Page 16

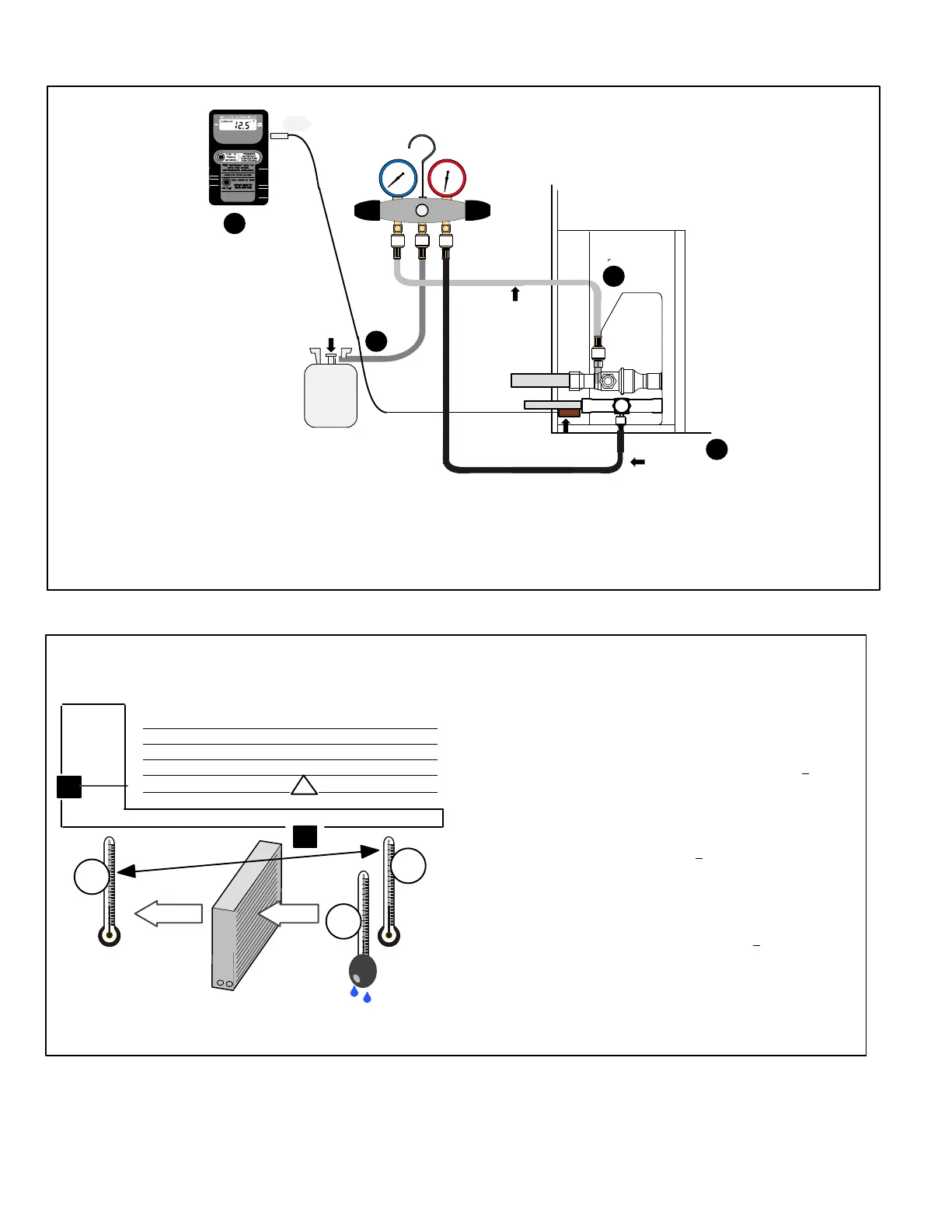

D − Charging 018, 024 −2 units & 030 through 060 −3 units

TO SUCTION

SERVICE VALVE

TO LIQUID

LINE SERVICE

VALVE

TEMPERATURE

SENSOR

QC RESTRICTOR

FITTING

REFRIGERANT

TANK

TEMPERATURE SENSOR

(LIQUID LINE)

MANIFOLD

GAUGE SET

A Close manifold gauge set valves and connect the center hose to an upright cylinder of R−410A.

B Connect the manifold gauge set’s low pressure side to the suction line service port.

C Connect the manifold gauge set’s high pressure side to the liquid line service port.

D Position temperature sensor on liquid line near liquid line service port.

