Page 15

5 − Compare the subcooling value with those in table 4. If

subcooling is greater than shown, recover some refrig-

erant. If subcooling is less than shown, add some refrig-

erant. Be aware of the R−410A refrigerant cylinder. It will

be light maroon−colored. Refrigerant should be added

through the vapor line valve in the liquid state.

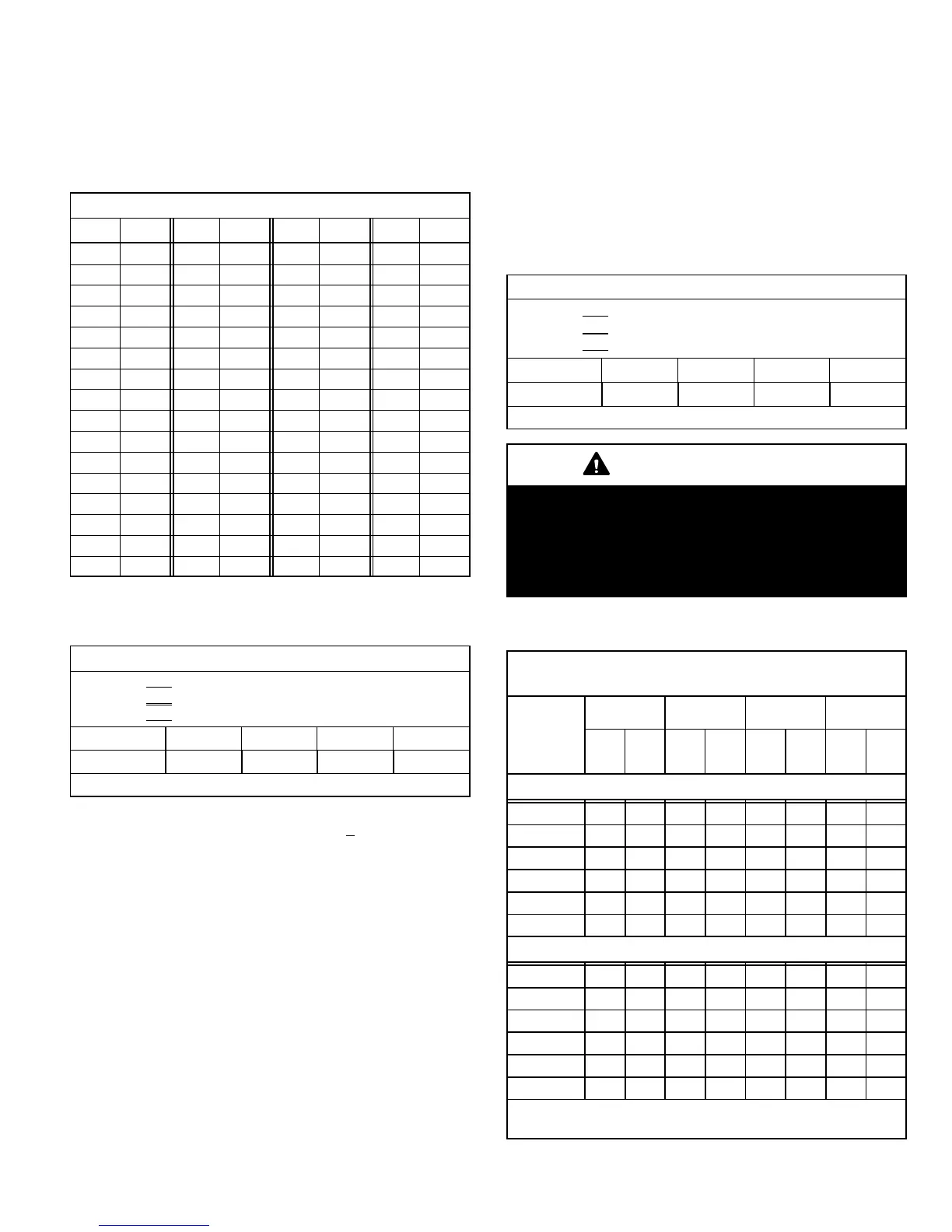

TABLE 3

R−410A Temperature (°F) − Pressure (Psig)

