV Installation Instruction.

B-Gas Piping

CAUTION

If a exible gas connector is required or allowed by the

authority that has jurisdiction, black iron pipe shall be

installed at the gas valve and extend outside the furnace

cabinet. The exible connector can then be added

between the black iron pipe and the gas supply line.

WARNING

Do not over torque (800 in-lbs) or under torque (350 in-

lbs) when attaching the gas piping to the gas valve.

Gas supply piping should not allow more than 0.5”W.C.

drop in pressure between gas meter and unit. Supply gas

pipe must not be smaller than unit gas connection.

Compounds used on gas piping threaded joints should be

resistant to action of liqueed petroleum gases.

C-Testing Gas Piping

IMPORTANT

In case emergency shutdown is required, turn o the

main shut-o valve and disconnect the main power to

unit. These controls should be properly labeled by the

installer.

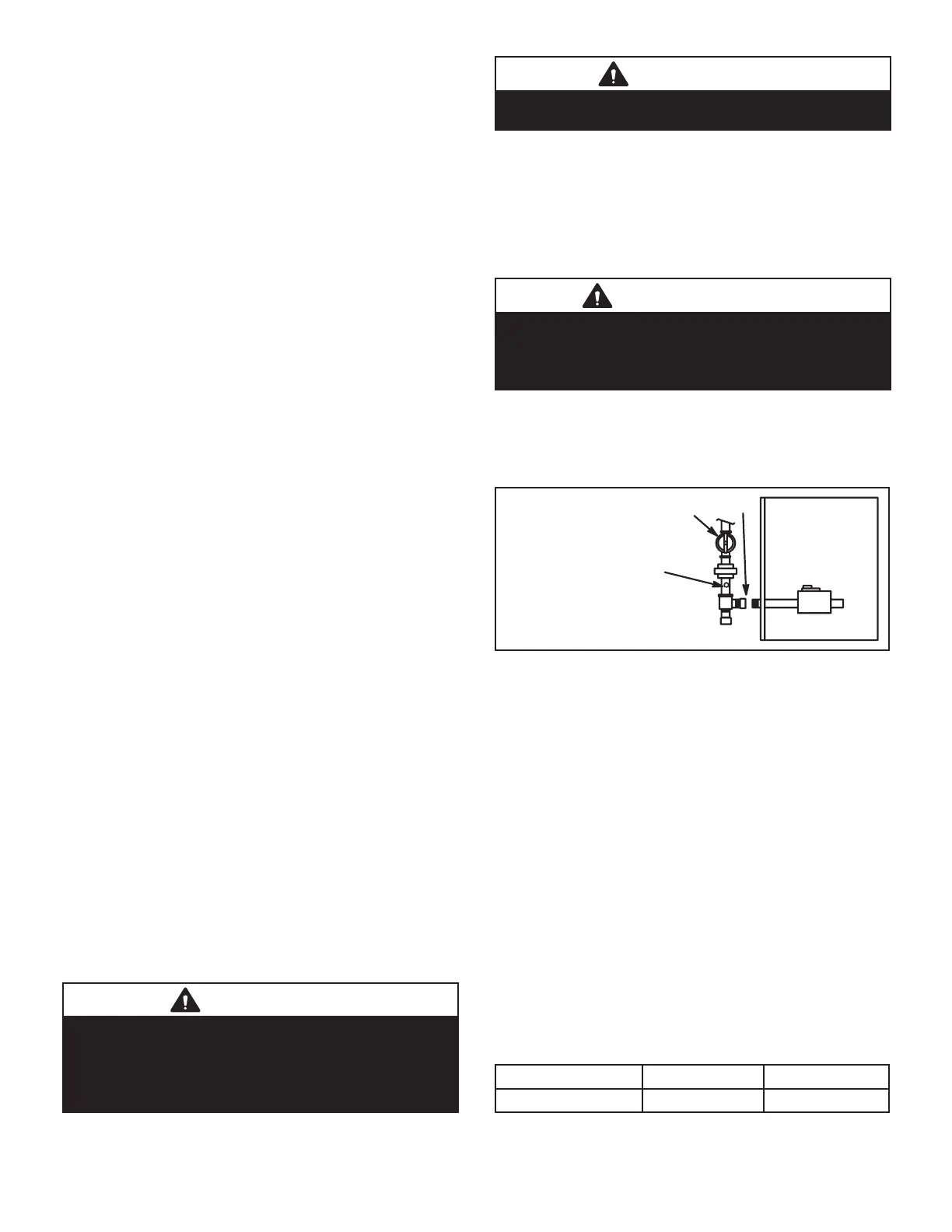

When pressure testing gas lines, the gas valve must be

disconnected and isolated. Gas valves can be damaged if

subjected to more than 0.5psig (14” W.C.). See FIGURE

49.

VALVE WILL NOT HOLD

NORMAL TEST PRESSURE

CAP

FURNACE

ISOLATE

GAS VALVE

N.P. T. PLUGGED TAP

FIGURE 49

When checking piping connections for gas leaks, use

preferred means. Kitchen detergents can cause harmful

corrosion on various metals used in gas piping. Use of a

specialty Gas Leak Detector is strongly recommended. It

is available through Lennox under part number 31B2001.

See Corp. 8411-L10, for further details.

Do not use matches, candles, ame or any other source o

ignition to check for gas leaks.

D-Testing Gas Supply Pressure

When testing supply gas pressure, connect test gauge to

supply pressure tap on the gas valve. See FIGURE 48.

Check gas line pressure with unit ring at maximum rate.

Low pressure may result in erratic operation or underre.

High pressure can result in permanent damage to gas

valve or overre. See TABLE 27 for operating pressure at

unit gas connection (line).

On multiple unit installations, each unit should be checked

separately, with and without units operating. Supply pres-

sure must fall within range listed in TABLE 27.

TABLE 27

All Units Natural LP/Propane

Line Pressure WC” 4.5 - 10.5

11.0 - 13.0

Loading...

Loading...