OUTDOOR UNIT

CHARGING SYSTEM

A

B

C

D

FIGURE 17

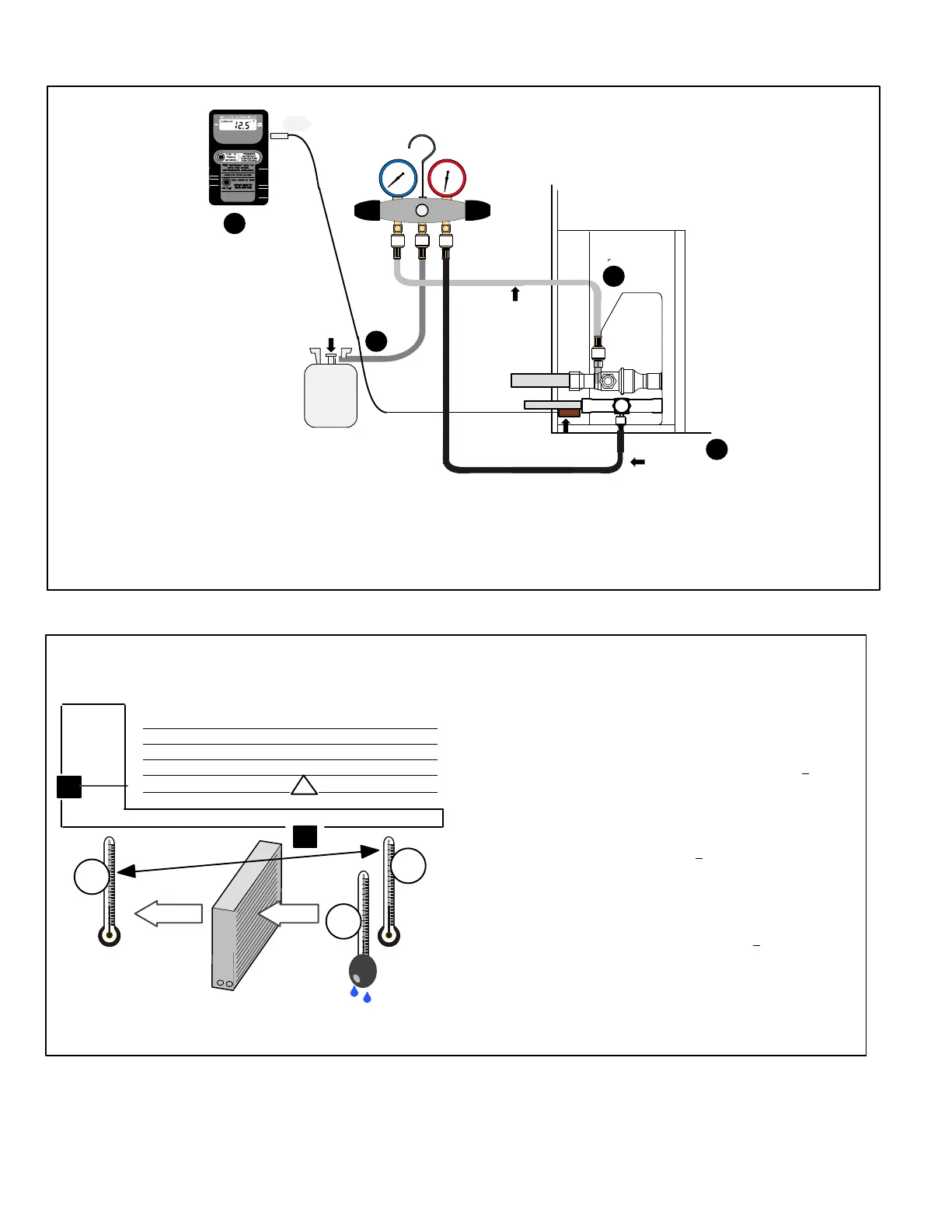

1. Determine the desired DTMeasure entering air temperature

using dry bulb (A) and wet bulb (B). DT is the intersecting value of A

and B in the table (see triangle).

2. Find temperature drop across coilMeasure the coil’s dry bulb

entering and leaving air temperatures (A and C). Temperature Drop

Formula: (T

Drop

) = A minus C.

3. Determine if fan needs adjustmentIf the difference between

the measured T

Drop

and the desired DT (T

Drop

–DT) is within +3º, no

adjustment is needed. See examples: Assume DT = 15 and A temp.

= 72º, these C temperatures would necessitate stated actions:

Cº T

Drop

– DT = ºF ACTION

53º 19 – 15 = 4 Increase the airflow

58º 14 – 15 = −1 (within +

3º range) no change

62º 10 – 15 = −5 Decrease the airflow

4. Adjust the fan speedSee indoor unit instructions to

increase/decrease fan speed.

Changing air flow affects all temperatures; recheck temperatures to

confirm that the temperature drop and DT are within +

3º.

DT

80 24 24 24 23 23 22 22 22 20 19 18 17 16 15

78 23 23 23 22 22 21 21 20 19 18 17 16 15 14

76 22 22 22 21 21 20 19 19 18 17 16 15 14 13

74 21 21 21 20 19 19 18 17 16 16 15 14 13 12

72 20 20 19 18 17 17 16 15 15 14 13 12 11 10

70 19 19 18 18 17 17 16 15 15 14 13 12 11 10

57 58 59 60 61 62 63 64 65 66 67 68 69 70

Temp.

of air

entering

indoor

coil ºF

INDOOR

COIL

DRY BULBDRY

BULB

WET

BULB

B

T

Drop

19º

A

Dry−bulb

Wet−bulb ºF

A

72º

B

64º

C

53º

air flowair flow

All temperatures are

expressed in ºF

INDOOR COIL AIRFLOW CHECK

Check indoor coil airflow using the Delta−T (

DT) process as illustrated.

FIGURE 18

Loading...

Loading...