°F Psig °F Psig °F Psig °F Psig

32 100.8 64 181.6 96 299.4 126 451.8

34 105.0 66 187.7 98 308.2 128 463.5

36 109.2 68 194.1 100 317.2 130 475.6

38 113.6 70 200.6 102 326.4 132 487.8

40 118.0 72 207.2 104 335.7 134 500.2

42 122.6 74 214.0 106 345.3 136 512.9

44 127.3 76 220.9 108 355.0 138 525.8

46 132.2 78 228.0 110 365.0 140 539.0

48 137.1 80 235.3 112 375.1 142 552.3

50 142.2 82 242.7 114 385.4 144 565.9

52 147.4 84 250.3 116 396.0 146 579.8

54 152.8 86 258.0 118 406.7 148 593.8

56 158.2 88 266.0 120 417.7 150 608.1

58 163.9 90 274.1 122 428.8 152 622.7

60 169.6 92 282.3 124 440.2 154 637.5

62 195.5 94 290.8 126 451.8 156 652.4

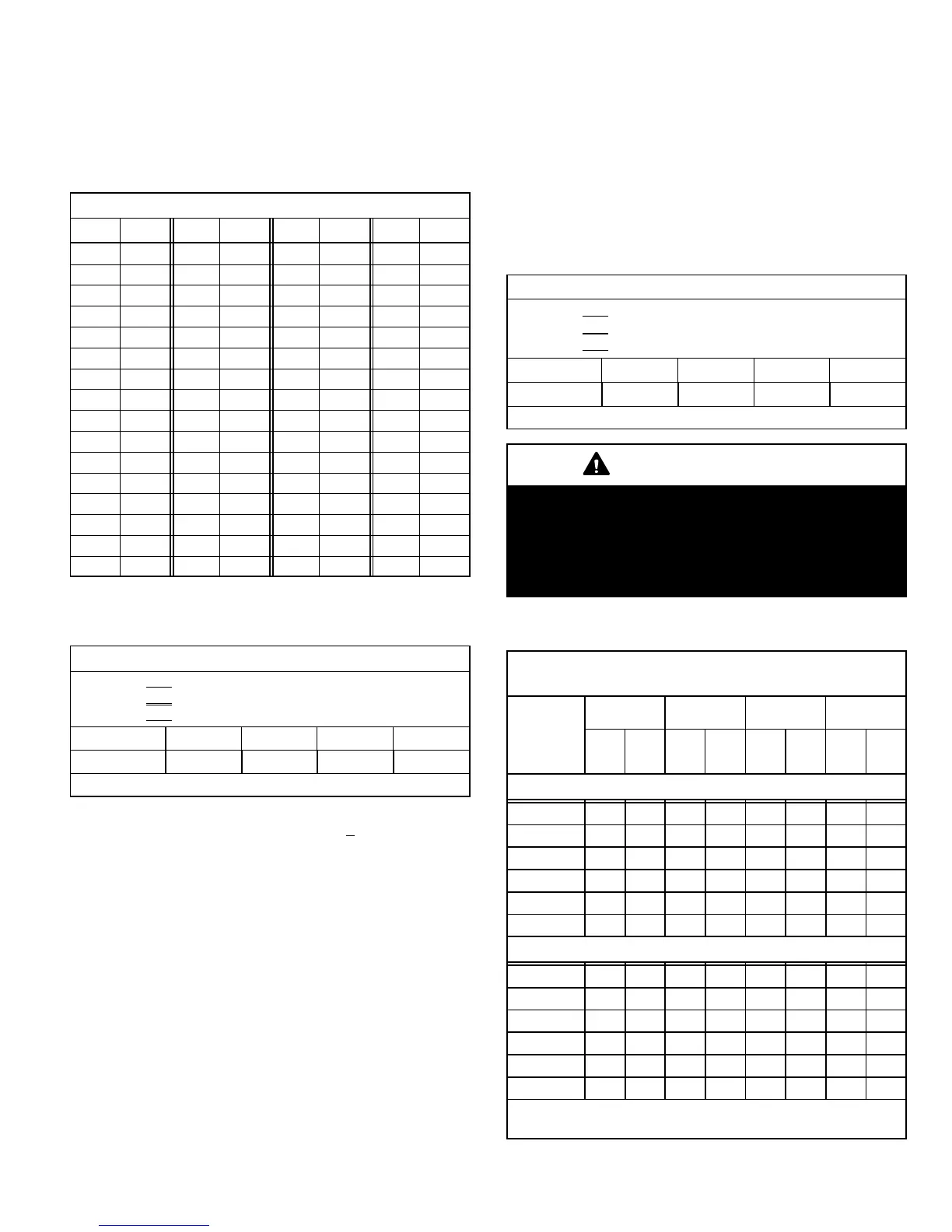

TABLE 4

XC16 Subcooling Values for Charging

Saturation Temperature

Liquid Line Temperature

=

Subcooling Value

Model −024 −036 −048 −060

°F (°C)* 5 (2.8) 6 (3.3) 6 (3.3) 9 (5)

*F: +/−1.0°; C: +/−0.5°

Charge Using the Approach Method,

TXV Systems

Outdoor Temperature > 65ºF (18ºC)

The following procedure is intended as a general guide and is

for use on expansion valve systems only. For best results, in-

door temperature should be 70°F (21°C) to 80°F (26°C).

Monitor system pressures while charging.

1 − Record outdoor ambient temperature using a digital

thermometer.

2 − Attach high pressure gauge set and operate unit for sev-

eral minutes to allow system pressures to stabilize.

3 − Compare stabilized pressures with those provided in

table 6, Normal Operating Pressures." Pressures high-

er than those listed indicate that the system is over-

charged. Pressures lower than those listed indicate that

the system is undercharged. A temperature/pressure

chart for R−410A refrigerant is provided in table 3 for

your convenience. Verify adjusted charge using the ap-

proach method.

NOTE − Use the same digital thermometer you used to

check the outdoor ambient temperature to check the liq-

uid line temperature.

4 − The difference between the ambient and liquid tempera-

tures should match values given in table 5. If the values

don’t agree with the those in table 5, add refrigerant to

lower the approach temperature, or recover refrigerant

from the system to increase the approach temperature.

Be aware of the R−410A refrigerant cylinder. It will be

light maroon−colored. Refrigerant should be added

through the vapor valve in the liquid state.

TABLE 5

XC16 Approach Values for Charging

Liquid Line Temperature

Outdoor Temperature

=

Approach Temperature

Model −024 −036 −048 −060

°F (°C)* 8 (4.4) 10 (5.6) 8 (4.4) 4 (2.2)

*F: +/−1.0°; C: +/−0.5°

IMPORTANT

Table 6 is not a procedure for charging the system but

may be used to perform maintenance checks. Minor

variations in these pressures may be due to differ-

ences in installations. Significant deviations could

mean that the system is not properly charged or that

a problem exists with some component in the system.

TABLE 6

Normal Operating Pressures In psig

(liquid +/− 10 and vapor+/− 5 PSIG)*

Temp. of

air enter-

−024 −036 −048 −060

ing out-

door coil

5F (5C)

Liq-

uid

Suc-

tion

Liq-

uid

Suc-

tion

Liq-

uid

Suc-

tion

Liq-

uid

Suc-

tion

First Stage (Low Capacity)

65 (18.3) 223 141 227 137 224 142 215 136

75 (23.9) 256 143 261 142 258 144 250 139

85 (29.4) 297 145 302 145 299 146 291 142

95 (35.0) 341 148 347 148 345 148 337 144

105 (40.6) 389 150 396 150 395 150 388 146

115 (46.1) 443 153 452 154 450 153 444 148

Second Stage (High Capacity)

65 (18.3) 232 140 244 132 235 135 220 130

75 (23.9) 268 143 278 139 269 137 256 133

85 (29.4) 310 145 321 142 313 139 299 136

95 (35.0) 356 147 368 144 361 141 347 138

105 (40.6) 405 149 419 147 412 143 402 141

115 (46.1) 459 152 476 150 471 146 462 143

*These are typical pressures only. Indoor indoor match up, in-

door air quality, and indoor load will cause the pressures to vary.

Loading...

Loading...